Servo system friction compensation method based on time Coulomb friction model

A technology of friction compensation and friction model, which is applied in general control systems, control/regulation systems, simulators, etc., can solve the problems of increasing the complexity of algorithms and the amount of calculations, and achieve the reduction of data processing, simple methods, and avoidance of control algorithms and the effect of the calculation of the friction parameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Proposal of time Coulomb friction model

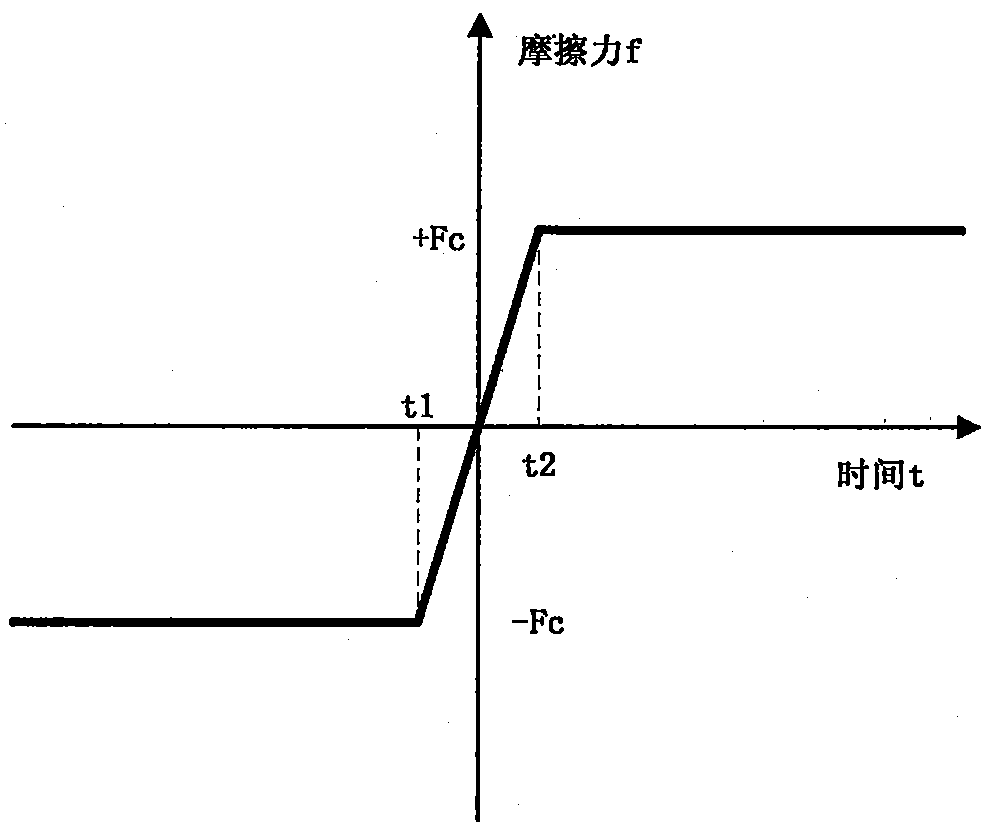

[0027] The time model of friction can be obtained from the speed model of friction. For the sake of simplicity, taking the Coulomb friction model as an example, a time Coulomb friction model is established to analyze the theoretical basis of this compensation method.

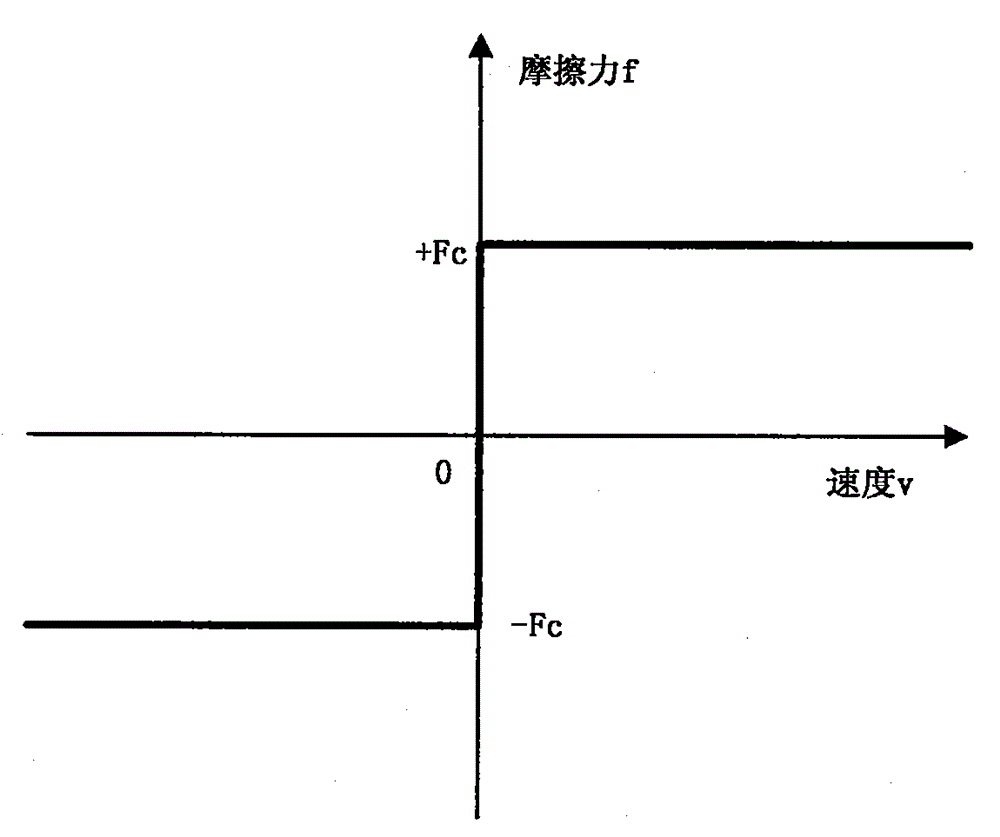

[0028] Such as figure 1 As shown, the Coulomb friction model is the simplest model, and its expression is: F=Fc*sgn(V). The Coulomb model believes that the magnitude of the friction force remains unchanged during the motion of the object. In fact, the friction force changes with the speed, so the deviation between the Coulomb friction model and the actual friction force is also the largest. Its advantage is that the expression is relatively simple, and it can reflect the change of friction force from -Fc to +Fc when the speed crosses zero, which is also the main interference factor that the servo system needs to overcome. Therefore, for the sake of simplicity...

Embodiment 2

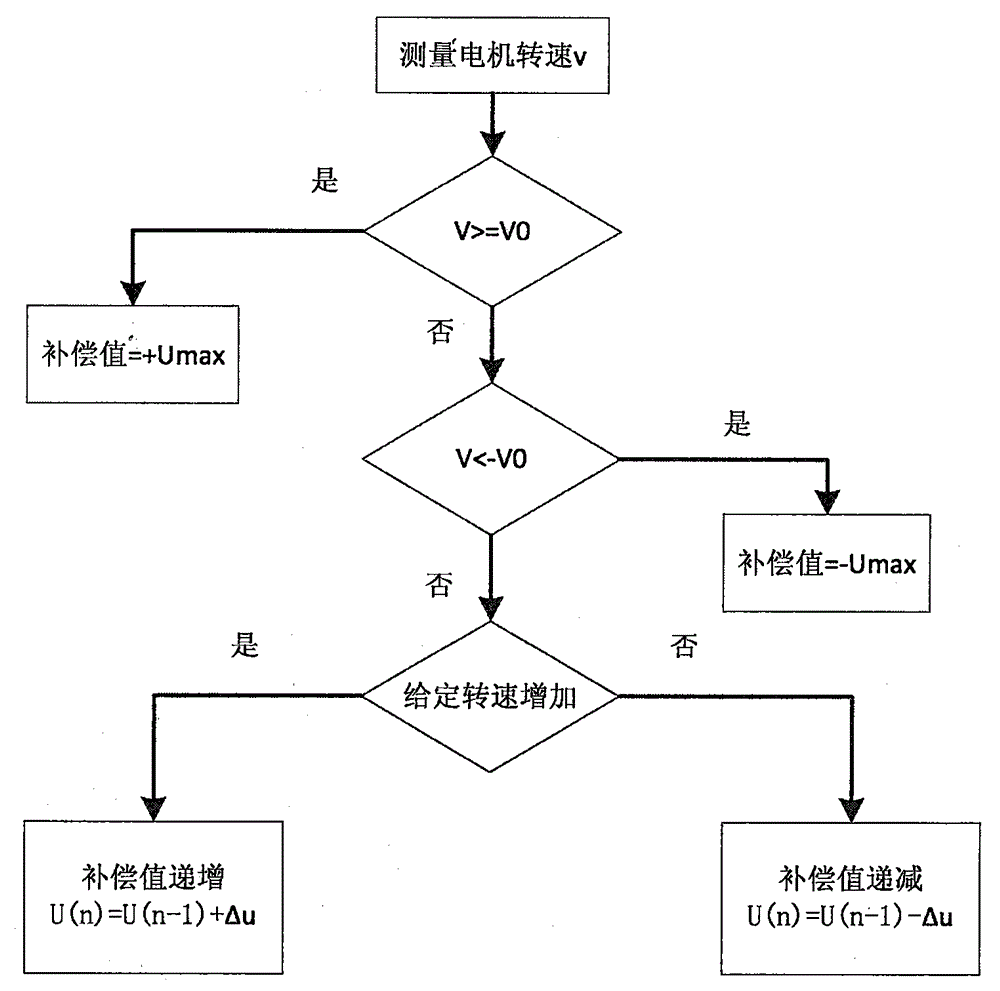

[0044] Such as Figure 5 Shown is the structural block diagram of the servo system, and the motor is affected by the friction torque during operation. Therefore, it is necessary to add a compensator in the output of the controller to counteract the influence of friction. according to image 3 As shown in the compensation flow chart, the input parameters required by the friction compensator include the given speed and the feedback speed, and the output of the friction compensator is added to the output of the PID controller as the total output of the controller.

[0045] In order to verify the effectiveness of the friction compensation method, a motor system with speed negative feedback is used for testing. The motor servo system includes TMS230F28335 DSP controller, PWM driver, motor, grating encoder, RS232 serial communication circuit and host computer, motor and drive parameters such as Image 6 shown.

[0046] Steps:

[0047] (1) Firstly, a time Coulomb friction model ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com