Coarse diatom ooze powder and production process thereof

A diatom mud powder and production process technology, applied in the field of coatings, can solve the problems of difficult control of the construction window, large energy consumption, and high labor costs, and achieve the effects of prolonging the construction window period, increasing the fusion rate, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

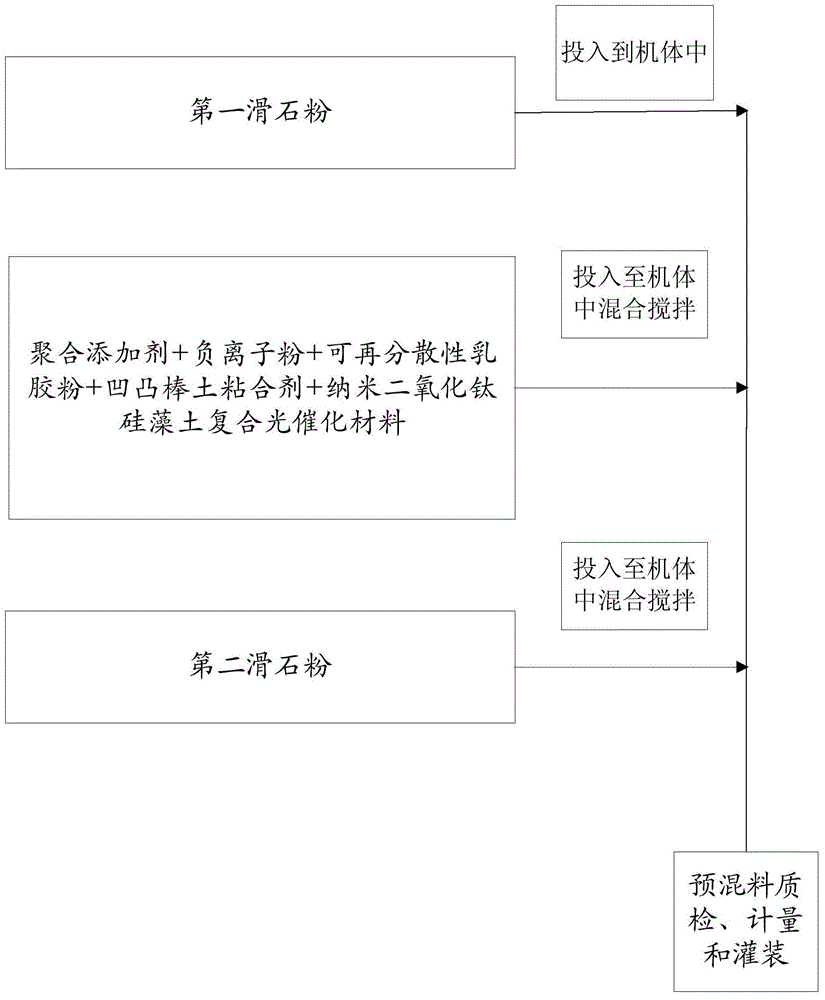

[0069] In the preparation of the premix in the present invention, there is no special limitation on the equipment used for mixing and stirring, and the equipment known to those skilled in the art that can realize the mixing and stirring of diatom ooze powder is sufficient. The present invention preferably adopts the JZ-02Q high-speed cutting and stirring dispersing machine for mixing and stirring.

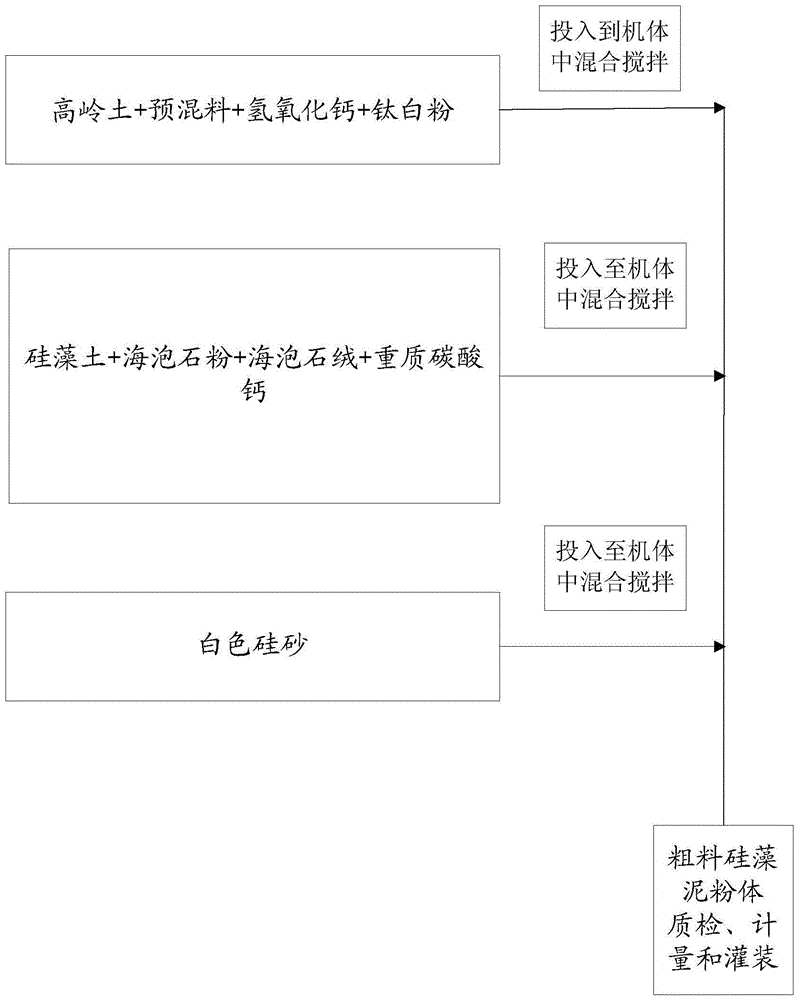

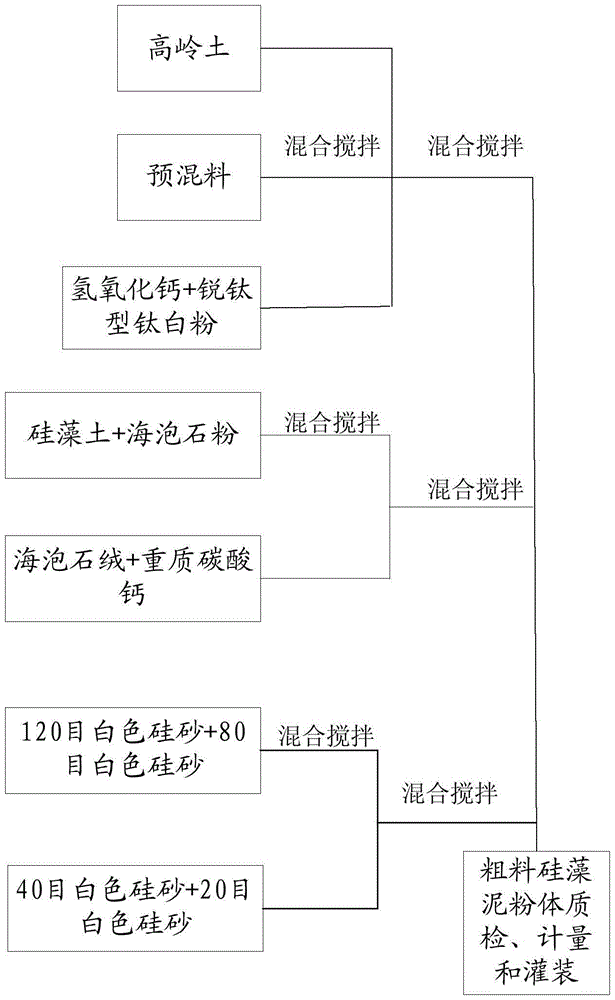

[0070] After obtaining the premix, mix and stir the premix, kaolin, calcium hydroxide and titanium dioxide, then add diatomaceous earth, sepiolite powder, sepiolite wool and heavy calcium carbonate, mix and stir, and finally add white silica sand Mix and stir to obtain coarse diatom mud powder.

[0071] In the present invention, there is no special limitation on the instruments used in the preparation and mixing of the coarse diatom ooze powder, and the instruments known to those skilled in the art can realize the mixing and stirring of the diatom ooze powder. In the present inven...

Embodiment 1

[0138] Embodiment 1 prepares the premix of coarse material diatom ooze powder

[0139] The model is JZ-02Q high-speed cutting and stirring dispersing machine for the preparation of premix

[0140]First put 25wt% of 800 mesh talc powder into the high-speed cutting and stirring disperser, then add 8.4wt% of polyvinyl acetate redispersible latex powder, 16.7wt% of attapulgite, 3.3wt% of methyl hydroxypropyl Base cellulose ether, 5wt% wood fiber, 1.7wt% seaweed powder, 6.6wt% sulfonated naphthalene wetting and dispersing agent and 8.3wt% nano-titanium dioxide diatomite composite photocatalytic material at 1000 rpm After mixing and stirring for 2 minutes, 25 wt% of 800-mesh talcum powder was added and mixed and stirred for 7 minutes under the condition of 1000 rpm to obtain a premix. The premix quality inspection, metering and filling equipment are used.

Embodiment 2

[0142] The model is JZ-02Q high-speed cutting and stirring dispersing machine for the preparation of premix

[0143] First, 19wt% of 800-mesh talcum powder was put into the high-speed cutting and stirring disperser, followed by adding 12wt% of polyvinyl acetate redispersible latex powder, 16.7wt% of attapulgite, and 4.8wt% of methyl hydroxypropyl Cellulose ether, 6.4wt% wood fiber, 3.2wt% seaweed powder, 7.9wt% sulfonated naphthalene wetting and dispersing agent and 11wt% nano-titanium dioxide diatomite composite photocatalytic material under the condition of 1300 rpm After mixing and stirring for 2 minutes, 19 wt% of 800-mesh talcum powder was added and mixed and stirred for 7 minutes under the condition of 1300 rpm to obtain a premix. The premix quality inspection, metering and filling equipment are used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com