Warm rolling processing technology of low-cost high-performance hollow anchor rod

A processing technology and high-performance technology, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of increasing the cost of bolts, insufficient cost strength or toughness, and low comprehensive mechanical properties, so as to reduce early cracks Tendency, low cost, effect of improving surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

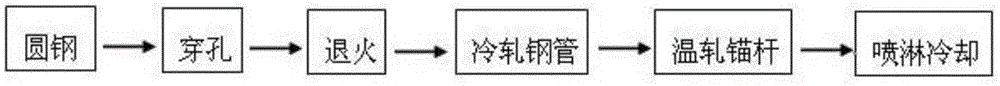

[0022] like figure 1 The present invention shown adopts following production process flow, round steel—perforation—annealing—cold-rolled steel pipe—warm-rolled bolt—spray cooling, and its specific process is as follows:

[0023] 1) Round steel: choose high-quality hot-rolled round steel, the material is 40Cr, and the specification is determined according to the specification and deformation of the required steel pipe.

[0024] 2) Piercing: The heating temperature is 1160~1190℃ when piercing, and the holding time is determined according to the diameter of the round steel, about 6~7min / cm.

[0025] 3) Annealing: Complete annealing of the blank tube after perforation, the annealing temperature is 850-900°C, and the annealing time is determined according to the wall thickness of the blank tube, about 3~5min / mm. .

[0026] 4) Cold rolling: Two-roller ring pass cold rolling mill is adopted, and the rolling deformation is 70%-90%.

[0027] 5) Warm-rolled bolt: rolling temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com