Preparation method for resin honeycomb sandwich structure and composite material structure thereof

A honeycomb sandwich structure and composite material technology, which is applied in the preparation and application of composite materials, can solve the problems of reduced mechanical properties, high manufacturing costs, and cumbersome molding processes, and achieve reliable mechanical properties, reduced production costs, and reliable product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

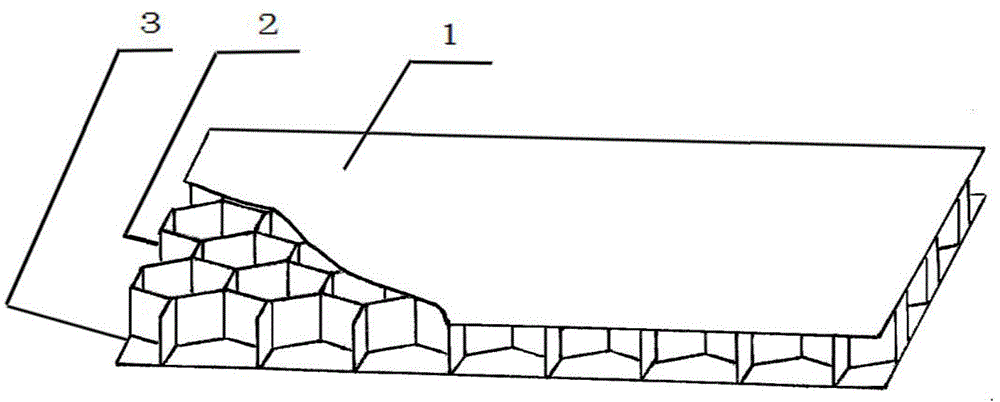

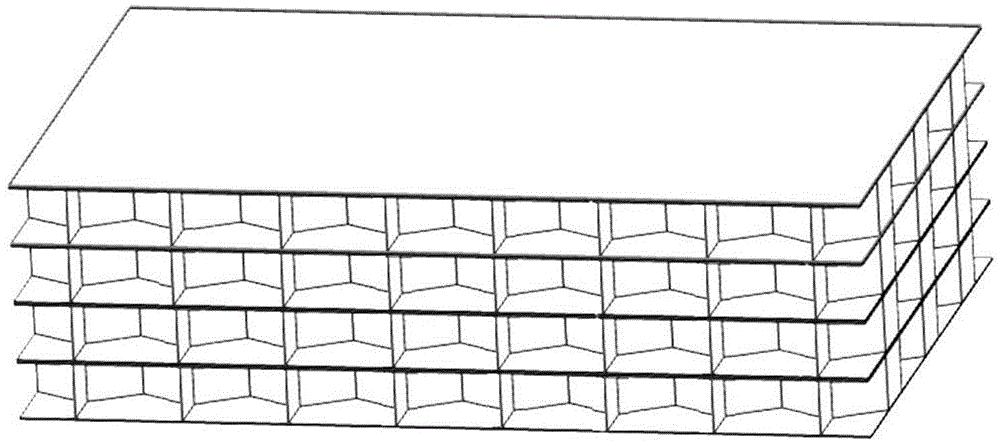

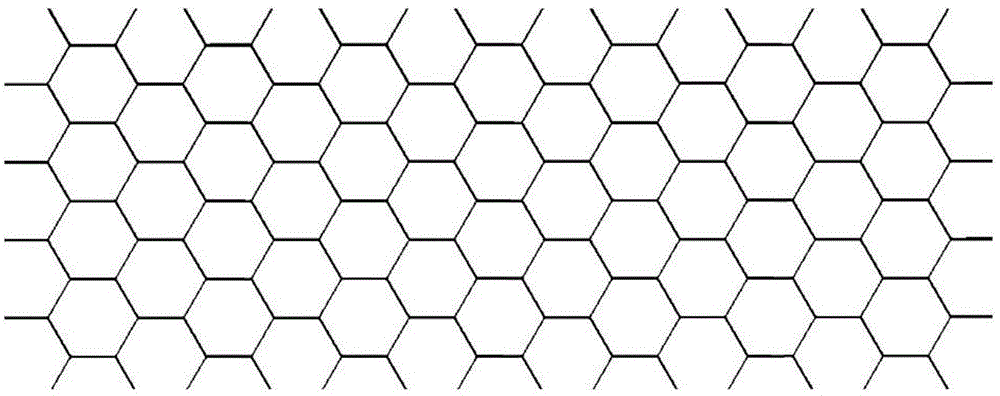

Embodiment 1

[0037] refer to Figure 5, using UG, Pro / Engineer, CAD software to establish a regular hexagon with a side length of 10mm and a honeycomb wall thickness of 0.3mm; the closed-cell honeycomb core unit is 10mm high, and the closed plane thickness is 0.3mm; the closed-cell honeycomb mandrel has a hexagonal thickness of 30mm Shaped resin honeycomb sandwich structure. Use Replicator or Cura slice software to divide the resin honeycomb sandwich structure to obtain the shape of each section, and generate the galvanometer motion code sequence sequentially. The Cute-Ⅶ photosensitive resin and carbon nanotubes of Shenzhen Baolimo Technology Co., Ltd. were placed in an ultrasonic oscillator, and oscillated for 1 hour to disperse. Pour the photosensitive resin mixture prepared in the previous step into the transparent glue tank 5 . Move the sample stage downward to contact with the bottom of the transparent glue tank 5 . The computer runs the Smart-I printing software developed by Shenz...

Embodiment 2

[0039] UG, Pro / Engineer, and CAD software are used to establish a square honeycomb sandwich structure with a side length of 10mm and a honeycomb wall thickness of 0.1mm; the closed-cell honeycomb core unit is 6mm high, and the closed plane thickness is 0.2mm; the closed-cell honeycomb mandrel has a thickness of 30mm. . Use Replicator or Cura slice software to divide the resin honeycomb sandwich structure to obtain the shape of each section, and generate the galvanometer motion code sequence sequentially. The Cute-II photosensitive resin and vapor-phase-grown carbon fiber developed by Shenzhen Baolimo Technology Co., Ltd. were placed in an ultrasonic oscillator and oscillated for 2 hours to disperse. Pour the photosensitive resin mixture prepared above into the transparent glue tank 5 . Move the sample stage downward to contact with the bottom of the transparent glue tank 5 . The computer runs the Smart-I printing software developed by Shenzhen Baolimo Technology Co., Ltd., e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com