High corrosion resistance lead-free and cadmium-free tempered glass pigment flux

A tempered glass and pigment technology is applied in the field of high corrosion resistance lead-free and cadmium-free tempered glass pigment flux, which can solve the problems of physical harm to workers, influence on organ function, air pollution, etc., and achieve harm reduction, high gloss, and pure color. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with embodiment.

[0026] All raw materials used in the examples are commercially available unless otherwise specified.

[0027] In the preparation method of the high-corrosion lead-free and cadmium-free tempered glass pigment in the embodiment, the ingredients are prepared according to the composition of the formula, the flux is prepared first, and then the pigment is prepared according to the following steps:

[0028] (1) Preparation of flux: Mix the raw materials required for the purchased flux evenly in proportion, pass through a 80-100 mesh sieve, quench in molten water at 1000-1250°C, and dry for later use;

[0029] (2) Ball milling: the flux and the colorant are mixed and ball-milled until the particle size is less than 5 microns, and the pigment is finished after being dried and pulverized.

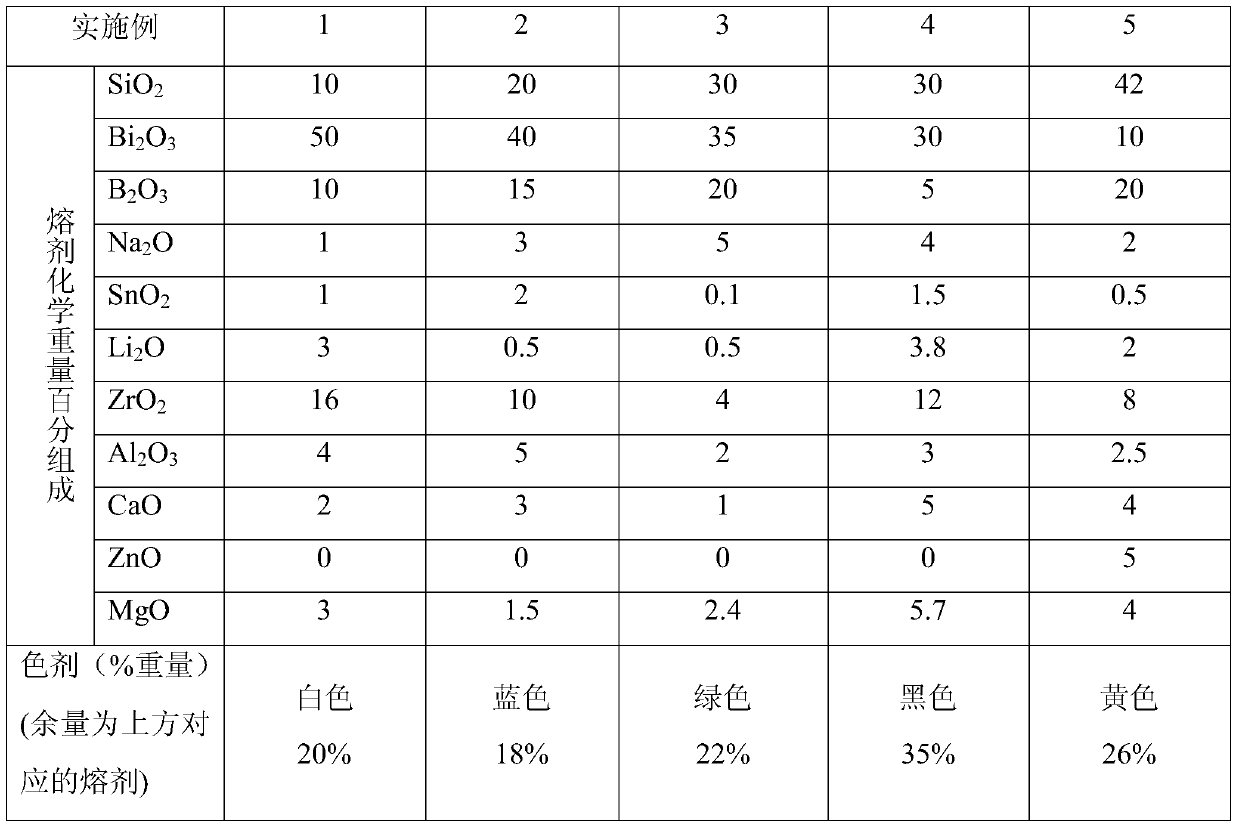

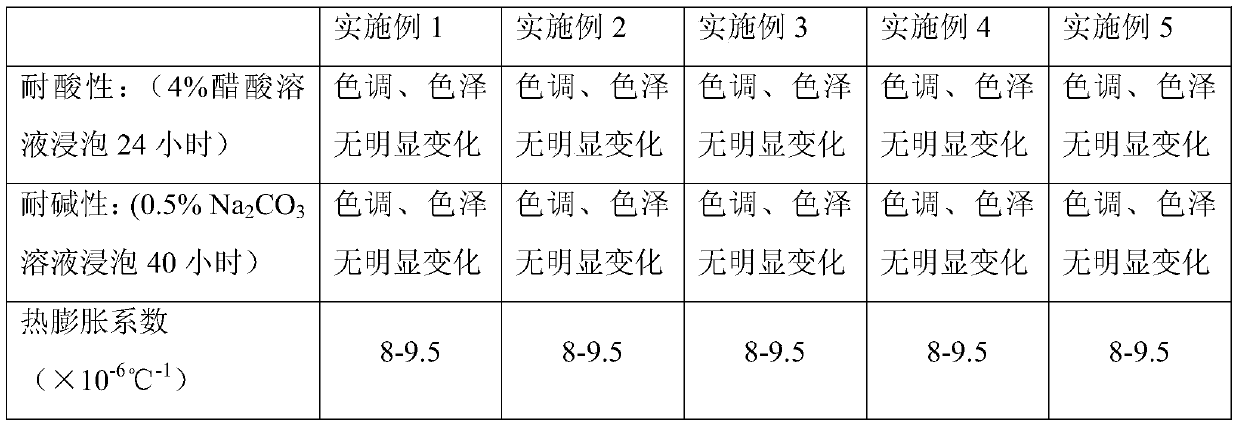

[0030] See Table 1 for the weight percent composition of the high-corrosion lead-free and cadmium-free...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com