H13 die steel heat treating method and H13 die steel obtained through same

A heat treatment method and die steel technology, applied in the heat treatment of H13 die steel, in the field of H13 die steel, can solve the problems of steel ingot oxidation loss, decarburization, abnormal grain growth, long residence time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

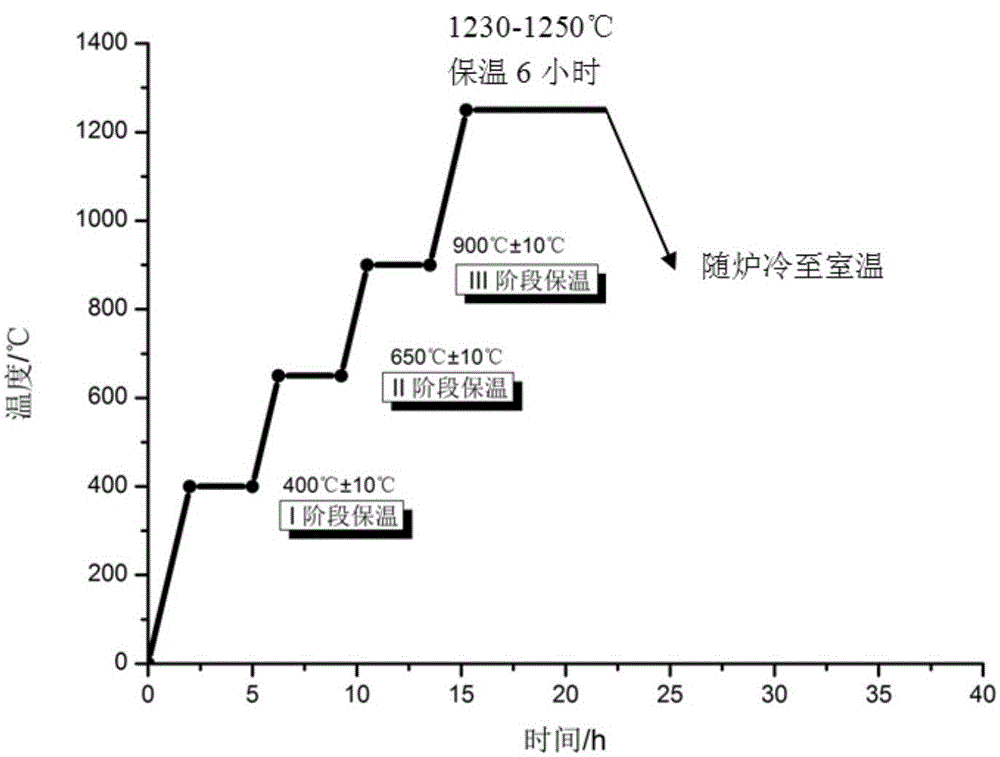

[0023] The heat treatment method of H13 mold steel, it may further comprise the steps:

[0024] Step 1. Heat forging the H13 steel ingot obtained after electroslag remelting, using two upsetting and two drawing processes, heating to 850-1180°C to break dendrites and the segregation area between dendrites, and the initial forging temperature is 1180 °C, the final forging temperature is 850 °C;

[0025] The first upsetting is to less than 50% of the height of the original steel ingot. The equipment is Lanshi Heavy Industry 3150T free forging press, and then it is stretched to 120% of the original length. After the first upsetting process, the billet is returned to the furnace for at least 3 hours;

[0026] After the second upsetting process, the billet is heated to 1240°C and held for 6 hours, and then drawn into shape. This process is completed in two times. The first day is upsetting twice, and the second day is formed. The draft ratio of more than 1.5 should be reserved for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com