A co-based 2 Enriched parallel flow regenerative lime kiln production process

A production process, regenerative technology, applied in lime production, chemical instruments and methods, inorganic chemistry, etc., to achieve the effect of increasing product added value and eliminating circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

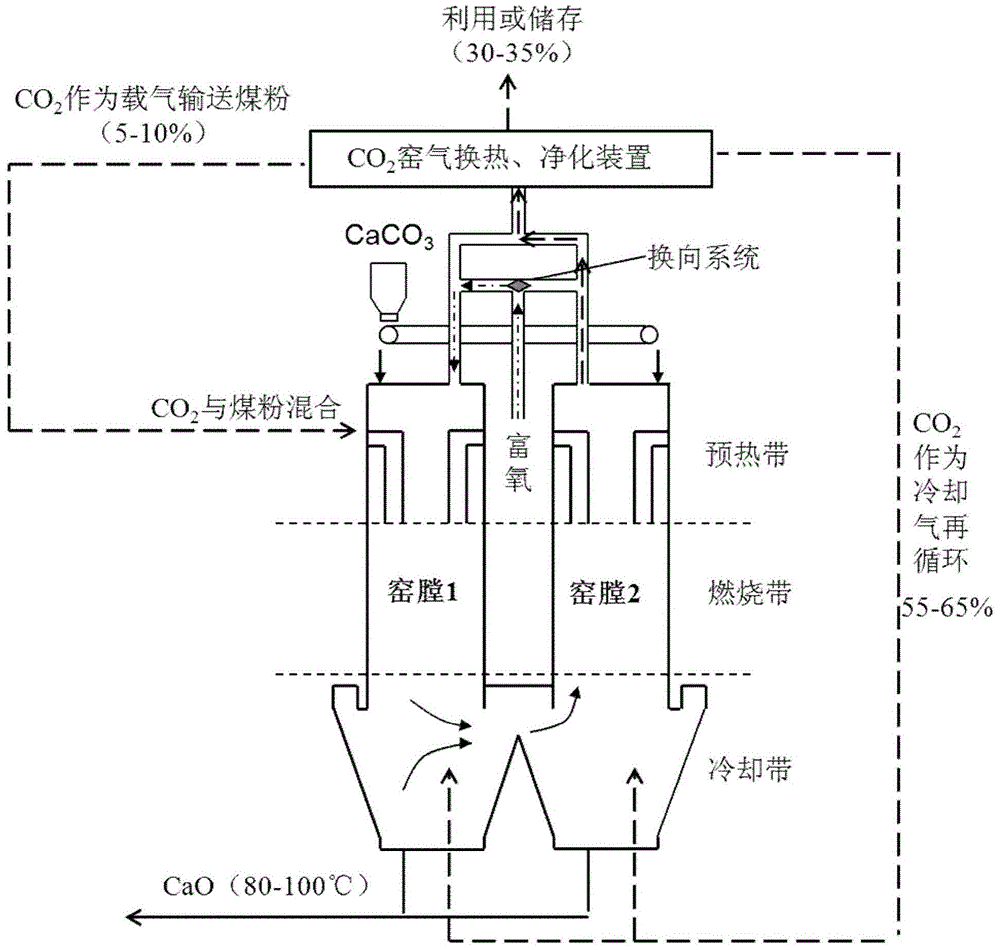

[0024] In this example, based on CO 2 The structure of enriched parallel flow regenerative lime kiln system is as follows: figure 1 As shown, the dust removal device used in the system is a bag filter, and the fuel is pulverized coal. The dust concentration of the flue gas discharged from the exhaust port is ≤50mg / Nm 3 .

[0025] The above parallel flow regenerative lime kiln system is used to produce quicklime (CaO). The daily output of quicklime is 450 tons, 80 production cycles per day, the amount of pulverized coal per production cycle is 240 kg~270kg, and the excess coefficient of combustion air is 1.1~1.4.

[0026] CO-based 2 The enriched parallel flow regenerative lime kiln production process method comprises the following steps:

[0027] (1) In the first combustion cycle, the limestone raw material is transported from the stone silo in front of the kiln to the weighing hopper, and the limestone raw material is weighed by the weighing hopper and then loaded into the...

Embodiment 2

[0040] In this example, based on CO 2 The structure of enriched parallel flow regenerative lime kiln system is as follows: figure 1 As shown, the dust removal device used in the system is a bag filter, and the fuel is pulverized coal. The dust concentration of the flue gas discharged from the exhaust port is ≤50mg / Nm 3 .

[0041] The above parallel flow regenerative lime kiln system is used to produce quicklime (CaO). The daily output of quicklime is 500 tons, 80 production cycles per day, the amount of pulverized coal per production cycle is 265kg~300kg, and the excess coefficient of combustion air is 1.1~1.4.

[0042]CO-based 2 The enriched parallel flow regenerative lime kiln production process method comprises the following steps:

[0043] (1) In the first combustion cycle, the limestone raw material is transported from the stone silo in front of the kiln to the weighing hopper, and the limestone raw material is weighed by the weighing hopper and then loaded into the f...

Embodiment 3

[0055] In this example, based on CO 2 The structure of enriched parallel flow regenerative lime kiln system is as follows: figure 1 As shown, the dust removal device used in the system is a bag filter, and the fuel is pulverized coal. The dust concentration of the flue gas discharged from the exhaust port is ≤50mg / Nm 3 .

[0056] The above parallel flow regenerative lime kiln system is used to produce quicklime (CaO). The daily output of quicklime is 550 tons, 80 production cycles per day, the amount of pulverized coal per production cycle is 290 kg ~ 330 kg, and the excess coefficient of combustion air is 1.1 ~ 1.4.

[0057] CO-based 2 The enriched parallel flow regenerative lime kiln production process method comprises the following steps:

[0058] (1) In the first combustion cycle, the limestone raw material is transported from the stone silo in front of the kiln to the weighing hopper, and the limestone raw material is weighed by the weighing hopper and then loaded int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com