Whole sound insulation floor and construction method thereof

A construction method and sound insulation technology, which is applied to floors, building components, buildings, etc., can solve the problems of large reduction in net height and large increase in load, and achieve convenient laying, remarkable effects, and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

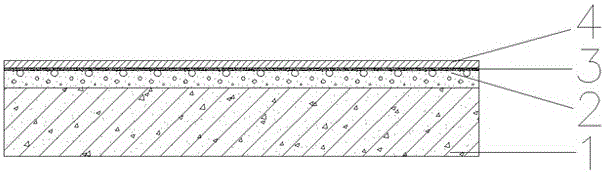

[0023] as attached figure 1 As shown in , the sound insulation floor of the present invention is composed of a reinforced concrete structure floor 1, a sound insulation leveling layer 2, a bonding layer 3 and a surface layer material 4, which are sequentially stacked from bottom to top. The base layer is a reinforced concrete structure floor 1, and the middle layer is The sound insulation leveling layer 2, the upper layer is an adhesive layer 3 and a surface material 4, and the adhesive layer 3 is located between the sound insulation leveling layer 2 and the surface material 4.

[0024] In this embodiment, the sound insulation leveling adhesive material used for the sound insulation leveling layer of the integral sound insulation floor is cement-based polymer dry powder material. The cement-based polymer dry powder material includes raw materials in parts by weight: 60 parts of cement, 25 parts of vibration-damping and sound-insulating components, 4 parts of sound-absorbing an...

Embodiment 2

[0042] The difference from Example 1 is that the sound insulation leveling adhesive material used in the sound insulation leveling layer of the integral sound insulation floor is a gypsum-based polymer dry powder material. The gypsum-based polymer dry powder material includes raw materials in parts by weight: 68 parts of building gypsum, 20 parts of vibration-damping and sound-insulating components, 3.5 parts of sound-absorbing and sound-insulating components, 0.4 parts of stress-dispersing components, and 7 parts of reinforcing components. 0.6 part of tackifier, 0.3 part of water-retaining additive, and 0.2 part of water-resistant additive.

[0043] Building gypsum is a building gypsum produced from mineral gypsum.

[0044] The vibration and sound insulation components are rubber particles with a particle size of 2 mm.

[0045] The sound-absorbing and sound-insulating components are expanded vitrified microbeads with a particle size of 2mm.

[0046] The stress dispersing co...

Embodiment 3

[0060] The difference from Example 1 is that the sound insulation leveling adhesive material used in the sound insulation leveling layer of the integral sound insulation floor is cement-based polymer dry powder material. The cement-based polymer dry powder material includes raw materials in parts by weight: 55 parts of cement, 25 parts of vibration-damping and sound-insulating components, 5 parts of sound-absorbing and sound-insulating components, 0.7 parts of stress-dispersing components, 13 parts of reinforcing components, and 0.9 part of adhesion aid, 0.3 part of water retention aid, and 0.1 part of anti-cracking aid.

[0061] The cement is slag portland cement of grade P.S42.5.

[0062] The vibration and sound insulation components are rubber particles with a particle size of 3mm.

[0063] The sound-absorbing and sound-insulating components are expanded vitrified microbeads with a particle size of 2mm.

[0064] The stress dispersing component is expanded polystyrene foam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com