Pinacolone preparation method

A technology of pinacolone and reaction time, which is applied in the direction of hydrogen halide addition preparation, condensation preparation of carbonyl compounds, and hydrocarbon production from oxygen-containing organic compounds, etc., which can solve the problem of increased production cost of pinacolone, low conversion rate, and long reaction time and other problems, to achieve the effect of low equipment requirements, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

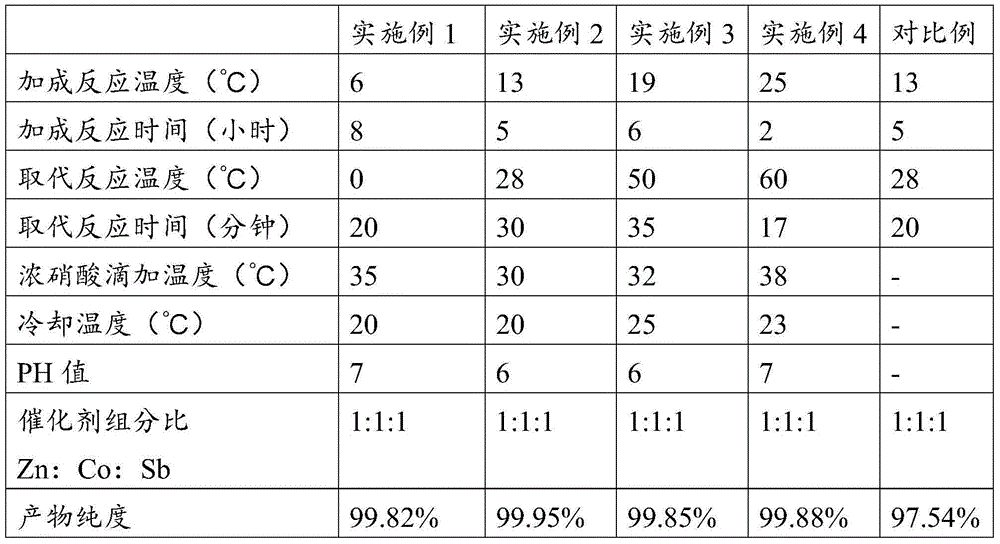

[0019] The preparation method of pinatone comprises steps:

[0020] (1) Isoamyl alcohol is dehydrated to obtain isopentene, and then reacted with hydrochloric acid to obtain isopentyl chloride, the reaction temperature is 5-25°C, and the reaction time is 2-8 hours;

[0021] (2), under the action of Zn / Co / Sb composite catalyst, react the methanol solution of chloroisopentane and sodium methylate, the mol ratio of each component in the Zn / Co / Sb composite catalyst is (0.7~1.2 ):(0.5~1.5):(0.7~1.2). The reaction temperature is 0-60° C., the reaction time is 15-35 minutes, and the pinatone is obtained.

[0022] (3), pinacolone is dissolved in the carbon tetrachloride solution, then drips concentrated nitric acid at 30~40 ℃, the mass ratio of concentrated nitric acid is 65%. Cool to 20-25°C, filter out the white solid salt, then dissolve the white solid salt in carbon tetrachloride solution, adjust the pH value to 6-7, remove the solvent, and obtain the purified pinacolone solid. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com