Laser marking device

A technology of laser and laser generator, which is applied in printing and other directions, can solve the problems of inconvenient changes in printing content, inability to meet diversified production needs, and inability to meet the requirements of processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

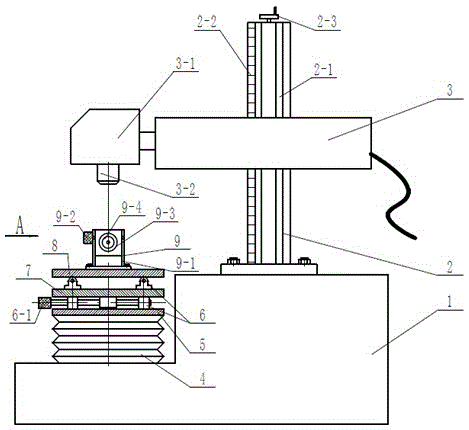

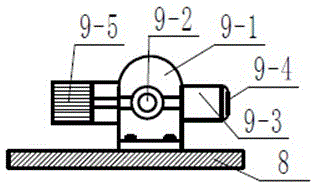

[0011] Depend on figure 1 , figure 2 Known, the structure diagram of the present invention is made up of main support 1, column 2, laser generator 3, telescopic plate 4, telescopic support plate 5, mobile support assembly 6, left and right sliding plate 7, front and rear sliding plate 8, tooling support assembly 9 , the column 2 is installed and fixed on the upper right side of the main bracket 1 by bolts, the laser generator 3 is installed on one side of the column 2, the telescopic plate 4 is fixed on the lower left side of the main bracket 1, and the telescopic support plate 5 is installed above the telescopic plate 4, The mobile support assembly 6 is arranged between the telescopic support plate 5 and the left and right sliding plates 7, the mobile support assembly 6 is arranged between the front and rear sliding plates 8 and the left and right sliding plates 7, the tooling support assembly 9 is installed above the front and rear sliding plates 8, and is in the Right bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com