Nano chitosan base quaternary alkyl ammonium starch ether compound antibacterial paper, preparation and application thereof

A technology of nano-chitosan and quaternary ammonium alkyl, which is applied in the direction of paper, papermaking, textiles and papermaking, can solve the problems of paper strength, safety and environmental protection defects, single inorganic antibacterial materials, microbial resistance, etc., and achieve excellent physical and chemical properties. Performance, improve paper strength, good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Dissolve 5g chitosan in 3% acetic acid solution to make 4mg / mL chitosan solution, filter with 0.45μm microporous membrane; filter 4mg / mL sodium tripolyphosphate (TPP) solution with 0.22μm microporous Pore membrane filtration. After mixing 30 mL of the above-mentioned chitosan solution with 15 mL of the TPP solution, adjust the pH to 6 with 2mol / L NaOH solution, then carry out ultrasonic oscillation (output power 70W, ultrasonic oscillation in an ice-water bath for 10 s, cycle 20 times, interval 5 s), and finally obtain Nano chitosan dispersion;

[0027] (2) Beat the bleached wood pulp, then add nano-chitosan dispersion to the slurry (the mass ratio of nano-chitosan to bleached wood pulp is 1:100), stir evenly, and then pass through the paper former Manufactured to obtain nano-chitosan antibacterial paper.

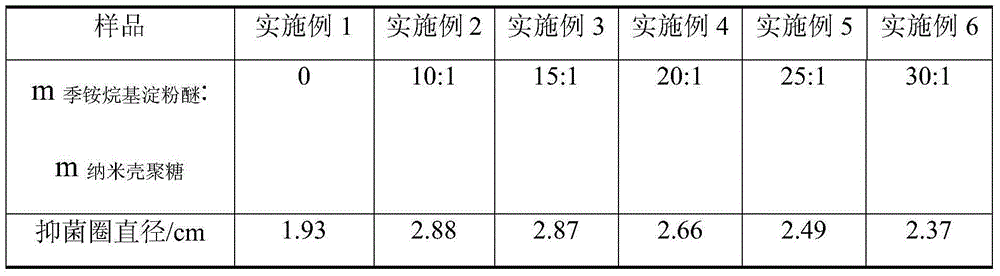

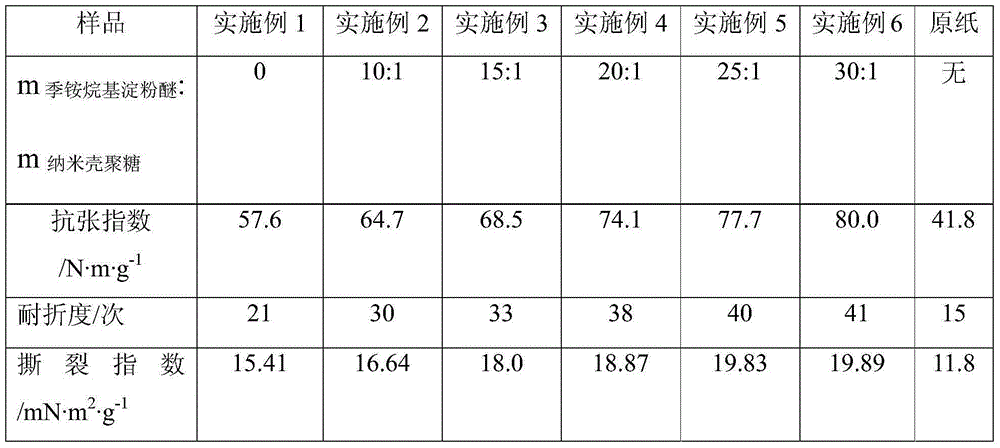

[0028] The size of the antibacterial zone of nano-chitosan antibacterial paper prepared above is shown in Table 1, and the tensile strength, tear strength, a...

Embodiment 2

[0030] A kind of nano chitosan base quaternary ammonium alkyl starch ether composite antibacterial paper, its preparation method is as follows:

[0031] (1) Dissolve 5g chitosan in 2% acetic acid solution to make 4mg / mL chitosan solution, filter with 0.45μm microporous membrane; filter 4mg / mL sodium tripolyphosphate (TPP) solution with 0.22μm microporous Pore membrane filtration. After mixing 30 mL of the above-mentioned chitosan solution with 20 mL of the TPP solution, adjust the pH to 5 with 2mol / L NaOH solution, then carry out ultrasonic oscillation (output power 70W, ultrasonic oscillation in an ice-water bath for 20 s, cycle 15 times, interval 5 s), and finally obtain Nano chitosan dispersion;

[0032] (2) Take 30 mL of quaternary ammonium alkyl starch ether solution with a mass concentration of 4%, then put it in a constant temperature water bath at 95°C, gelatinize for 20 minutes under constant stirring, and finally inject a certain amount of distilled water to adjus...

Embodiment 3

[0036] A kind of nano chitosan base quaternary ammonium alkyl starch ether composite antibacterial paper, its preparation method is as follows:

[0037] (1) Dissolve 5g of chitosan in 2% acetic acid solution to form a 3mg / mL chitosan solution, and filter it with a 0.45μm microporous membrane; Pore membrane filtration. After mixing 40 mL of the above-mentioned chitosan solution with 20 mL of the TPP solution, adjust the pH to 6 with 1mol / L NaOH solution, then carry out ultrasonic oscillation (output power 70W, ultrasonic oscillation in an ice-water bath for 30 s, cycle 10 times, interval 5 s), and finally obtain Nano chitosan dispersion;

[0038] (2) Take 60mL of quaternary ammonium alkyl starch ether solution with a mass concentration of 3%, then put it into a constant temperature water bath at 85°C, gelatinize for 30min under constant stirring, and finally inject a certain amount of distilled water to adjust the mass concentration to 1%. , so as to obtain the quaternary a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com