A drilling fluid circulation manifold

A drilling fluid circulation and manifold technology, applied in the field of oil drilling, can solve the problems of different welding methods, low safety factor, large vibration, etc., and achieve the effects of reducing pressure loss, high bearing strength and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

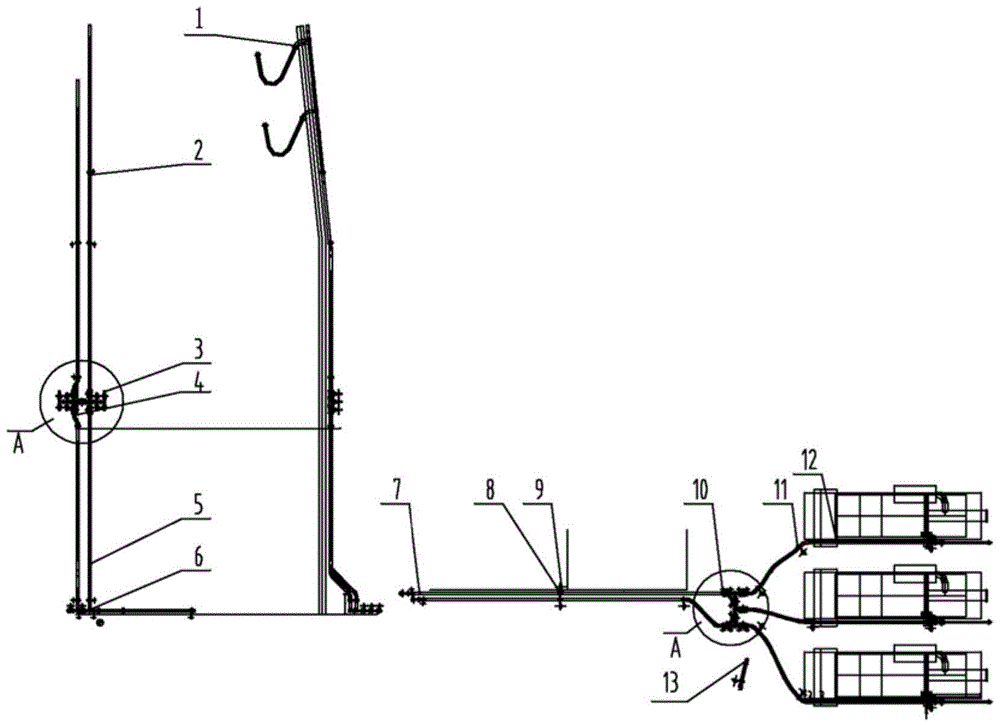

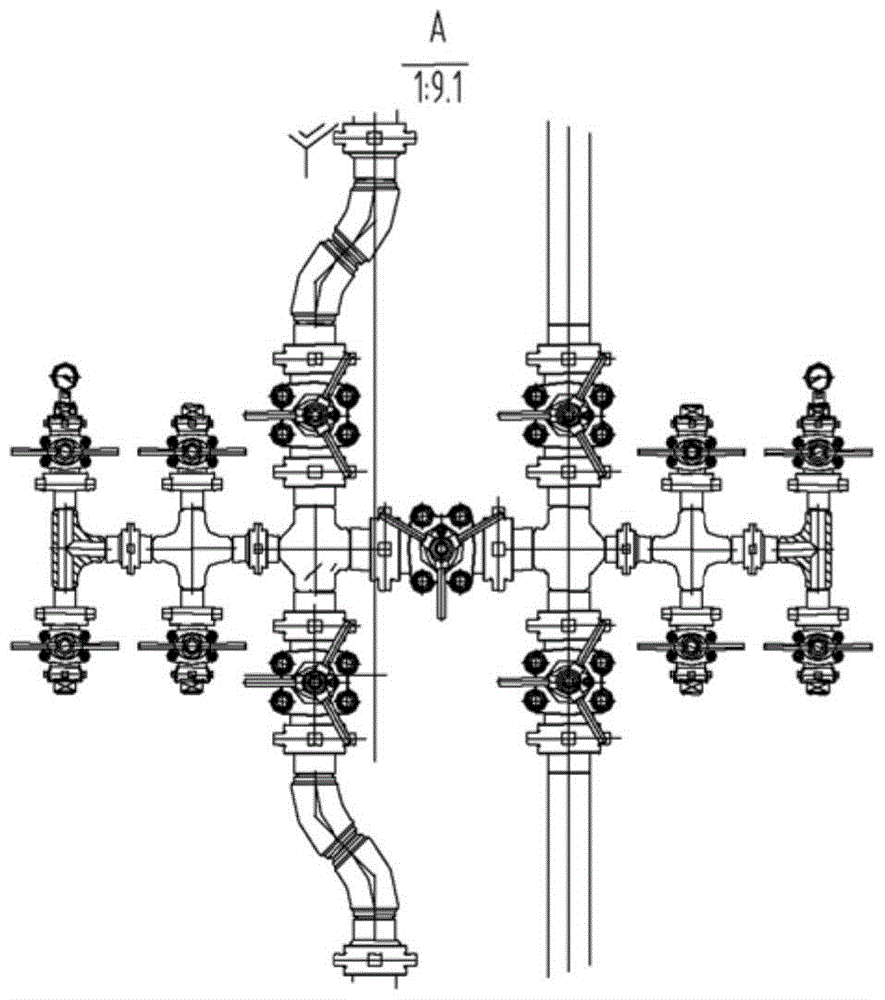

[0020] Attached below Figure 1-2 The drilling fluid circulation manifold structure of the present invention is described in detail.

[0021] A drilling fluid circulation manifold, which includes a gooseneck 1, a drill floor valve group 3, a drill floor valve group support 4, a standpipe 5, a drilling rig base clamp 7, a union 8, and a safety chain 9. The ground valve group 10, the mud pump pipe clamp 12, the automatic grouting control system and the pump pipeline; the gooseneck 1 has a rib plate, and there are hoisting holes on the rib plate, and the lengths of the two goosenecks are equal. Equipped with an extension nipple 2; the extension nipple 2 is connected to the riser 5; a drill floor valve group 3 is also arranged between the extension nipple 2 and the riser 5, and the drill floor The valve group 3 is arranged on the drill floor valve group bracket 4; the drill floor valve group 3 includes several three-way and four-way connections, and the three-way and four-way con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com