Nucleating agent containing rare earth and application of nucleating agent to spheroidal graphite cast iron smelting

An inoculant and rare earth technology, applied in the field of metallurgy, can solve problems such as damage to the structural consistency of castings, increase in graphite ball density, mechanical and stability effects, and achieve the effects of avoiding casting defects, improving fluidity, and promoting spheroidization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

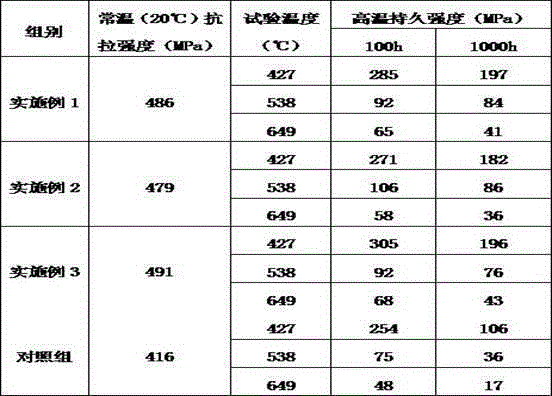

Examples

Embodiment 1

[0018] The weight percent of the inoculant containing rare earth is: 0.001% of rare earth, 0.018% of lead, 0.008% of antimony, 60% of silicon, 8% of calcium, 5% of magnesium, 1.2% of aluminum, and the balance is iron and unavoidable trace elements.

Embodiment 2

[0020] The weight percent of the inoculant containing rare earth is: 0.003% of rare earth, 0.026% of lead, 0.012% of antimony, 64% of silicon, 6% of calcium, 3% of magnesium, 0.8% of aluminum, and the balance is iron and unavoidable trace elements.

Embodiment 3

[0022] The weight percent of said inoculant containing rare earth is: 0.003% of rare earth group, 0.02% of lead, 0.01% of antimony, 58% of silicon, 12% of calcium, 4% of magnesium, 1.5% of aluminum, and the balance is iron and unavoidable trace element.

[0023] In the smelting of nodular cast iron, the nodular cast iron is inoculated three times to increase the mechanical properties and stability of the nodular cast iron. The use of the inoculant is as follows:

[0024] The first inoculation treatment: when preparing for spheroidization, 70% of the spheroidizer in the spheroidization bag is covered with an inoculant with a mass equivalent to 0.17-0.24% of the molten iron and a particle size of 7-12 mm. The remaining 30% of the nodulizer is evenly covered on the nodulizer, and then the hot metal is discharged into the nodulizer bag to complete the first inoculation treatment;

[0025] The second inoculation treatment: when the molten iron in the nodularization ladle reaches h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com