Preparation method of soft partition plate for double pulse engine

An engine and double-pulse technology, applied in the direction of machines/engines, rocket engine devices, mechanical equipment, etc., can solve the problems of low pressure bearing strength, unstable opening performance, etc., and achieve the effect of product size and apparent quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for preparing a soft partition for a dual-pulse engine, comprising the following steps:

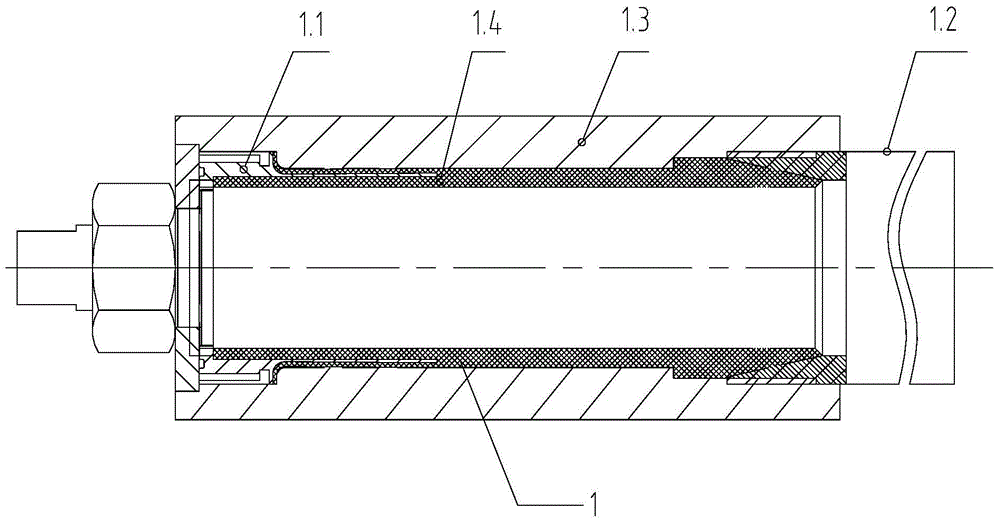

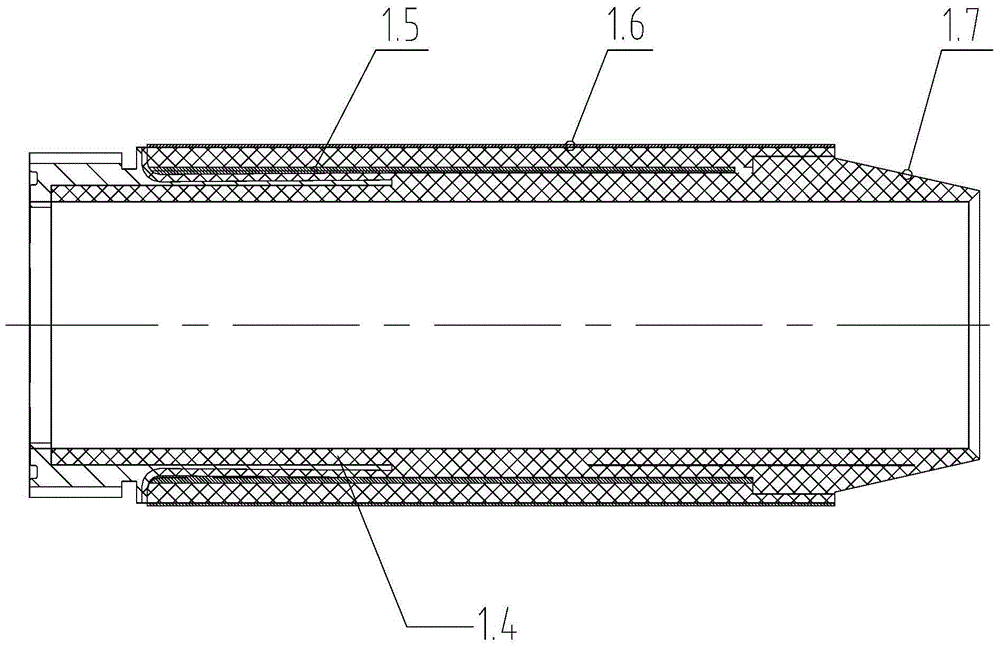

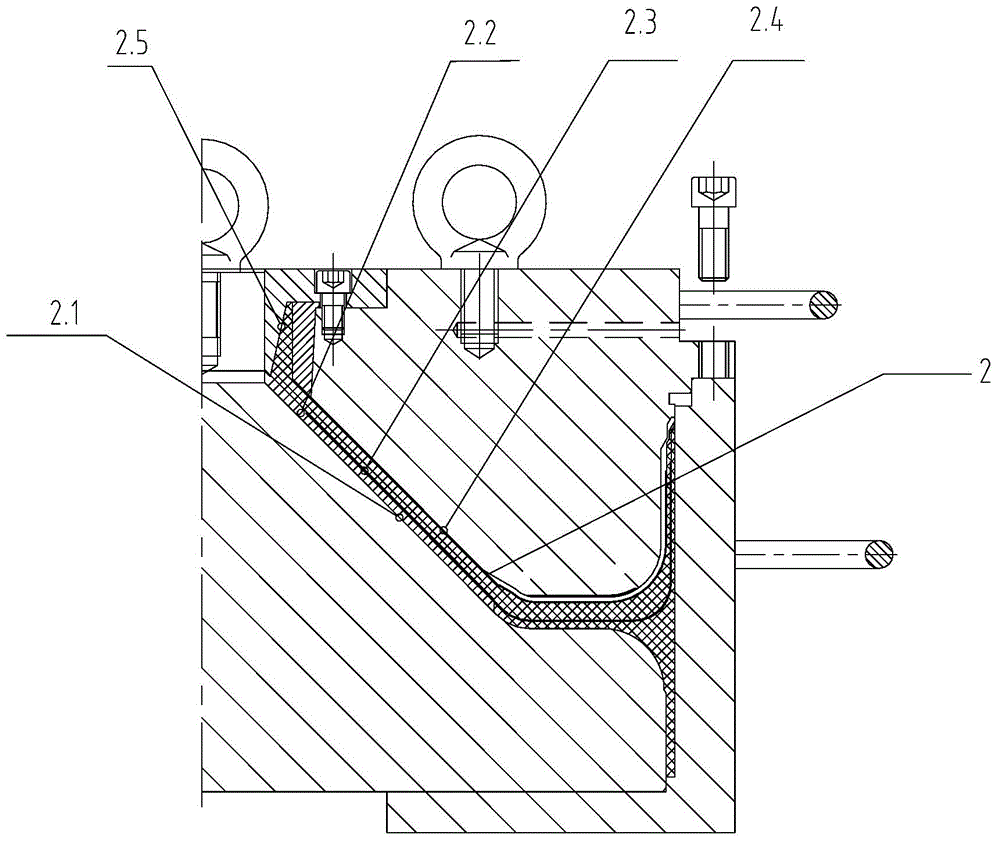

[0044] 1) According to the structural characteristics of the product, determine the molding process of the two parts of the barrel section 1 and the cone section 2, as well as the bonding method of the two parts;

[0045] 2) Prepare barrel section 1 containing metal connectors

[0046] a. Sandblast the inner and outer surfaces of the metal connector 1.1 to make the surface evenly fluffed, clean the sandblasted surface with ethyl acetate solvent, dry it, and brush the inner and outer sandblasted surface of the joint with EPDM rubber Mlock 205 or A-2 type adhesive;

[0047] Carry out manual patching of EPDM rubber on the mandrel 1.2, the thickness of the patch reaches the inner diameter of the metal connector 1.1, and then put the metal connector 1.1 on the surface of the manual patch and fit it to the positioning surface of the mandrel;

[0048] b. Continue manual patchin...

Embodiment 2

[0060] A method for preparing a soft partition for a dual-pulse engine, comprising the following steps:

[0061] 1) According to the structural characteristics of the product, determine the molding process of the two parts of the barrel section 1 and the cone section 2, as well as the bonding method of the two parts;

[0062] 2) Prepare barrel section 1 containing metal connectors

[0063] a. Sandblast the inner and outer surfaces of the metal connector 1.1 to make the surface evenly fluffed, clean the sandblasted surface with ethyl acetate solvent, dry it, and brush the inner and outer sandblasted surface of the joint with EPDM rubber Mlock 205 or A-2 type adhesive;

[0064] Carry out manual patching of EPDM rubber on the mandrel 1.2, the thickness of the patch reaches the inner diameter of the metal connector 1.1, and then put the metal connector 1.1 on the surface of the manual patch and fit it to the positioning surface of the mandrel;

[0065] b. Continue manual patchin...

Embodiment 3

[0078] A method for preparing a soft partition for a dual-pulse engine, comprising the following steps:

[0079] 1) According to the structural characteristics of the product, determine the molding process of the two parts of the barrel section 1 and the cone section 2, as well as the bonding method of the two parts;

[0080] 2) Prepare barrel section 1 containing metal connectors

[0081] a. Sandblast the inner and outer surfaces of the metal connector 1.1 to make the surface evenly fluffed, clean the sandblasted surface with ethyl acetate solvent, dry it, and brush the inner and outer sandblasted surface of the joint with EPDM rubber Mlock 205 or A-2 type adhesive;

[0082] Carry out manual patching of EPDM rubber on the mandrel 1.2, the thickness of the patch reaches the inner diameter of the metal connector 1.1, and then put the metal connector 1.1 on the surface of the manual patch and fit it to the positioning surface of the mandrel;

[0083] b. Continue manual patchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com