Chinese buckeye seed decoction piece preparation method

A technology for salvia seeds and decoction pieces, which is applied in the field of preparation of decoction pieces of sorghum seeds, can solve the problems of harsh conditions of parameters such as temperature and time, loss of aescin A, poor quality reproducibility, etc. Peeling, mild lactic acid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method of Salozi decoction pieces includes the following steps:

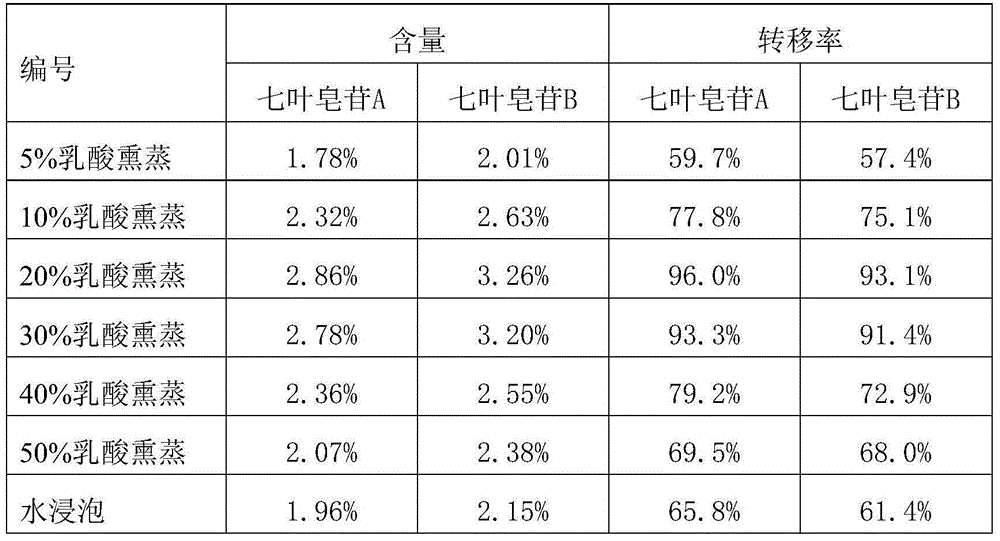

[0023] 1) Put the fresh medicinal materials of Salo seed in a pressure cooker, fumigate with a lactic acid aqueous solution with a mass concentration of 20% for 3 hours, and the fumigation temperature is 130°C;

[0024] 2) Take out the fumigated medicinal materials, let it cool, peel off the shell, and cut the pulp into thin slices with a thickness of 0.5 to 1.0 cm;

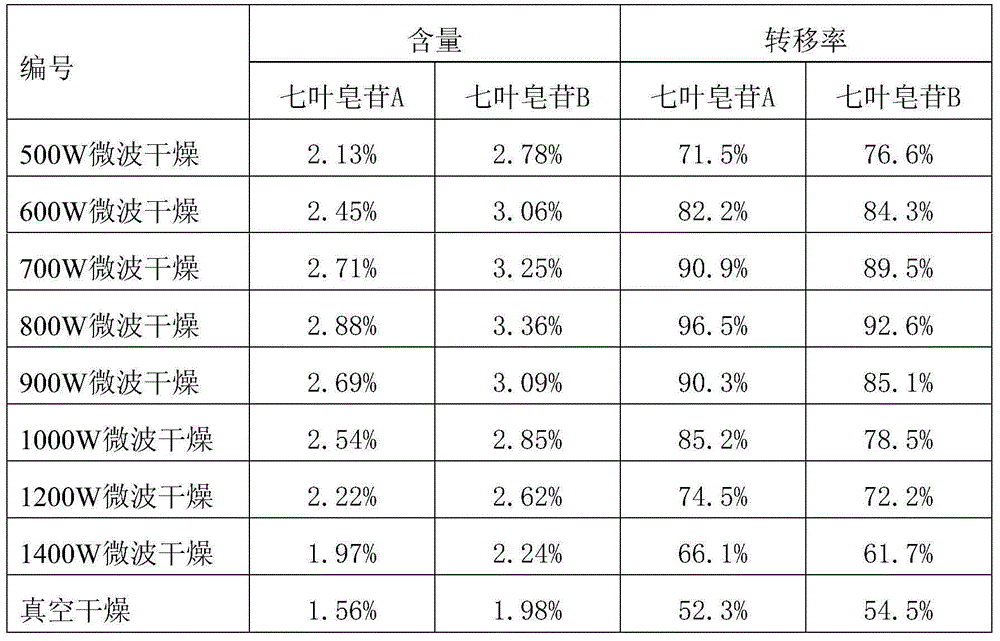

[0025] 3) Microwave drying the flakes, the microwave power is 800W, the drying time is 40 minutes, and the moisture content is 8%;

[0026] 4) The dried flakes are sterilized by ultraviolet to obtain Salozi decoction pieces.

Embodiment 2

[0028] A preparation method of Salozi decoction pieces includes the following steps:

[0029] 1) Put the fresh medicinal materials of Salozi in a pressure-resistant container, fumigate with a 30% mass concentration of lactic acid aqueous solution for 4 hours, and the fumigation temperature is 125℃;

[0030] 2) Take out the fumigated medicinal materials, let it cool, peel off the shell, and cut the pulp into thin slices with a thickness of 0.5 to 1.0 cm;

[0031] 3) Microwave drying the flakes, the microwave power is 900W, the drying time is 30 minutes, and the moisture content is 10%;

[0032] 4) The dried flakes are sterilized by ultraviolet to obtain Salozi decoction pieces.

Embodiment 3

[0034] A preparation method of Salozi decoction pieces includes the following steps:

[0035] 1) Place the fresh medicinal materials of Salo seeds in a pressure-resistant container, fumigate with a 10% mass concentration of lactic acid aqueous solution for 5 hours, and the fumigation temperature is 120°C;

[0036] 2) Take out the fumigated medicinal materials, let it cool, peel off the shell, and cut the pulp into thin slices with a thickness of 0.5 to 1.0 cm;

[0037] 3) Microwave drying the flakes, the microwave power is 600W, the drying time is 60 minutes, and the moisture content is 5%;

[0038] 4) The dried flakes are sterilized by ultraviolet to obtain Salozi decoction pieces.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Microwave power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com