Multi-axis unmanned aerial vehicle

An unmanned aerial vehicle and rotor technology, applied in the field of aircraft, can solve the problems of single application, low load, easy damage, etc., and achieve the effect of convenient operation, high application value and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

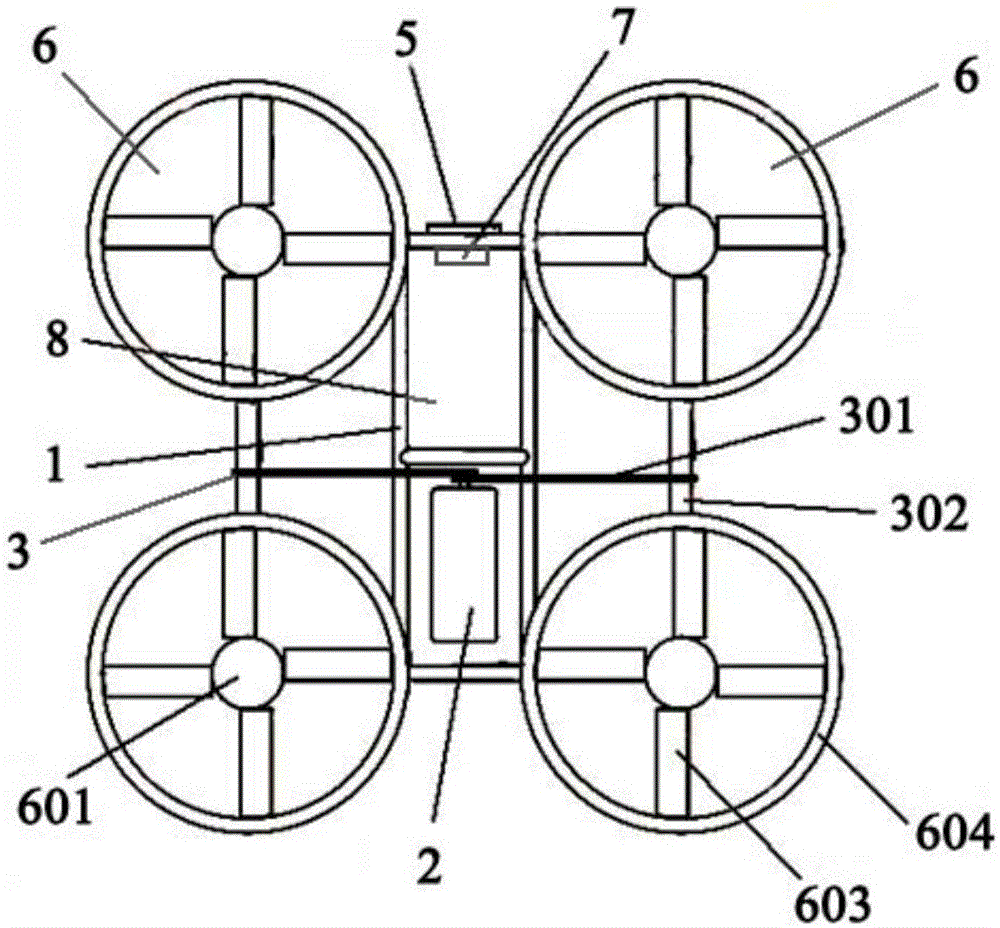

[0036] This embodiment provides a multi-axis unmanned aerial vehicle, which is characterized by comprising: a frame 1 and a power generating device 2, a power transmission device 3, a pitch changing device 4, a control device 5, and a plurality of rotors arranged on the frame Device 6, in which,

[0037] The power generating device 2 is connected to the power transmission device 3 for providing flight power;

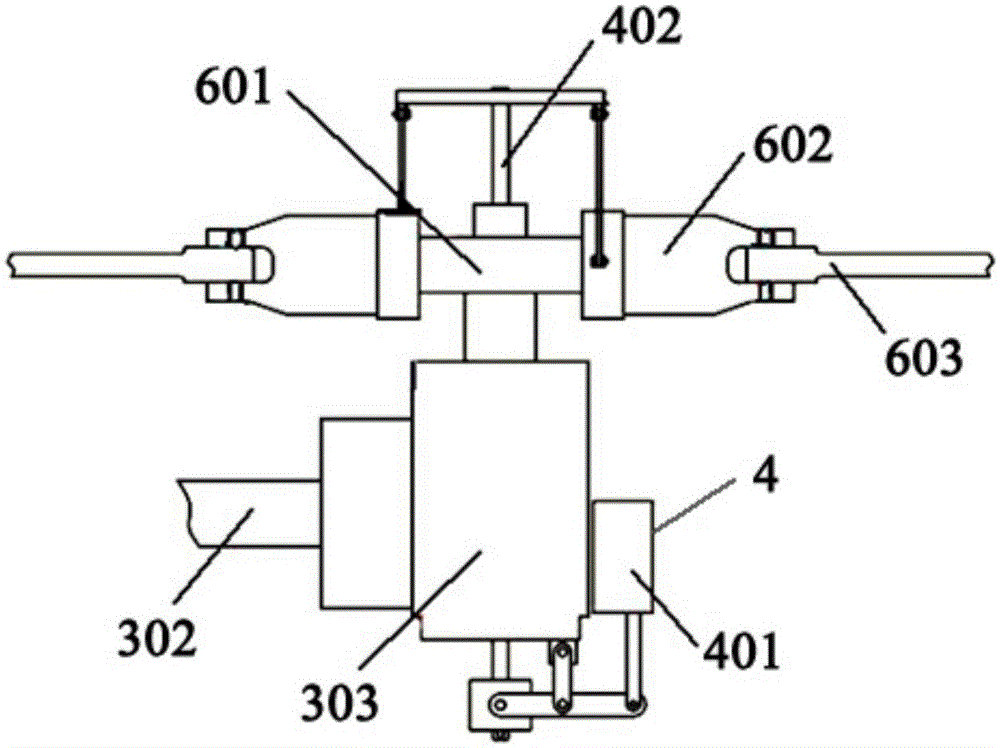

[0038] The power transmission device 3 includes a transmission belt 301, a transmission shaft 302, and a gear box 303 that are connected in sequence. The transmission belt 301 is connected to the power generation device 2, and the gear box 303 is connected to the rotor device 6. connection;

[0039] The rotor device 6 includes a rotor head 601, a propeller hub 602, and a propeller 603 that are connected in sequence, and the rotor head 601 is connected to the gear box 303;

[0040] The pitch changing device 4 includes a steering gear 401 and a pitch changing rod 402, the steerin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com