Continuous esterification micro-reaction apparatus and micro-reaction system composed of same

A micro-reaction device and micro-reaction technology, applied in the field of micro-reaction systems, can solve problems such as limiting the application range of reactors, increasing costs, and technical difficulties, and achieve the effects of increasing productivity, reducing requirements, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

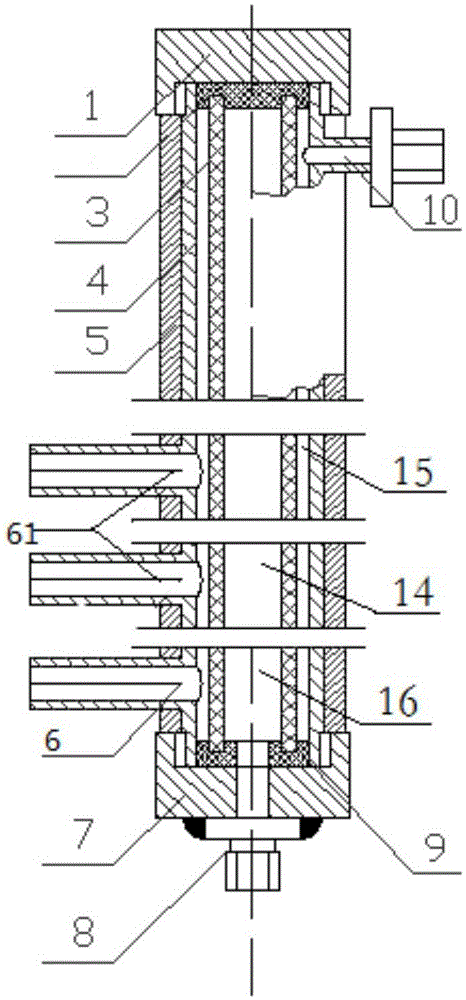

[0021] like figure 1 Shown, the continuous esterification micro-reaction device main body of embodiment 1 is added the first capping 1 and the second capping 8 that two ends seal shell by a tubular shell (4) and form an airtight in shell 4 inside. The reaction chamber 15. In this embodiment, in order to achieve a better sealing and fixing effect, a first port seal 2 is also provided at the joint between the first cover 1 and the tube case 4, and a first port seal 2 is also provided at the joint between the second cover 8 and the tube case 4. A second port seal 9 is provided. In this embodiment, the water-permeable membrane 3 is tubular, and the two ends of the tubular water-permeable membrane 3 are respectively joined to the first sealing member 2 and the second sealing member 9, thereby separating the sealed reaction chamber 15 into tubular water-permeable A first part of the reaction chamber 15 between the membrane 3 and the shell 4 and a second part of the reaction chambe...

Embodiment 2

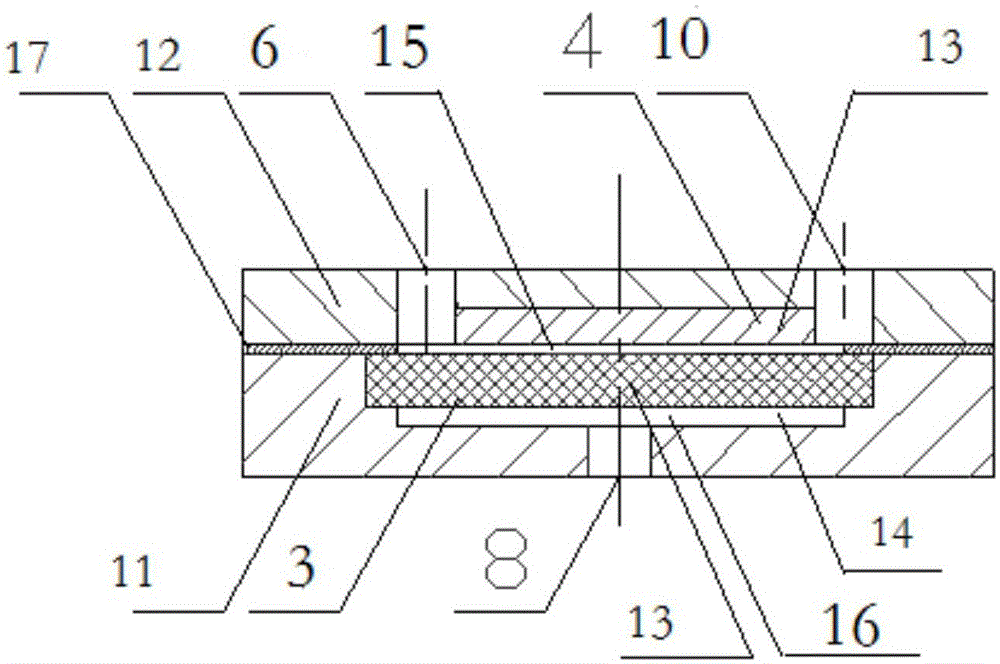

[0023] like figure 2 As shown, the continuous esterification micro-reaction device of embodiment 2 comprises upper sealing plate 12 and lower sealing plate 11, and in the present embodiment, the opposite side of upper sealing plate 12 and lower sealing plate 11 is provided with reaction tank 13, and lower sealing The opposite side of the plate 11 and the upper sealing plate 12 is provided with a reaction tank 13, the upper sealing plate 12 is relatively attached to the lower sealing plate 11, the upper sealing plate 12 and the lower sealing plate 11 are relatively tightly attached, and the upper sealing plate 12 Combined with the reaction tank 13 provided on the lower sealing plate 11 to form an airtight reaction chamber 14, a water-permeable membrane 3 is arranged in the reaction chamber 14 along a direction parallel to the lower sealing plate 11, and the water-permeable membrane 3 seals the reaction chamber 14 It is divided into a first part of the reaction chamber 15 and a...

Embodiment 3

[0025] The continuous micro-reaction system composed of the continuous esterification micro-reaction device of Example 1, the raw material inlet and the product outlet of the three continuous esterification micro-reaction devices are sequentially connected in series to form a continuous micro-reaction system.

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative humidity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| esterification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com