Butyl rubber/polyamide thermoplastic vulcanized rubber and preparation method thereof

A thermoplastic vulcanizate and butyl rubber technology, applied in the field of polymer materials, can solve the problems of high requirements of industrial production and the inability to achieve the compatibilization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Preparation of compatibilizer

[0022] The self-made compatibilizer is the oligomer of 4-ethylstyrene and maleic anhydride, and the monomer 4-ethylstyrene and maleic anhydride and azobisisobutyronitrile ( AIBN) was dissolved in tetrahydrofuran (THF), and N was introduced into the solution 2 20min to remove oxygen. Wherein the mass addition of 4-ethylstyrene and maleic anhydride accounts for 15% of the THF mass, and the initiator AIBN accounts for 1.0% of the THF mass. Subsequently, the above solution was polymerized in a constant temperature water bath at 55° C. for 6 hours, and oligomers were precipitated with methanol. The resulting oligomer was dissolved in acetone and precipitated out with methanol. After being purified three times in this way, it was dried in an oven at 50°C.

[0023] 2. Preparation of thermoplastic vulcanizate (TPV)

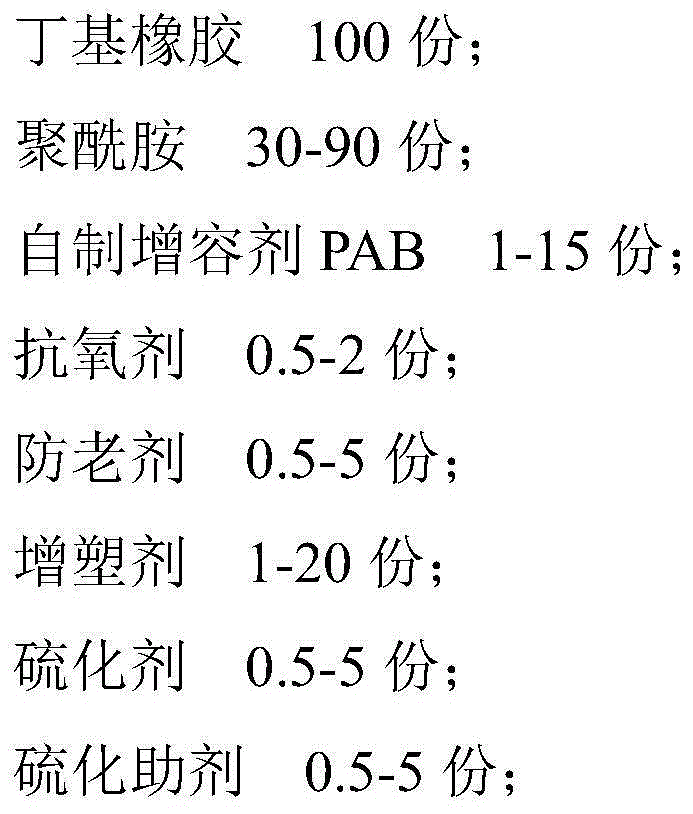

[0024] According to the following basic composition and mass parts:

[0025]

[0026]

[0027] Mix polyamide and but...

Embodiment 2

[0033] 1. The preparation method of the compatibilizer is the same as in Example 1, except that the mol ratio of the monomer 4-ethylstyrene and maleic anhydride used is 1 / 20, and the mass addition of the two accounts for 45% of the THF mass. %, the mass of AIBN accounts for 8% of the mass of THF, the constant temperature is 75°C, and the polymerization time is 10 hours.

[0034] 2. Preparation of thermoplastic vulcanizate (TPV)

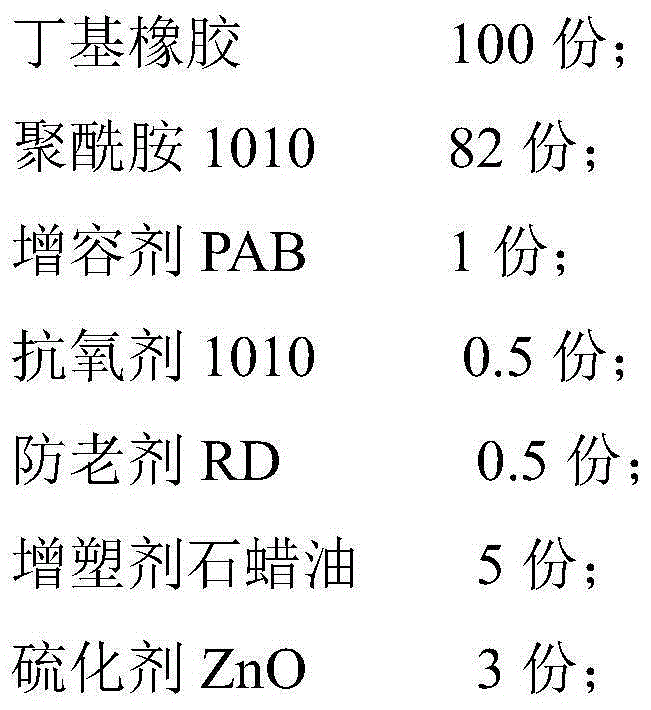

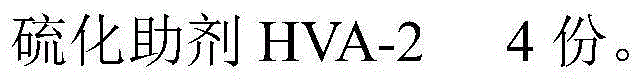

[0035] According to the following basic composition and mass parts:

[0036]

[0037]

[0038] Mix polyamide and butyl rubber at 200°C, add compatibilizer and antioxidant, after mixing evenly, discharge and cool to room temperature; then mix with antioxidant, plasticizer, vulcanizing agent and vulcanization assistant Mix evenly to obtain a rubber-plastic premix; place the rubber-plastic premix in a single-screw extruder for dynamic vulcanization, set the screw temperature at 200°C, and rotate at 500 rpm, and dynamically vulcanize to obtain buty...

Embodiment 3

[0044] 1. The preparation method of the compatibilizer is the same as in Example 1. The difference is that the mol ratio of the monomer α-methylstyrene and glycidyl methacrylate used is 1 / 10, and the mass addition of the two accounts for THF 25% by mass, AIBN mass accounted for 0.1% THF mass, the constant temperature was 65°C, and the polymerization time was 13 hours.

[0045] 2. Preparation of thermoplastic vulcanizate (TPV)

[0046] According to the following basic composition and mass parts:

[0047]

[0048] Mix polyamide and butyl rubber at 190°C, add compatibilizer and antioxidant, after mixing evenly, discharge and cool to room temperature; then mix with antioxidant, plasticizer, vulcanizing agent and vulcanization assistant Mix evenly to obtain a rubber-plastic premix; place the rubber-plastic premix in a twin-screw extruder for dynamic vulcanization, set the screw temperature at 190°C, and rotate at 700 rpm, and dynamically vulcanize to obtain butyl rubber / polyami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com