Transverse IV-clan element quantum well photoelectric detector and preparation method

A photodetector and quantum well technology, applied in the field of photodetectors, can solve the problems of GeSn difficulty, material quality and thermal stability deterioration, difficulty in wide-ranging band gap adjustment, etc., to improve the band gap adjustment effect and price of materials. Inexpensive, Enhanced Effect of Bandgap Tuning Effect of Materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

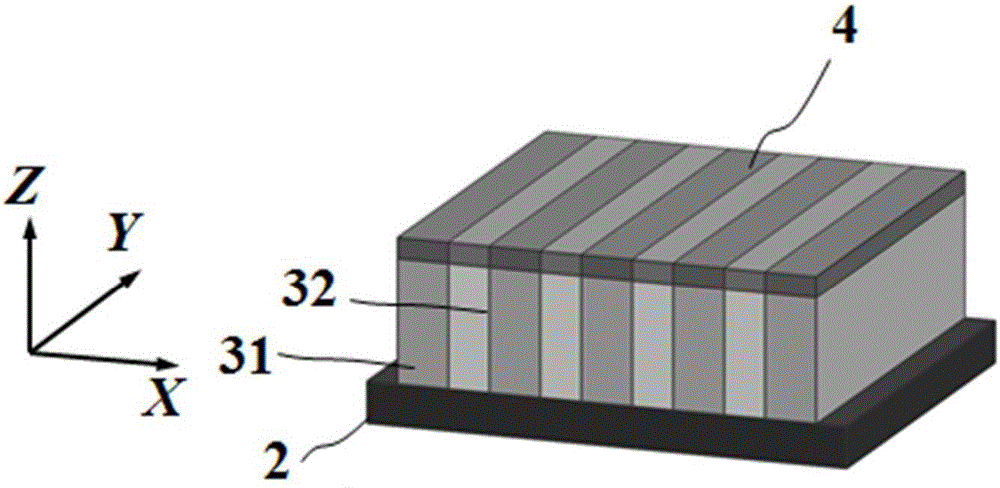

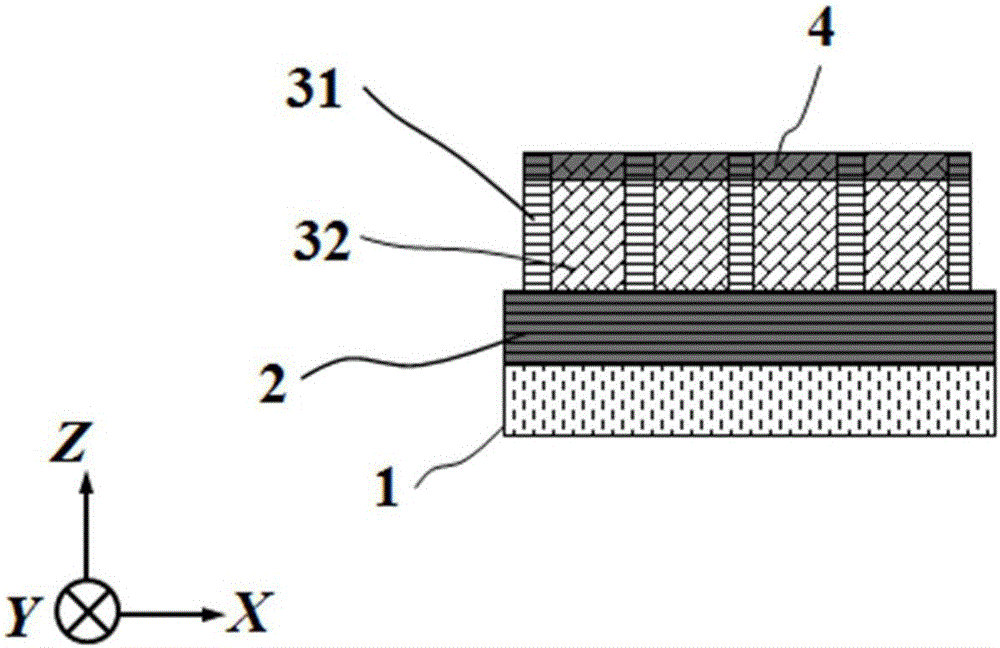

[0028] Embodiment 1: Fabricate a lateral group IV element quantum well photodetector with the Sn composition of the quantum well being 0.3, the Ge composition of the potential barrier layer being 0, and the Si composition being 0.7.

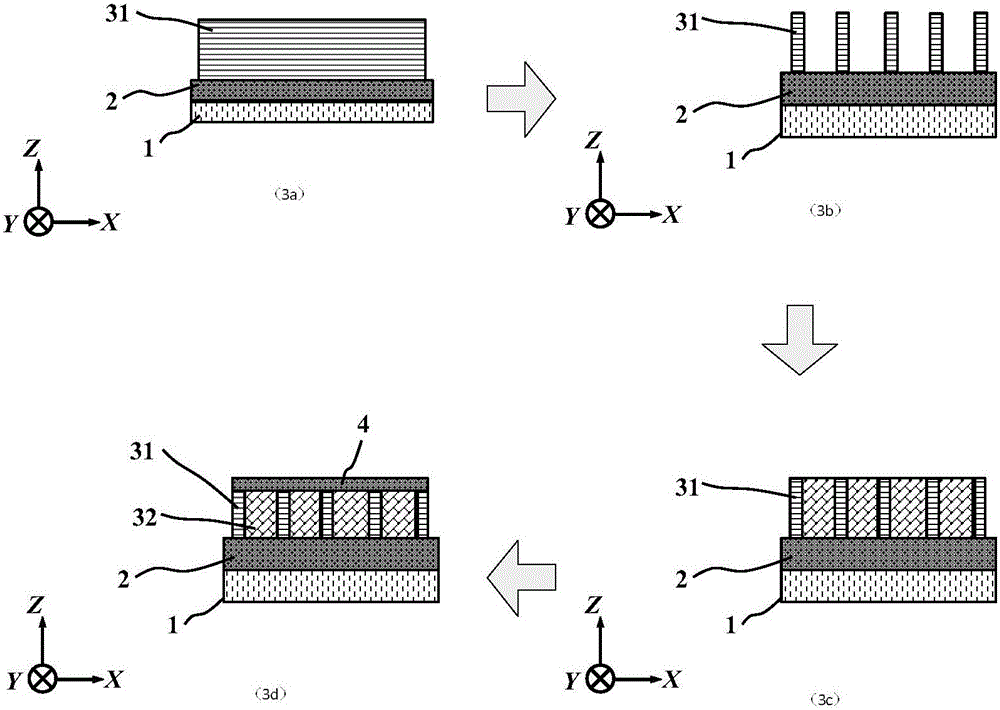

[0029] Step 1: On Si substrate 1, utilize molecular beam epitaxy process, use solid phosphorus, germanium and tin as evaporation source, use 10 -4 Pa pressure, in the environment of 180 ℃, grow n-type GeSn single crystal and relaxed intrinsic GeSn single crystal sequentially, in which the Sn composition is 0.3, and the Ge composition is 0.7. The grown n-type GeSn single crystal is Lower electrode 2, such as image 3 a.

[0030] Step 2: Etching the intrinsic GeSn single crystal into a lateral quantum well 31 under the masking effect of the photoresist by using the chloride-based ion group, such as image 3 b.

[0031] Step 3: using molecular beam epitaxy, using solid silicon, germanium and tin as evaporation sources, using 10 -4 Pa pressure, u...

Embodiment 2

[0034]Embodiment 2: Fabricate a lateral group IV element quantum well photodetector with the Sn composition of the quantum well being 0.15, the Ge composition of the potential barrier layer being 0.5, and the Si composition being 0.35.

[0035] Step 1: Sequential epitaxial relaxation of n-type GeSn single crystal and intrinsic GeSn single crystal

[0036] On the SOI substrate 1, with solid phosphorus, germanium and tin as evaporation sources, at a temperature of 190°C and a pressure of 10 -4 Pa environment, the epitaxial Sn composition is 0.15, the Ge composition is 0.85 n-type GeSn single crystal and the relaxation intrinsic GeSn single crystal, such as image 3 a.

[0037] Step 2: Etching quantum wells

[0038] Using chlorine-based ion groups as an etchant, under the masking effect of photoresist, longitudinally etch the relaxed intrinsic GeSn single crystal in step 1 epitaxy to form a quantum well 2 of GeSn single crystal material, such as image 3 b.

[0039] Step 3: E...

Embodiment 3

[0044] Embodiment 3: Fabricate a lateral group IV element quantum well photodetector in which the Sn composition of the quantum well is 0, the Ge composition of the potential barrier layer is 1, and the Si composition is 0.

[0045] Step A: using molecular beam epitaxy on a Ge substrate 1, using solid phosphorus, germanium and tin as evaporation sources, at a temperature of 200°C and a pressure of 10 -4 Pa environment, sequentially epitaxial n-type GeSn single crystal with Sn composition 0, Ge composition 1 and relaxed intrinsic GeSn single crystal, such as image 3 a.

[0046] Step B: Using chloride-based ion groups as etchant, under the masking effect of photoresist, etch intrinsic GeSn single crystal into lateral quantum wells, such as image 3 b.

[0047] Step C: Using molecular beam epitaxy, grow a SiGeSn single crystal material with a Si composition of 0, a Ge composition of 1, and a Sn composition of 0 in the gap between GeSn quantum wells, such as image 3 c. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com