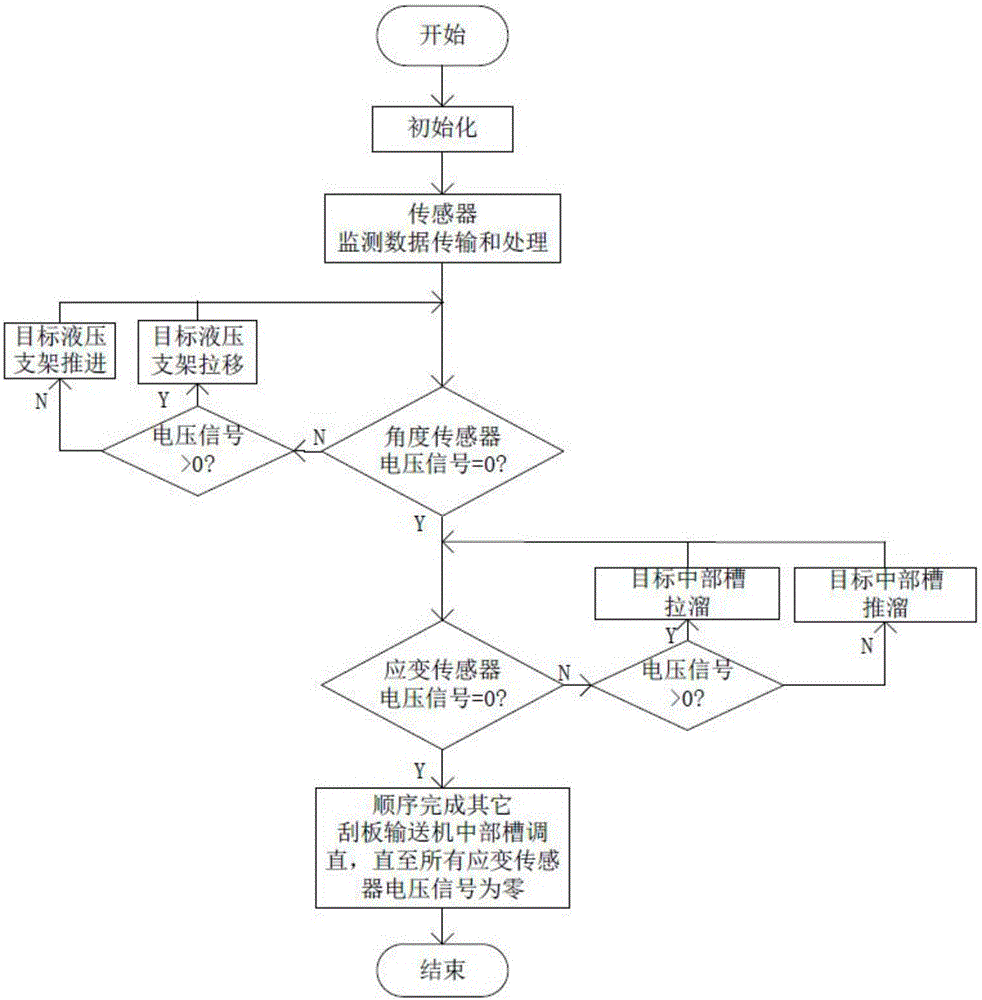

Automatic straightening device and method for scraper conveyer body of fully mechanized coal mining face

A scraper conveyor, fully mechanized mining face technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, can solve the problems of poor implementation feasibility, low accuracy, and poor practicability, and achieve shortening and straightening. Cycle time, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further explained below in conjunction with the accompanying drawings.

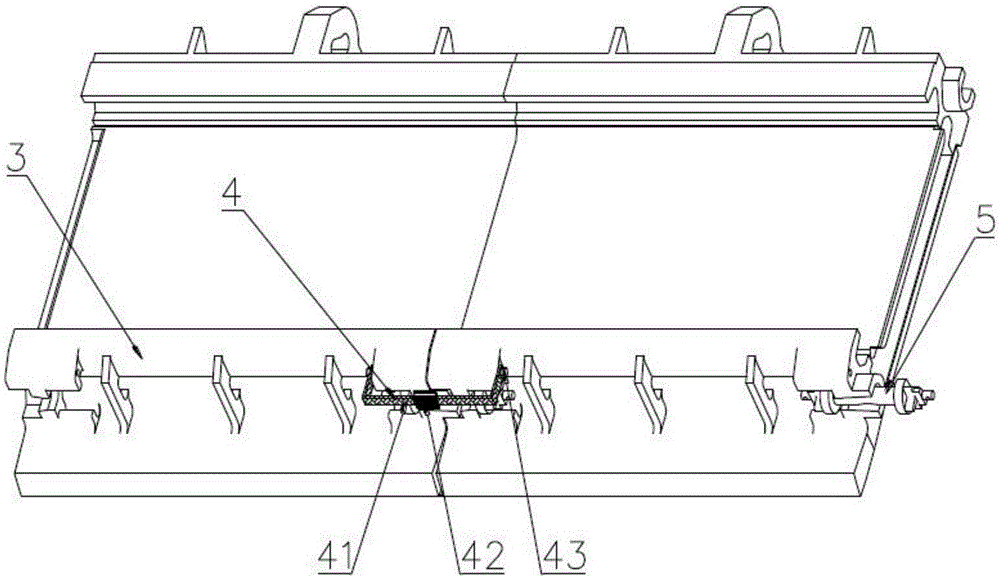

[0025] Such as Figure 4 As shown, the scraper conveyor includes a row of middle grooves 3 and a row of hydraulic supports 1 arranged side by side along the fully mechanized mining face 7. The number of the middle grooves 3 and the hydraulic supports 1 are the same and correspond to each other. The pull rod 6 is connected to the middle groove 3, and the end of the middle groove 3 is provided with a dumbbell pin 5.

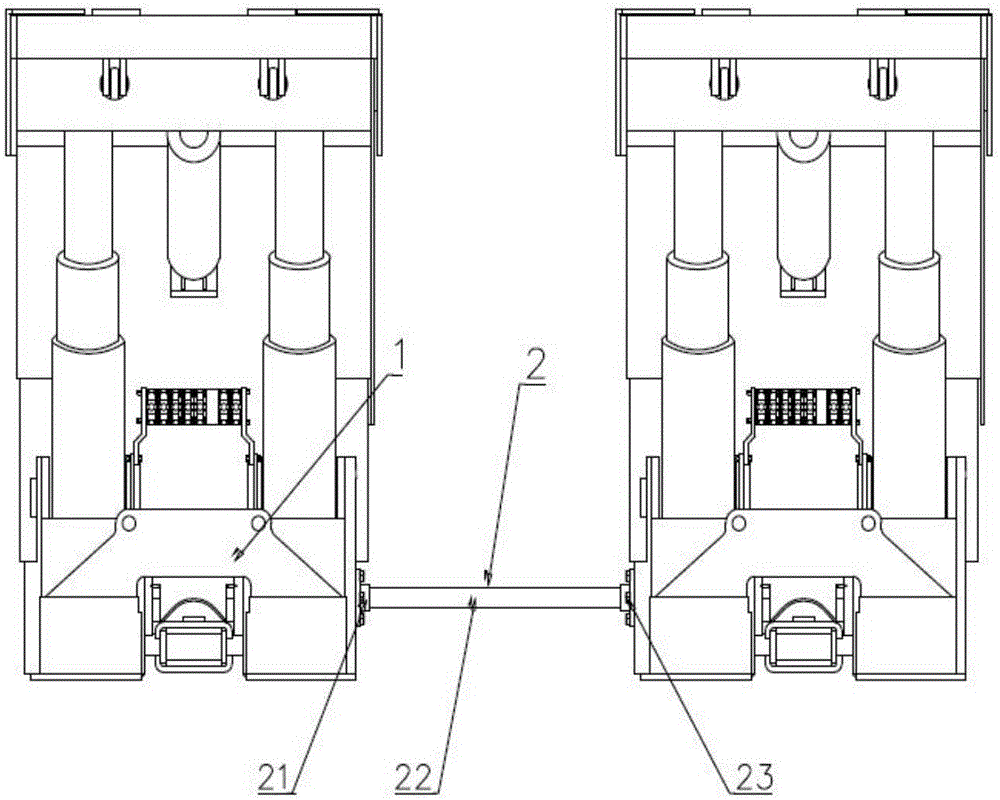

[0026] Such as figure 2 with 3 As shown, the automatic straightening device of the body of the scraper conveyor in the fully mechanized mining face of the present invention includes an elastic rod 2, a relative pose measuring device, a signal processing system, a data transmission module and an electro-hydraulic control system. The elastic rod 2 is arranged between any two adjacent hydraulic supports 1. The elastic rod 2 includes a fixed base 21, a free...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com