Closed-loop Control System of Motorized Multi-leaf Grating Encoder

A grating encoder, electric multi-leaf technology, which is applied in the direction of using feedback control, etc., can solve the problems that the control accuracy of electric multi-leaf grating cannot be met at the same time, the CCD camera is not resistant to radiation, and it is difficult to adjust and maintain, and achieve economical savings. The effect of installation, maintenance and debugging time, reducing replacement and debugging time, and convenient wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

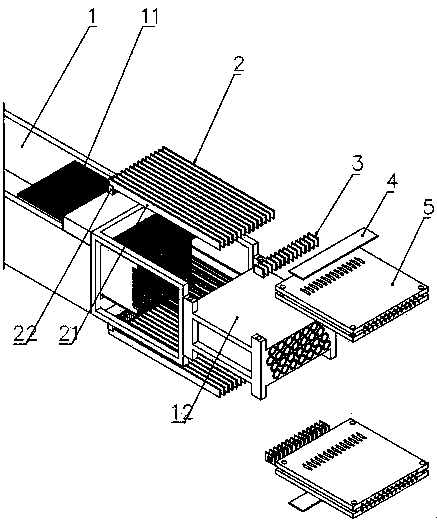

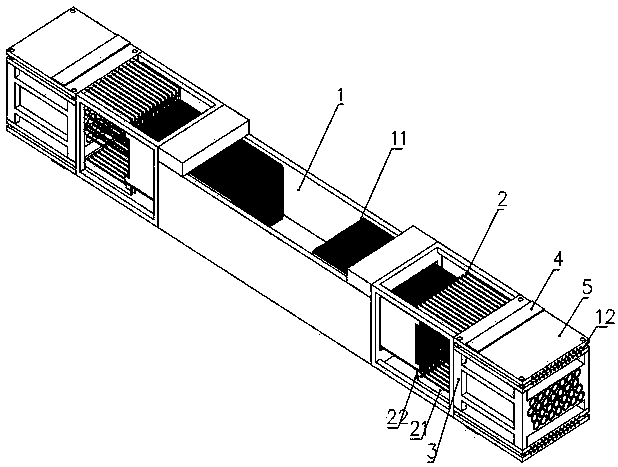

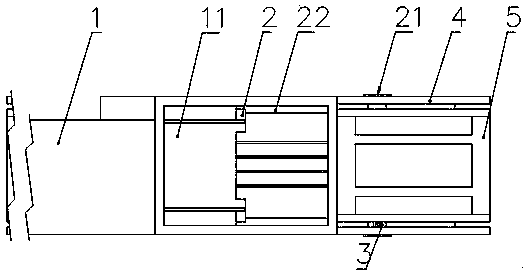

[0028] Such as Figure 1-5 As shown, the present invention includes an electric multi-leaf grating 1, and also includes a code bar 2, an integrated sensor 3, an integrated circuit board 4 and a code bar guide groove 5, and the connector 22 provided on the code bar 2 is connected to the electric multi-leaf grating 1 The blade 11 is fixed, and the code bar 2 is integrally arranged in the guide groove 54 of the code bar guide groove 5, and the code bar 2 moves linearly following the blade 11; the integrated circuit board 4 is fixed on a surface of the code bar guide groove 5; The integrated sensor 3 is composed of a circuit board 31 and a precision sensor 32 installed on the circuit board 31 , the circuit board 31 of the integrated sensor 3 is connected with the integrated circuit board 4 installed on one surface of the code bar guide groove 5 . The number of code bars and integrated sensors in this system corresponds to the number of blades. Each code bar is fixed with a single...

Embodiment 2

[0031] This embodiment is preferably as follows on the basis of Embodiment 1: in order to facilitate the free sliding of the code bar in the code bar guide groove, and to facilitate the blade to drive the code bar to perform linear motion in the code bar guide groove, the code bar guide groove 5 includes mutual The upper guide plate 51 and the lower guide plate 52 are parallel, and the upper guide plate 51 and the lower guide plate 52 are provided with fixing grooves 53 for installing the integrated sensor 3, and any fixing groove 53 is parallel to other fixing grooves 53.

Embodiment 3

[0033] The present embodiment is preferably as follows on the basis of the foregoing embodiments: on the facing surfaces of the upper guide plate 51 and the lower guide plate 52, guide grooves 54 for installing multiple bar code bars 2 are also arranged, and any guide groove 54 is mutually connected with other guide grooves 54. parallel. In this system, the guide groove of the code bar is designed with beryllium bronze material, and is matched with the code bar made of stainless steel. In the case of long-term movement, the wear on the guide groove of the code bar can be minimized as much as possible. The control system is more durable and effectively improves The use time of the system reduces the time for replacement and debugging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com