Magnetic control submerged-arc welding seam tracking signal analyzing method based on experience wavelet transformation

An empirical wavelet and submerged arc welding technology, applied in spectrum analysis, arc welding equipment, welding equipment, etc., can solve problems such as mode mixing, unreasonable convergence conditions of EMD decomposition, and difficulty in filtering out weld seam tracking signal interference signals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with accompanying drawings and embodiments, but the present invention is not limited.

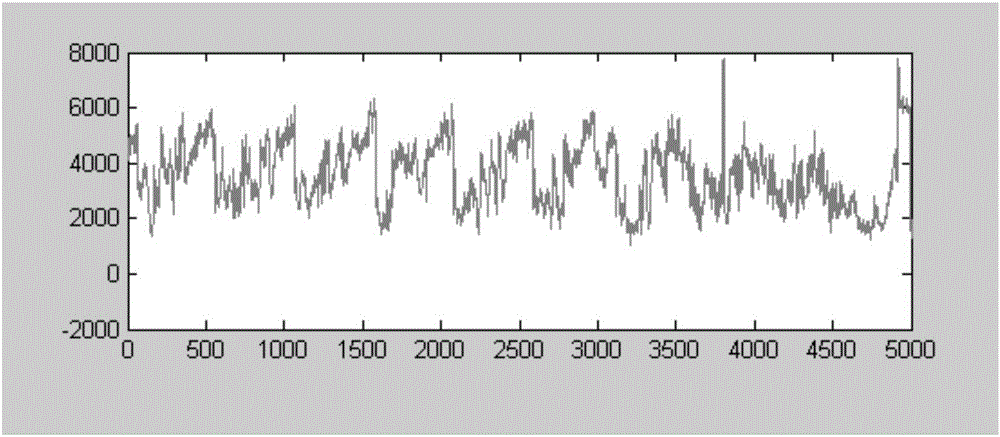

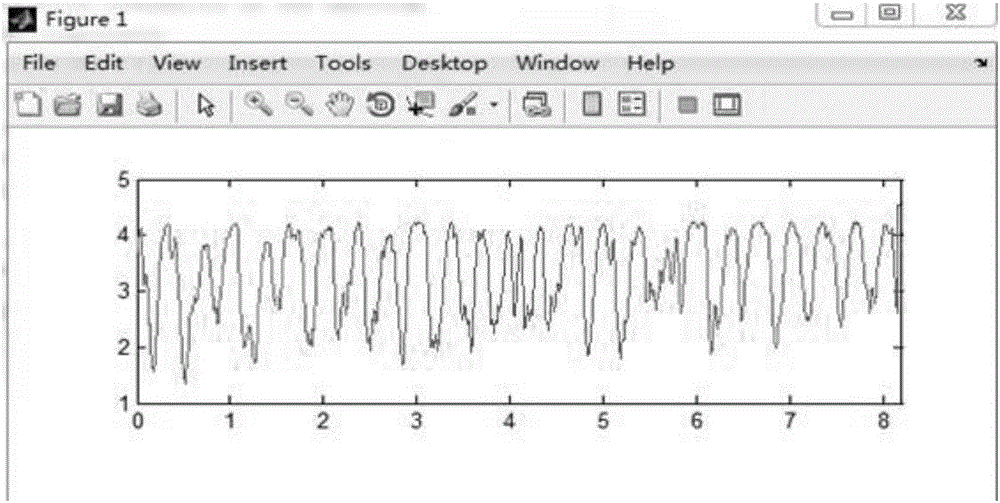

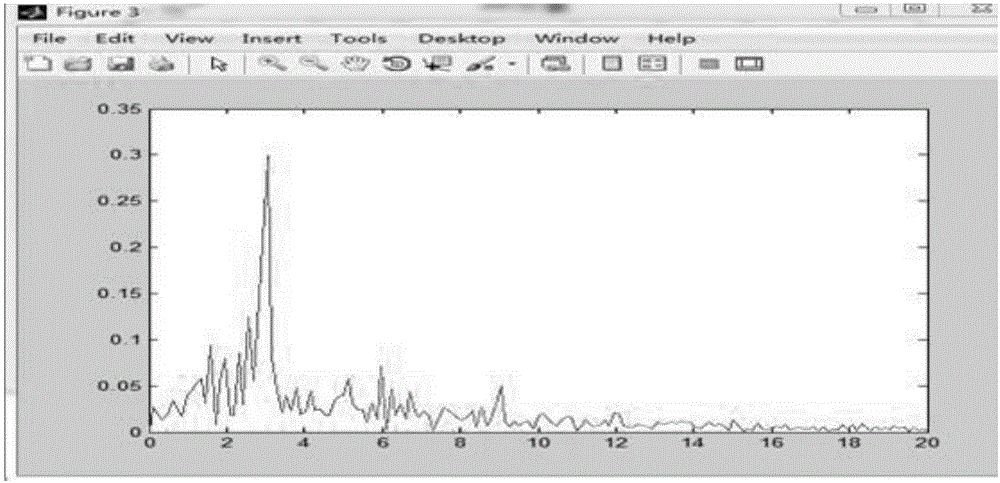

[0017] 1. First, the magnetron submerged arc welding seam tracking sensor controls the arc swing to scan the weld groove, and the Hall sensor collects the original signal such as figure 1 , and then perform hardware filtering on the primary sampling signal of the magnetron submerged arc welding seam tracking arc. The sampling signal is as follows figure 2 As shown, it is the voltage signal collected by the virtual oscilloscope Dso2904_512 after hardware filtering. image 3 It is the spectrum analysis diagram of the sampled signal after hardware filtering.

[0018] Secondly, the empirical wavelet transform signal analysis method is used to analyze the low-frequency signal of the tracking signal after hardware filtering, and a group of wavelet filter banks are adaptively selected according to the Fourier s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com