Manufacturing method of superconducting conductor and superconducting conductor

A manufacturing method and technology of superconducting conductors, applied in the usage of superconducting elements, cable/conductor manufacturing, superconducting/high-conducting conductors, etc., to achieve the effect of good superconducting properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

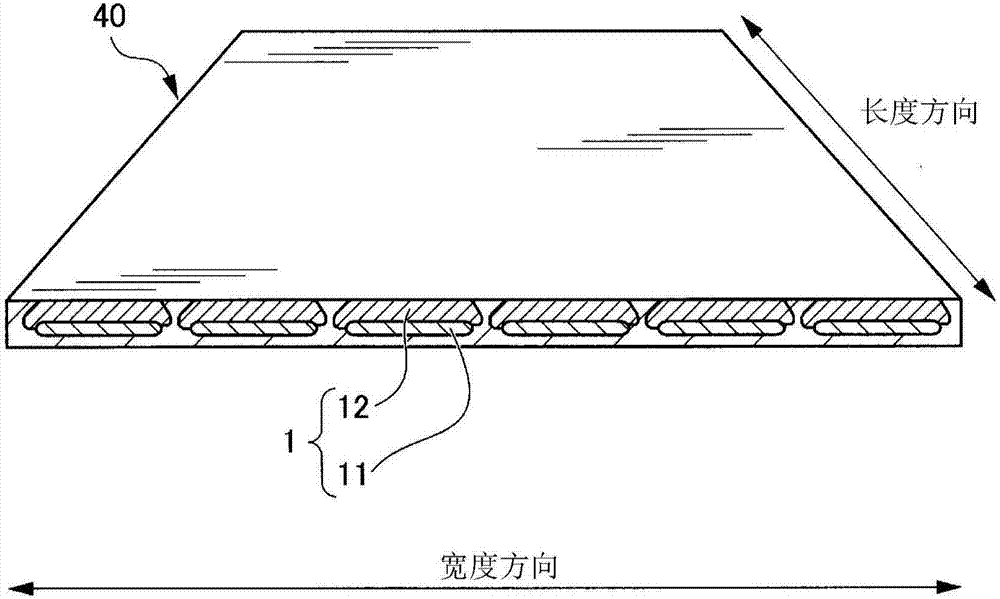

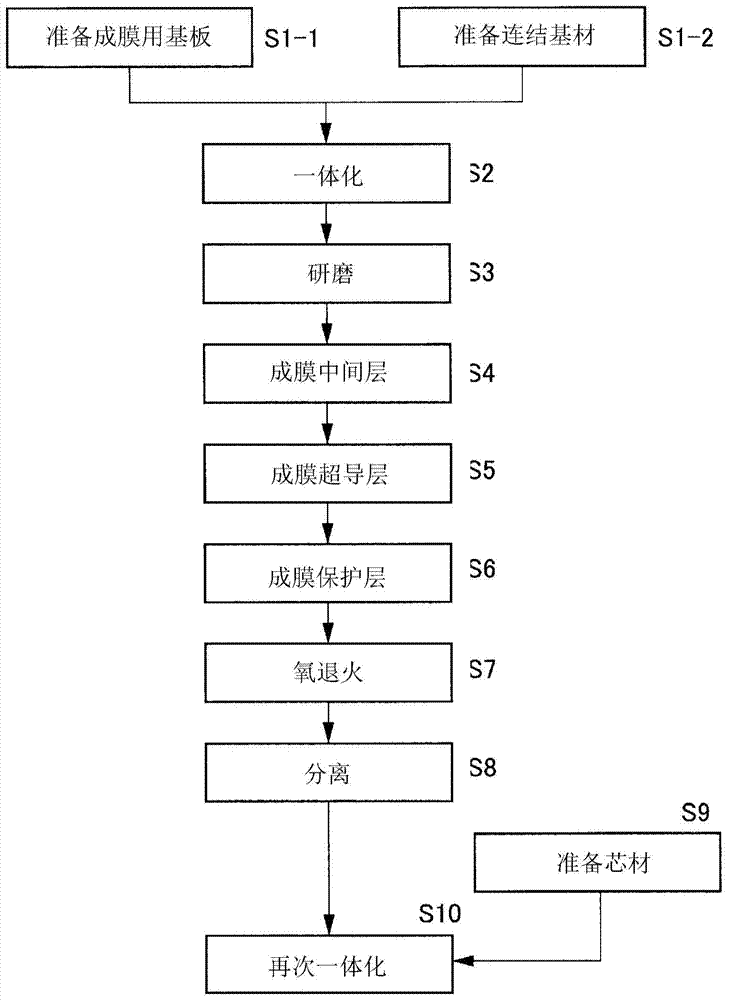

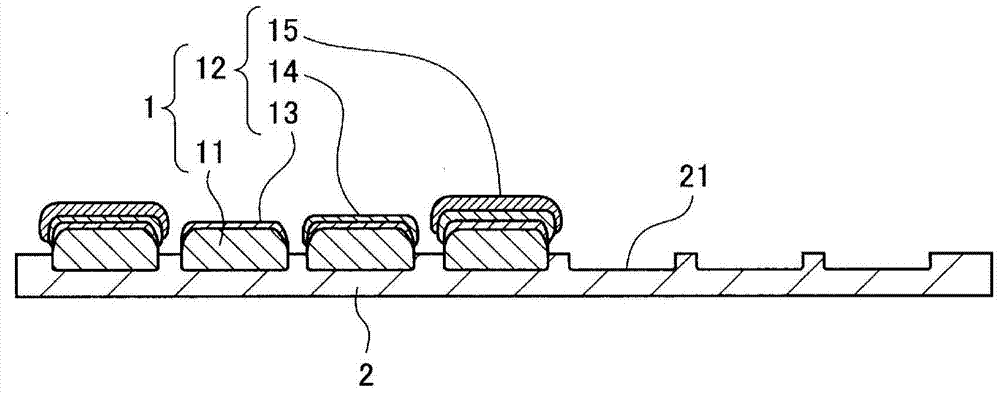

[0030] As a first embodiment of the present invention, a method in which a plurality of narrow film-forming substrates are embedded in a joint base material to be integrated, and an intermediate layer, a superconducting layer, After performing oxygen annealing on the protective layer, the superconducting wires are produced in units of film-forming substrates by separating them from the connecting substrates, and the obtained superconducting wires are wound around the outer circumference of the circular core wires and again Integrate to produce a circular composite superconducting conductor. figure 1 It is a flowchart of the main process.

[0031]

[0032] Form the wire to the specified cross-sectional dimensions. The metal used is preferably a material having a Vickers hardness (Hv hardness: VIckers-hardness) greater than 100, and alloys containing Cu, Ni, Ti, Mo, Nb, Ta, W, Fe, and Ag can be used. Particularly preferred are stainless steel, Hastelloy (registered trademark...

Embodiment 1

[0089] Examples 1 to 4 according to the above-mentioned first embodiment will be described.

[0090] (Example 1)

[0091] In Example 1, a plurality of superconducting wires having a narrow film-forming substrate having a thickness of t0.05 mm x a width of w1.0 mm produced through the steps described in the first embodiment were produced, and the obtained superconducting wires were used. The wire yields a circular composite superconducting conductor.

[0092]

[0093] will diameter The metal wire (round wire) of Hastelloy C276 was formed into a shape of thickness t0.05mm×width w1.0mm×length L1050m at a processing rate of about 34%.

[0094]

[0095] Ten grooves of depth d0.03mm×width w1.0mm are formed in parallel at a pitch of 2.5mm in the width direction over the entire length of the Hastelloy C276 alloy bar of t0.15mm×w26.5mm×L105m, and become Connect the substrate.

[0096]

[0097] The narrow film-forming substrate was inserted into ten grooves formed in the join...

Embodiment 2

[0120] In Example 2, a plurality of superconducting wires having a narrow film-forming substrate having a thickness t0.1 mm×width w2.00 mm were produced through the steps described in the first embodiment. Here, only steps S1-1, S1-2 and S2 will be described. The other steps (S3 to S8) are omitted because they are the same as those in Example 1.

[0121]

[0122] will diameter The metal wire (round wire) of Hastelloy C276 was formed into a shape of thickness t0.1mm×width w2.0mm×length L740m at a processing rate of about 34%.

[0123]

[0124] Seven grooves of depth d0.08mm x width w2.0mm are formed in parallel at a pitch of 3.5mm in the width direction over the entire length of the Hastelloy C276 alloy bar of thickness t0.2mm x width w26.5mm x length L105m , and become the connecting substrate.

[0125]

[0126] The narrow film-forming substrate was inserted into seven grooves formed in the joint base material, and the narrow film-forming substrate and the joint base...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com