Petri-network-based control method for automatic manufacture system

A technology for automatic manufacturing systems and control methods, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as state explosion, system stagnation, resource failure, etc., to improve concurrency and avoid blocking states , the effect of smooth processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

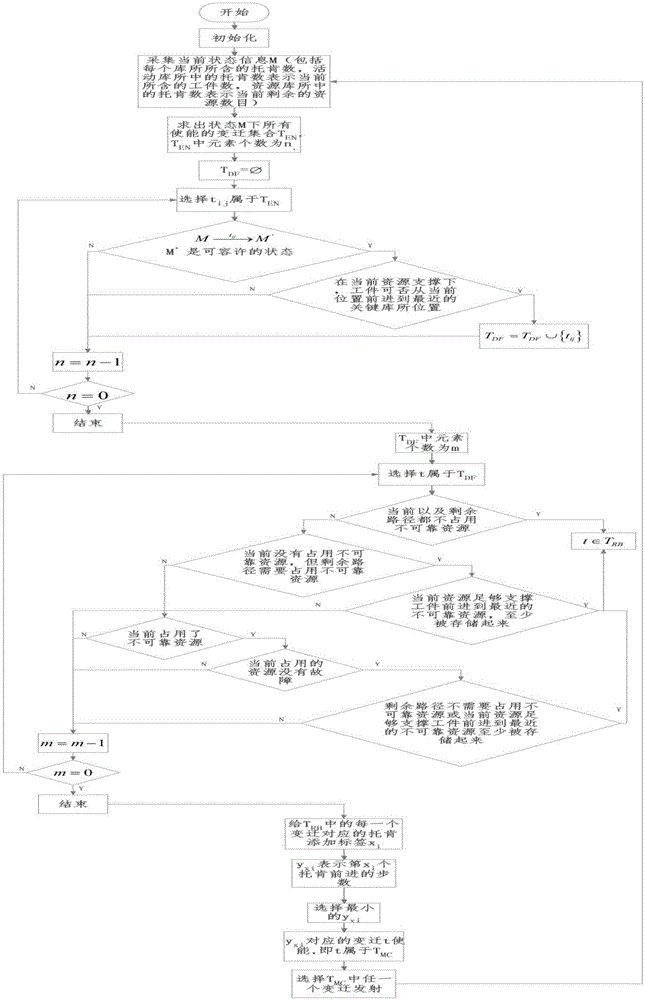

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

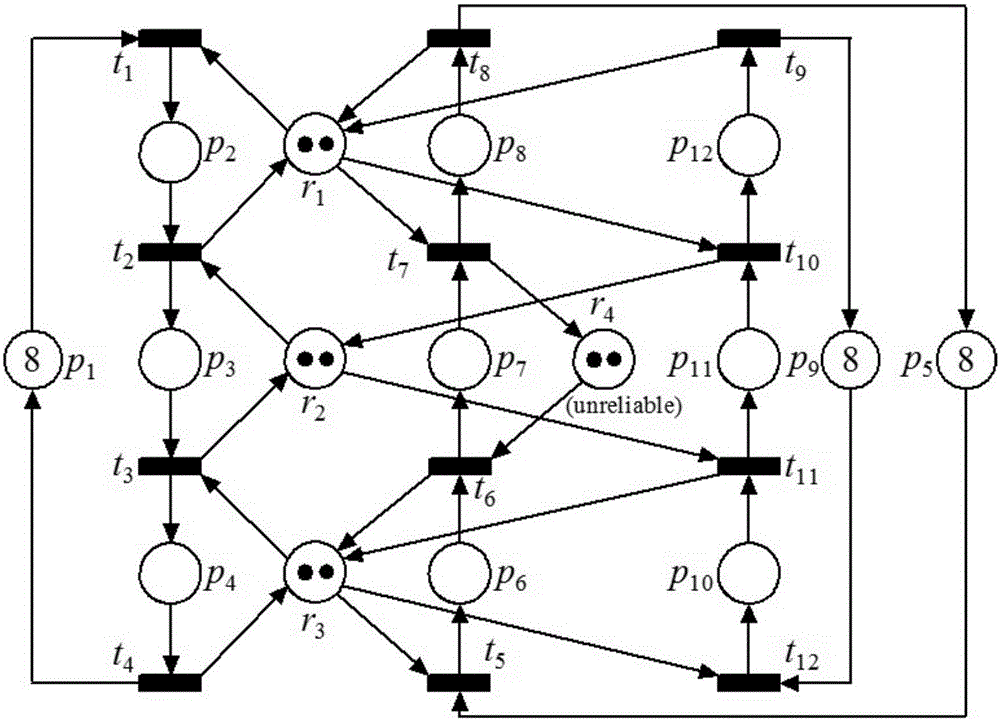

[0028] Definition 1: A production Petri net Product Petri Net (PPN) is a strongly connected ordinary Petri net (PN), N = (P, T, F), where:

[0029] 1) P=P 0 ∪P A ∪P R ,P 0 ,P A ,P R Respectively represent free warehouse, active warehouse and resource warehouse. and j∈N K ,i≠j, P R ={r i ,i∈N L}. N K , N L are all sets of natural numbers, N K ={1,2,3,...,K},N L ={1,2,3,...,L};

[0030] 2) and j∈N K ,i≠j,

[0031] 3) Depend on subnet is a strongly connected state machine such that each loop contains |p · |=1.

[0032] 4) ·· p∩P R =p ·· ∩P R , and | ·· p∩P R |=1.

[0033] 5) and represent reliable resources and unreliable resources, respectively,

[0034] Definition 2: r ∈ P R is a resource pool, H(r)=r ·· ∩P A Indicates the set of places where resource r is used.

[0035] Defin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com