Sandy soil saline-alkali soil structure conditioning method with moire stone soil deep loosening agent

A technology for soil deep loosening and soil structure, which is applied in the field of sandy soil saline-alkali soil structure conditioning and saline-alkali soil structure conditioning. It can solve the problems of reducing soil salinity and alkalinity in saline-alkali soil, poor mechanical stability of aggregate structure, and poor water retention of saline-alkali soil. , to achieve the effect of increasing water holding capacity, improving soil water holding capacity and improving mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

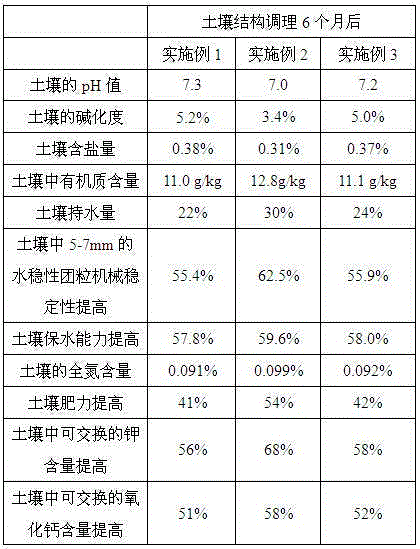

Examples

Embodiment 1

[0031] Embodiment 1 A kind of chamorite soil subsoiling agent

[0032] Described soil deep loosening agent, the mass ratio of each component is:

[0033] 35 parts of chapierite, 20 parts of limestone, 15 parts of vinyl acetate and maleic acid copolymer, 4 parts of jelly-like bacillus, 7 parts of citric acid, 2 parts of asparagus residue, 12 parts of sawdust, acrylic acid / acrylamide copolymer 0.5 parts of water retaining agent, 4 parts of carbonized chaff, 3 parts of marshmallow powder, and 2 parts of potassium dihydrogen phosphate.

[0034] The sawdust has a water content of 7-10%, and the particles are less than 50 mesh;

[0035] The limestone has a calcium content greater than 50%;

[0036] The hollyhock powder has a particle size of less than 100 mesh.

Embodiment 2

[0037] Embodiment 2 A kind of chrysotile soil subsoiling agent

[0038] Described soil deep loosening agent, the mass ratio of each component is:

[0039] 40 parts of chapierite, 25 parts of limestone, 18 parts of vinyl acetate and maleic acid copolymer, 7 parts of jelly-like bacillus, 12 parts of citric acid, 3 parts of asparagus residue, 15 parts of sawdust, acrylic acid / acrylamide copolymer 0.7 parts of water retaining agent, 7 parts of carbonized chaff, 5 parts of marshmallow powder, and 5 parts of potassium dihydrogen phosphate.

[0040] The sawdust has a water content of 7-10%, and the particles are less than 50 mesh;

[0041] The limestone has a calcium content greater than 50%;

[0042] The hollyhock powder has a particle size of less than 100 mesh.

Embodiment 3

[0043] Embodiment 3 A kind of chamorite soil subsoiling agent

[0044] Described soil deep loosening agent, the mass ratio of each component is:

[0045] 45 parts of chapirite, 30 parts of limestone, 22 parts of vinyl acetate and maleic acid copolymer, 10 parts of jelly-like Bacillus, 14 parts of citric acid, 5 parts of asparagus residue, 18 parts of sawdust, acrylic acid / acrylamide copolymer 0.8 parts of water retaining agent, 9 parts of carbonized chaff, 8 parts of marshmallow powder, and 7 parts of potassium dihydrogen phosphate.

[0046] The sawdust has a water content of 7-10%, and the particles are less than 50 mesh;

[0047] The limestone has a calcium content greater than 50%;

[0048] The hollyhock powder has a particle size of less than 100 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Water salinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com