Magnesium alloy storage battery

A storage battery, magnesium alloy technology, applied in the direction of alkaline storage battery, alkaline storage battery manufacturing, battery electrodes, etc., can solve the problems of inability to carry around, damage the environment, pollute the water and soil environment, etc., and achieve weight reduction and long storage time. , the effect of saving money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

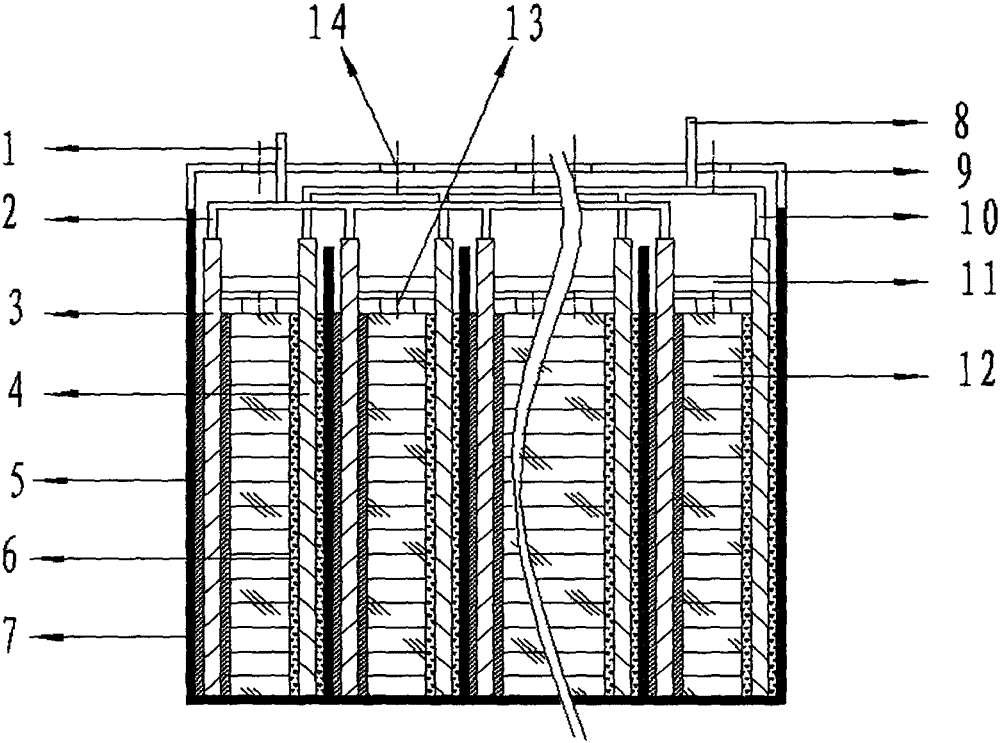

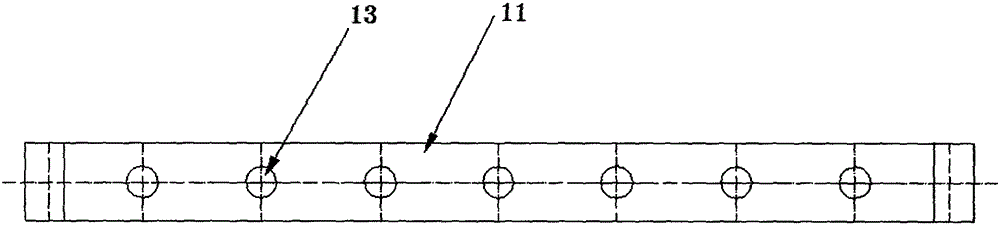

[0015] refer to figure 1 and figure 2 , a magnesium alloy accumulator of the present invention, comprises battery shell 7, interlayer 11 and loam cake 9, loam cake 9 and battery shell 7 match, loam cake 9 is provided with water injection hole 14; Battery shell 7 is separated into Several reaction chambers, the positive electrode of the battery in each reaction chamber is a tinplate sheet 3, and the surface is covered with a conductive electrode film 5; the negative electrode of the battery is a magnesium plate 4, and the surface is covered with glass fiber separator paper 6, and the space between the positive and negative electrodes of the battery 12 Fill and compact with positive electrode powder, positive electrode powder is made of MnO 2 , acetylene black, flake graphite, and NaCl, the weight ratio is 85:7.5:7.5:15; each reaction chamber is covered with a partition 11, and the partition 11 is provided with a water inlet 13; each The positive poles of the batteries in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com