Deep and thick sand layer covered karst cave grouting system device and construction method

A technology of grouting system and construction method, which is applied in the direction of infrastructure engineering and construction, and can solve the problems of insufficient grouting, excessive grouting, personnel and property losses, etc., so as to avoid excessive grouting, increase the difficulty of forming grooves, and avoid sand and gravel missing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

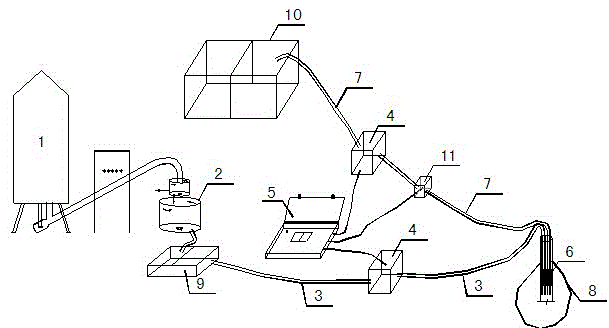

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] The grouting system equipment of the present invention is connected as figure 1 As shown, the cement tank 1, the grouting system 2 and the grouting machine 9 are connected through the grout inlet pipeline 3, and the mud recovery system is connected through the grout return pipeline 7; the grouting system includes a grouting recorder 5 and a grout stopper 6, wherein the grouting The recorder 5 is respectively connected to the flowmeter 4 and the pressure gauge 11, and the grout stopper 6 is placed on the roof of the cave 8, and the grout stopper 6 contains a grouting needle.

[0014] The flow meters 4 are respectively arranged on the grouting pipeline and the grouting pipeline.

[0015] The pressure gauge 11 is arranged on the slurry return pipeline.

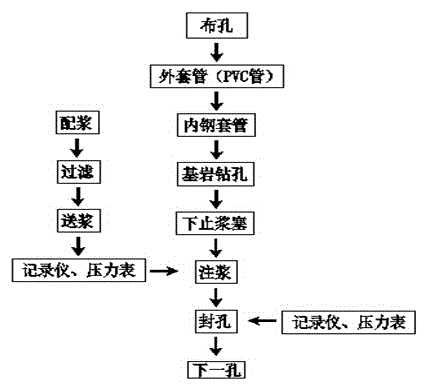

[0016] The karst grouting construction method under the deep sand layer coverage of the present invention, suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com