W/O/W multiphase emulsion and method for preparing hierarchical pore SiO2 microspheres using W/O/W multiphase emulsion as formwork

A technology of multiphase emulsion and hydrochloric acid aqueous solution is applied in the field of preparing multi-level porous SiO2 microspheres, and achieves the effects of simple preparation method, regular pore structure and high thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

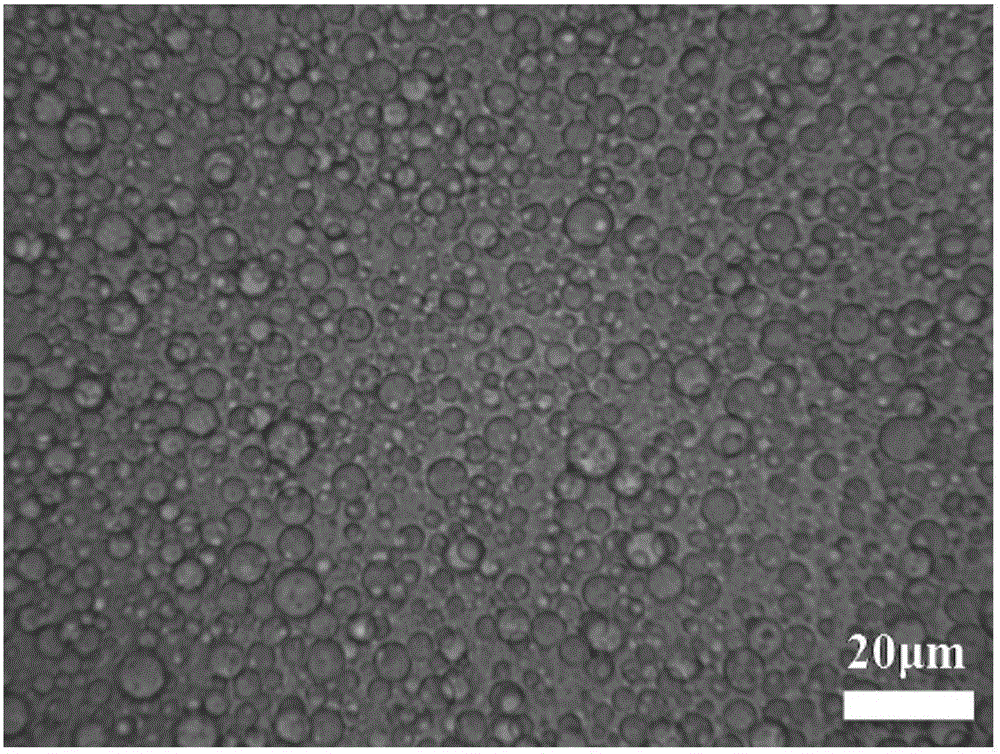

[0037] Dissolve 0.15g of small molecule stabilizer in 1mL of vinyltriethoxysilane, then add 4mL of hydrochloric acid aqueous solution with a pH value of 2, and mechanically stir at room temperature for 2 minutes at a speed of 11400 rpm to obtain W / O / W multiphase emulsion (see figure 1 ), it can be seen from the figure that the obtained multiphase emulsion droplet size is uniform.

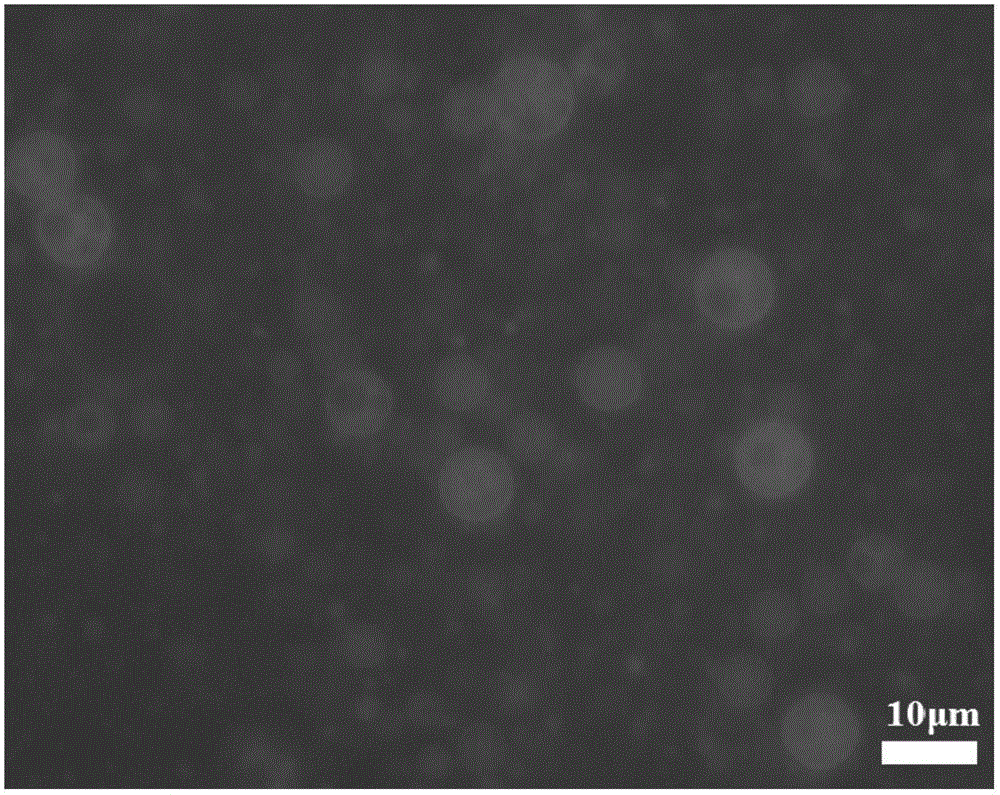

[0038] In the above preparation process, the inventor added Nile Red to vinyltriethoxysilane for dyeing, and performed fluorescence microscope characterization of the obtained multiphase emulsion. The results are shown in figure 2 , the result proves that the type of emulsion is W / O / W type multiphase emulsion.

Embodiment 2

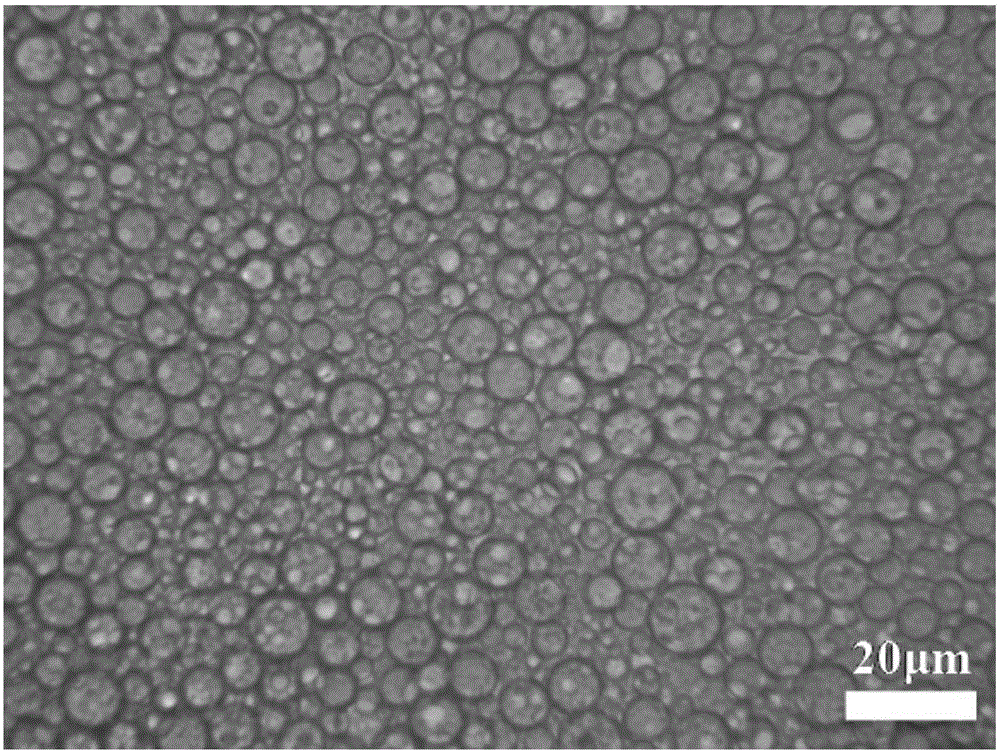

[0040] Dissolve 0.15g of small molecule stabilizer in 1mL of vinyltriethoxysilane, then add 4mL of hydrochloric acid aqueous solution with a pH value of 4, and mechanically stir at room temperature for 2 minutes at a speed of 11400 rpm to obtain W / O / W multiphase emulsion (see image 3 ), it can be seen from the figure that the droplet distribution in the obtained multiphase emulsion is uniform.

Embodiment 3

[0042] Dissolve 0.15g of small molecule stabilizer in 1mL of vinyltriethoxysilane, then add 4mL of hydrochloric acid aqueous solution with a pH value of 5, and mechanically stir at room temperature for 2 minutes at a speed of 11400 rpm to obtain W / O / W multiphase emulsion (see Figure 4 ), it can be seen from the figure that the droplet size in the obtained multiphase emulsion is uniform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com