Grease oxidation degree fast detection method and testing box

A technology of oil oxidation and detection method, which is applied in the direction of analyzing the material through chemical reaction and material analysis through observing the influence on the chemical indicator, which can solve the problems of poor stability and repeatability, slow separation of oil layer color layer, Long color development time and other issues, to achieve the effects of reducing pollution, low use and operation costs, and conducive to on-site operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

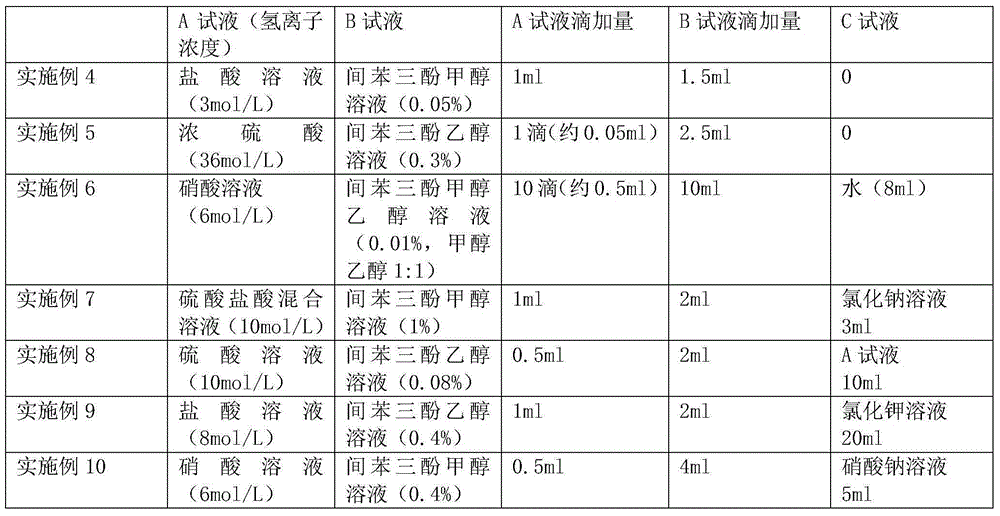

Examples

Embodiment 1

[0041] 1) Oil sample

[0042] 1# oil sample: fresh soybean oil

[0043] 2# oil sample: edible soybean oil to be tested

[0044] 3# oil sample: edible soybean oil to be tested

[0045] 4# oil sample: edible soybean oil to be tested

[0046] 2) Reagent

[0047] A test solution: concentrated hydrochloric acid (37%, about 12mol / L)

[0048] B test solution: phloroglucinol ethanol solution (0.1%)

[0049] C test solution: for A test solution

[0050] 3) Preparation of colorimetric card / colorimetric reference solution

[0051]Add a certain amount of 1,1,3,3-tetraethoxypropane to 1# oil sample to prepare MDA standard oil samples containing MDA 0, 2.5ppm, 5ppm, take 5ml of the above oil samples respectively , in the test tube, add 1.0ml of test solution A, shake for 30 times, add 5.0ml of test solution B and shake for 30 times, let stand for 10min to develop color, then add 4.0ml of test solution C (test solution A), shake Shake for 10 times and let it stand for 1 min to obtain...

Embodiment 2

[0061] 1) Oil sample

[0062] 5# oil sample: fresh peanut oil

[0063] 6# oil sample: edible peanut oil to be tested

[0064] 7# oil sample: edible peanut oil to be tested

[0065] 2) Reagent

[0066] A test solution: sulfuric acid solution (50%, about 18mol / L)

[0067] B test solution: phloroglucinol methanol solution (0.1%)

[0068] 3) Preparation of colorimetric card / colorimetric reference solution

[0069] Add a certain amount of 1,1,3,3-tetraethoxypropane to 5# oil sample to prepare MDA standard oil samples containing MDA 0, 2.5ppm, 5ppm, take 2ml of the above oil samples respectively , in a 15ml cuvette, add 20 drops of test solution A, shake for 30 times, add 3ml of test solution B and shake for 30 times, let it stand for 10 minutes to develop color, and obtain 0ppm, 2.5ppm and 5ppm of malondialdehyde respectively. The colorimetric reference solution, according to the color printing color card of supernatant solution gained color is as follows table: (color refere...

Embodiment 3

[0080] 1) Oil sample

[0081] 5# oil sample: fresh peanut oil

[0082] 6# oil sample: edible peanut oil to be tested

[0083] 7# oil sample: edible peanut oil to be tested

[0084] 2) Reagent

[0085] A test solution: sulfuric acid solution (50%, about 18mol / L)

[0086] B test solution: phloroglucinol methanol solution (0.1%)

[0087] C test solution: water

[0088] 3) Preparation of colorimetric card / colorimetric reference solution

[0089] Add a certain amount of 1,1,3,3-tetraethoxypropane to 5# oil sample to prepare MDA standard oil samples containing MDA 0, 2.5ppm, 5ppm, take 2ml of the above oil samples respectively , in a 15ml cuvette, add 20 drops of test solution A, shake for 30 times, add 3ml of test solution B and shake for 30 times, let stand for 10min to develop color, then add 2ml of test solution C, shake for 10 times, Leave standstill 1min, obtain respectively the colorimetric reference solution that contains malondialdehyde 0ppm, 2.5ppm, 5ppm, print the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com