Near net-shape rotary swaging manufacturing method for wheel rim

A manufacturing method and rim technology are applied in the field of close-shaped forging and spinning manufacturing of rims, which can solve the problems of difficult forming of large-sized rims, poor rim precision, and difficulty in forming, and achieve a high degree of material autonomy and reduce inventory. , the effect of improving the structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

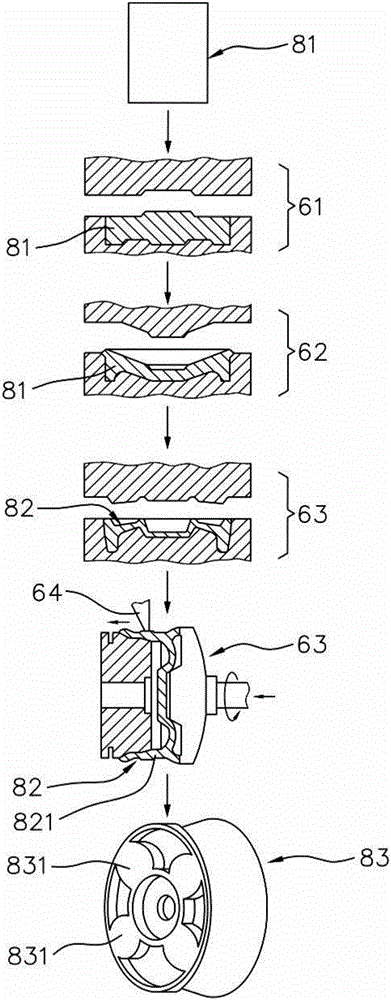

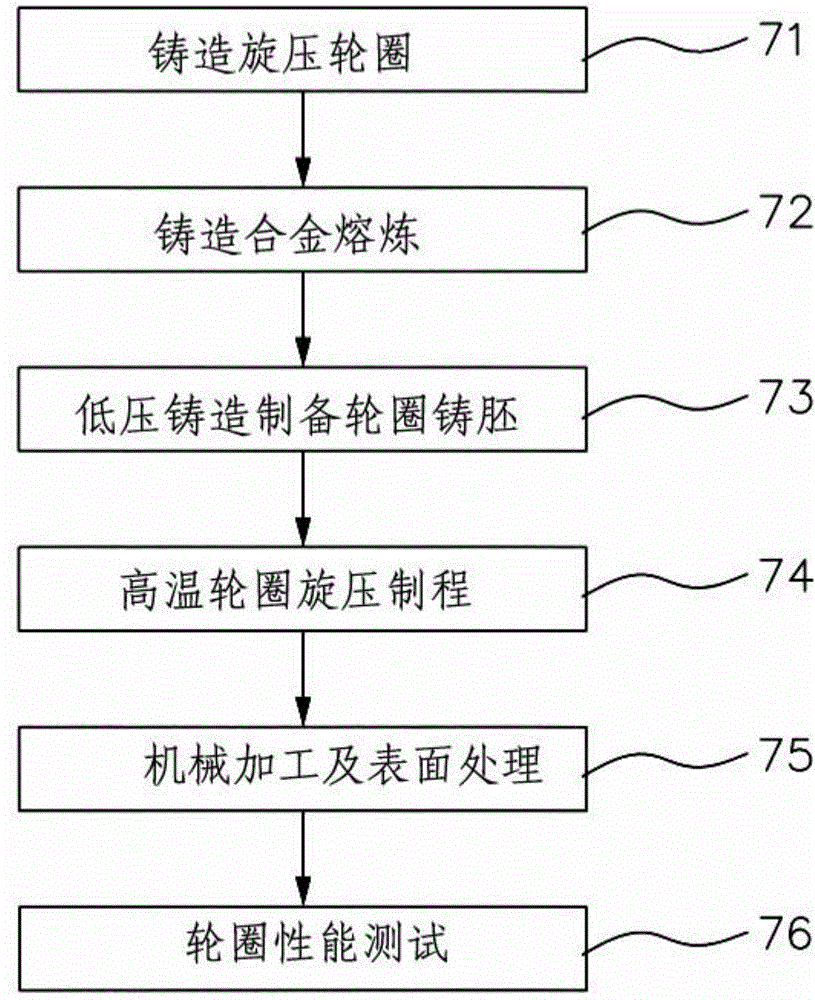

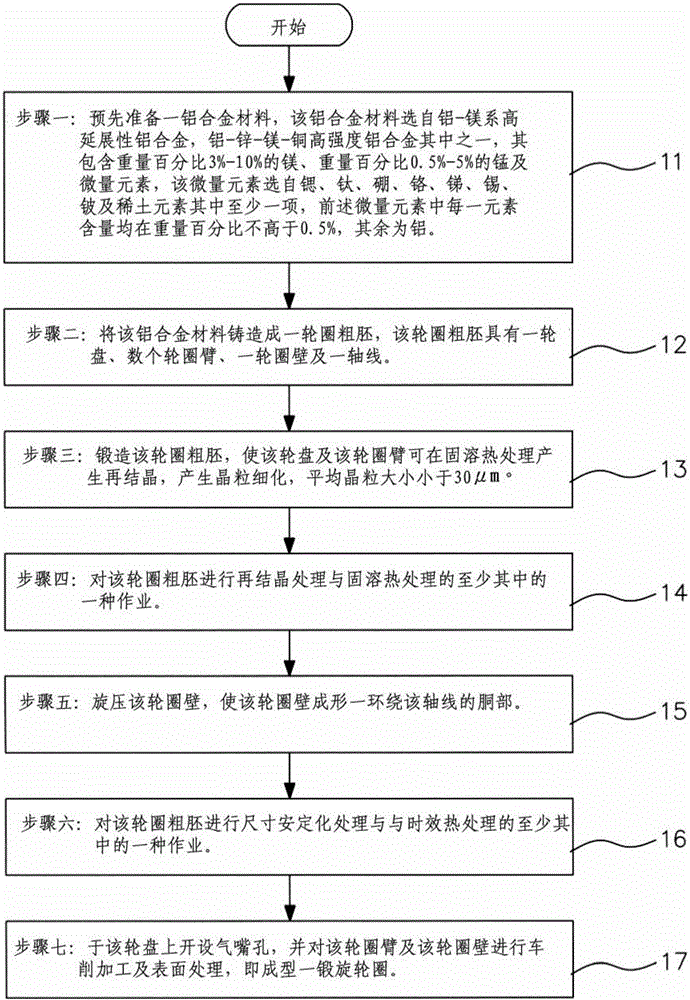

[0051] refer to image 3 , the present invention is a near-shape forging and spinning manufacturing method of a wheel rim, and its manufacturing process includes the following steps:

[0052]Step 111: Prepare an aluminum alloy material in advance, the aluminum alloy material is selected from one of aluminum-magnesium high-ductility aluminum alloys and aluminum-zinc-magnesium-copper high-strength aluminum alloys, which contains 3%-10% by weight % of magnesium (Mg), 0.5% to 5% by weight of manganese (Mn) and trace elements, the trace elements are selected from strontium (Sr), titanium (Ti), boron (B), chromium (Cr), antimony ( At least one of Sb), tin (Sn), beryllium (Be) and rare earth elements (RE), the content of each element in the aforementioned trace elements is in weight percentage

[0053] Not more than 0.5%, the rest is aluminum (A1);

[0054] Step 2 12: Refer to Figure 5A and Figure 5B , casting the aluminum alloy material into a rim blank 20, the rim blank 20 ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com