Laminating non-woven fabric for high-hygroscopic drying agent, preparation method thereof and packaging bag made of laminating non-woven fabric

A technology of laminating non-woven fabric and desiccant, applied in the directions of transportation and packaging, packaging, bags, etc., can solve the problems of affecting the waterproof performance of waterproof and breathable membrane, leakage of calcium chloride aqueous solution, water seepage on the surface of products, etc., to improve mechanization The effect of production speed, excellent air permeability and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Preparation of laminated non-woven fabric for high moisture absorption desiccant

[0034] PP waterproof and breathable membrane is selected at 50g / m 2 The biaxially stretched PP waterproof and breathable membrane, the PE spunbond non-woven fabric is made of DuPont 1025D spunbonded non-woven fabric, and the adhesive is made of one-component moisture-curing polyurethane adhesive. Using point spraying method, heat the adhesive and spray it on Dupont 1025D spunbond non-woven fabric, and control the glue amount at 5-8g / m 2 Within the range, the biaxially stretched PP waterproof breathable film is laminated on the DuPont 1025D spunbonded nonwoven fabric, so that the PP waterproof breathable film and the PE spunbonded nonwoven fabric are combined together to obtain the high moisture absorption desiccant of the present invention. Laminated non-woven fabric.

Embodiment 2

[0035] Example 2: Preparation of laminated non-woven fabric for high moisture absorption desiccant

[0036] PP waterproof and breathable membrane is selected at 50g / m 2 The biaxially stretched PP waterproof and breathable membrane, the PE spunbond non-woven fabric is made of DuPont 1443R spunbonded non-woven fabric, and the adhesive is made of EVA hot melt adhesive. Using spot spraying method, heat the adhesive and spray it on Dupont 1443R spunbond non-woven fabric, and control the glue amount at 5-8g / m 2 Within the range, the biaxially stretched PP waterproof and breathable film is laminated on the DuPont 1443R spunbonded nonwoven fabric, thereby making the multi-film nonwoven fabric for the high moisture absorption desiccant of the present invention.

Embodiment 3

[0037] Example 3: Preparation of laminated non-woven fabric for high moisture absorption desiccant

[0038] PP waterproof and breathable membrane is selected at 70g / m 2 The biaxially stretched PP waterproof and breathable membrane, the PE spunbond non-woven fabric is DuPont 1056D spunbond non-woven fabric, and the adhesive is a one-component moisture-curing polyurethane adhesive. Using the coating method, the binder is heated and coated on the DuPont 1056D spunbonded non-woven fabric, and the amount of glue is controlled at 5-8g / m 2 Within the range, the biaxially stretched PP waterproof and breathable film is laminated on the DuPont 1056D spunbonded nonwoven fabric to obtain the multi-film nonwoven fabric for the high moisture absorption desiccant of the present invention.

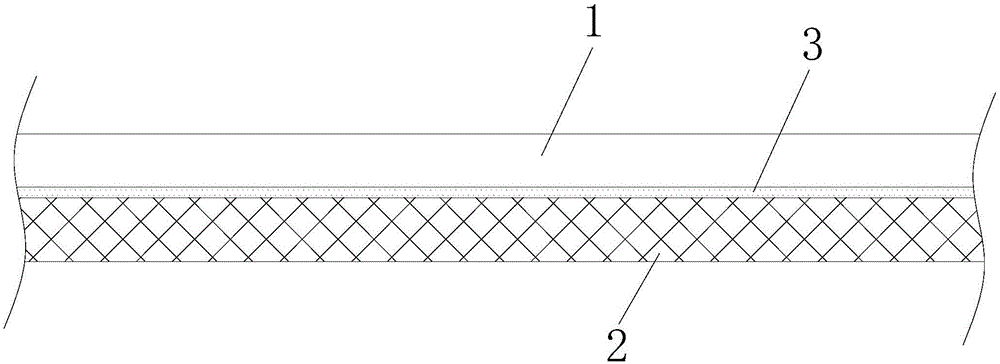

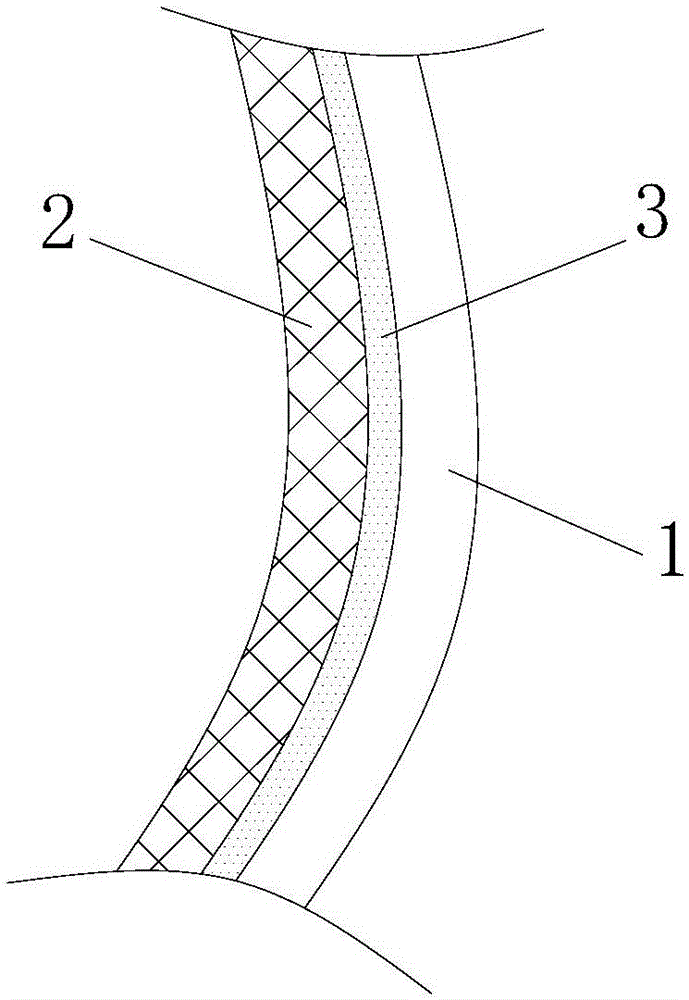

[0039] refer to figure 1 As shown, it is not difficult to see that in the above three examples, the prepared laminated nonwoven fabrics for high moisture absorption desiccant are composed of PP waterpro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com