Method for testing even mixing degree of mixed iron mine pellet material

A test method and technology of iron ore pellets, which are applied in iron ore sinter pellets and iron and steel metallurgy fields, can solve the problems of less sampling, poor representativeness, and complex element content determination by secondary methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

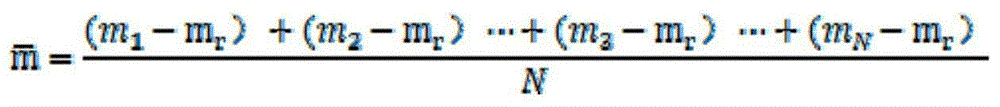

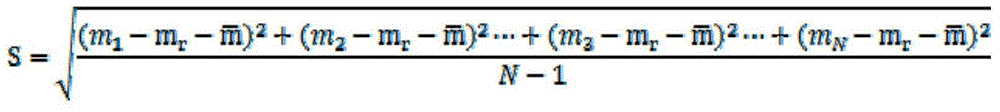

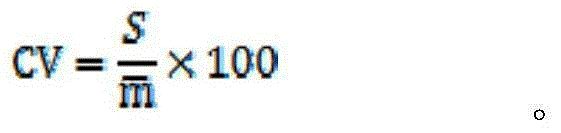

[0069] The specific steps of the test method are as follows:

[0070] (1) Take one electronic scale, one funnel, one 30ml container, one scraper, one fixed bracket, and several sealed bags; the bracket fixes the funnel, the funnel must be a certain height from the experimental platform, generally 12mm, and the container is placed under the funnel , Use an electronic scale to measure the container mass m r ;

[0071] (2). Sampling is divided into sections in the mixed materials of the pellets to be tested. In order to ensure the effectiveness and reliability of the samples, the sampling area should be in the vertical powerful mixer (ie iron ore pellet mixing equipment) as a primary mixer. The interval within 10m of the material outlet is divided into 7 sampling sections of equal length, and samples are taken from each section at the same time or simultaneously, and then the samples obtained in each section are respectively sealed in the sealed bag in step (1) Among them, the number...

Embodiment 2

[0082] The specific steps of the test method are as follows:

[0083] (1) Take one electronic scale, one funnel, one 40ml container, one scraper, one fixed bracket, and several sealed bags; the bracket fixes the funnel. The funnel must be at a certain height from the experimental platform. Take 20mm and place the container under the funnel. Use an electronic scale to measure the mass of the container m r ;

[0084] (2). Sampling is divided into sections in the mixed materials of the pellets to be tested. In order to ensure the effectiveness and reliability of the samples, the sampling area should be in the vertical powerful mixer (ie iron ore pellet mixing equipment) as a primary mixer. The interval within 10m of the material outlet is divided into 10 sampling sections of equal length, and samples are taken from each section at the same time or simultaneously, and then the samples obtained in each section are respectively sealed in a sealed bag in step (1) Among them, the number o...

Embodiment 3

[0095] Sampling at time intervals. The specific steps of the test method are as follows:

[0096] (1) Take one electronic scale, one funnel, one 40ml container, one scraper, one fixed bracket, and several sealed bags; the bracket fixes the funnel. The funnel must be at a certain height from the experimental platform. Take 20mm and place the container under the funnel. Use an electronic scale to measure the mass of the container m r ;

[0097] (2) At the material outlet of the vertical powerful mixer (ie, iron ore pellet mixing equipment) as a primary mixer, take 10 samples at a time interval of 5 seconds and pack them in the sealed bag in step (1) , The number of samples is 10, and the number of samples is recorded as N=10. According to step (1) the container volume, the weight of each sample is not less than 2 times of the material in the container;

[0098] (3) From the samples taken in step (2), import them from the funnel in step (1) until the container under the funnel is fill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com