Method for preparing cigarette-used smoked plum extract

A technology of sour plum and extract, which is applied in the field of preparation of sour plum extract for cigarettes, can solve the problems of ultrafiltration application limitation, concentration polarization, and permeability decrease, and achieve the purpose of avoiding heat damage, flammability, and flammability. Volatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

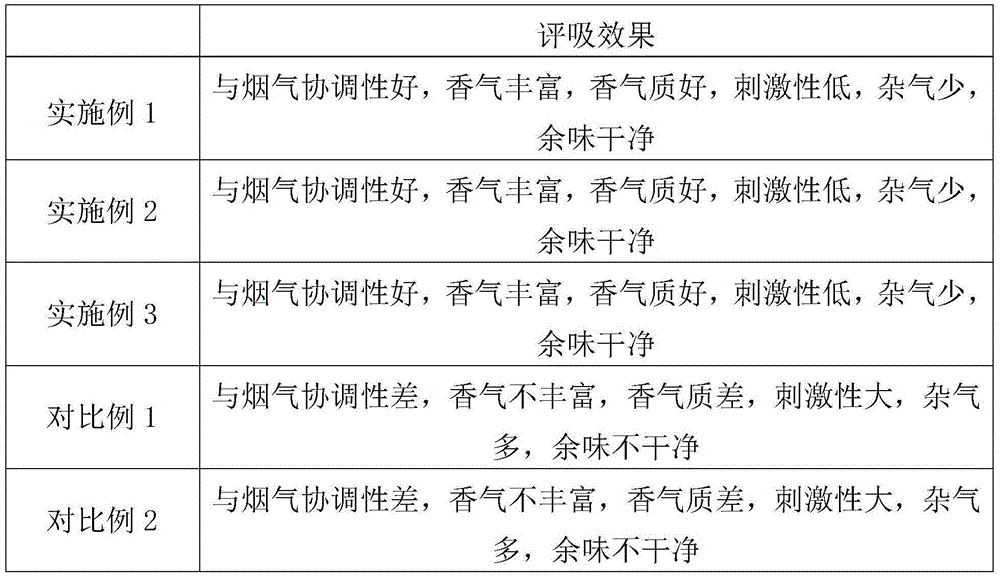

Examples

Embodiment 1

[0027] A preparation method for smoked sour plum extract, which comprises the following steps:

[0028] (1) Ultrasonic countercurrent extraction: clean the fresh sour plums, add 8 times of 60% ethanol by weight to the sour plums, soak for 2 hours at a temperature of 40°C, and then perform ultrasonic countercurrent extraction. The ultrasonic frequency is 60KHz, the temperature is 40°C, and the extraction time is 60min;

[0029] (2) Alcohol precipitation: filter the obtained extract, collect the filtrate and concentrate under reduced pressure to form an extract with a relative density of 1.2, then add 4 times of 95% ethanol by weight to the extract, fully stir and let stand for 10 hours;

[0030] (3) Membrane separation: take the supernatant after alcohol precipitation, and centrifuge at 6000 rpm to remove insoluble impurities. The centrifugate is first filtered with a ceramic microfiltration membrane with a pore size of 0.45 μm, and then 0.06% by weight is added to the filtrate...

Embodiment 2

[0033] A preparation method for smoked sour plum extract, which comprises the following steps:

[0034] (1) Ultrasonic countercurrent extraction: clean the fresh sour plums, add 5 times of 80% ethanol by weight to the sour plums, soak for 3 hours at a temperature of 30°C, and then perform ultrasonic countercurrent extraction. The ultrasonic frequency is 50KHz, the temperature is 50°C, and the extraction time is 30min;

[0035] (2) Alcohol precipitation: filter the obtained extract, collect the filtrate and concentrate under reduced pressure to form an extract with a relative density of 1.15, then add 3 times of 95% ethanol by weight to the extract, fully stir and let stand for 8 hours;

[0036] (3) Membrane separation: take the supernatant after alcohol precipitation, and centrifuge at a high speed of 5000 rpm to remove insoluble impurities. The centrifugate is first filtered with a ceramic microfiltration membrane with a pore size of 0.22 μm, and then 0.05% by weight is added...

Embodiment 3

[0039] A preparation method for smoked sour plum extract, which comprises the following steps:

[0040] (1) Ultrasonic countercurrent extraction: clean the fresh sour plums, add 10 times of 50% ethanol by weight to the sour plums, soak for 1 hour at a temperature of 50°C, and then perform ultrasonic countercurrent extraction. The ultrasonic frequency is 100KHz, the temperature is 30°C, and the extraction time is 90min;

[0041] (2) Alcohol precipitation: filter the obtained extract, collect the filtrate and concentrate under reduced pressure to form an extract with a relative density of 1.25, then add 5 times of 85% ethanol by weight to the extract, fully stir and let stand for 12 hours;

[0042] (3) Membrane separation: take the supernatant after alcohol precipitation, 10000 rpm high-speed centrifugation to remove insoluble impurities, first filter the centrifugate with a ceramic microfiltration membrane with a pore size of 1.5 μm, and then add 0.1% by weight to the filtrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com