Clutch type formwork trolley, trolley assembly and underground passage concrete construction method

A formwork trolley and underground passage technology, which is applied in underground chambers, earthwork drilling, tunnels, etc., can solve the problems of high cost, long construction period, and overall demoulding of formwork trolleys, so as to save construction time and improve construction efficiency. Efficiency, the effect of achieving continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

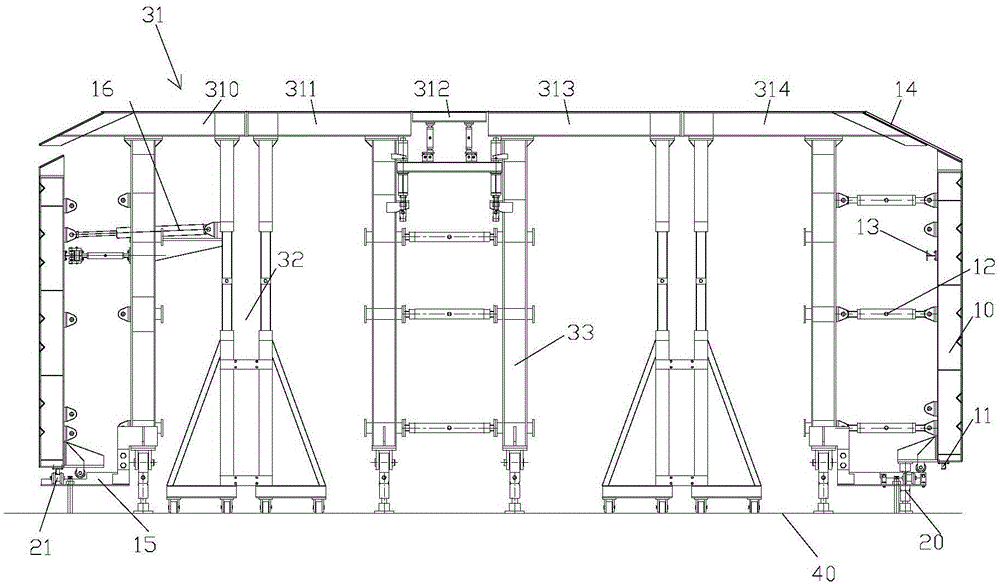

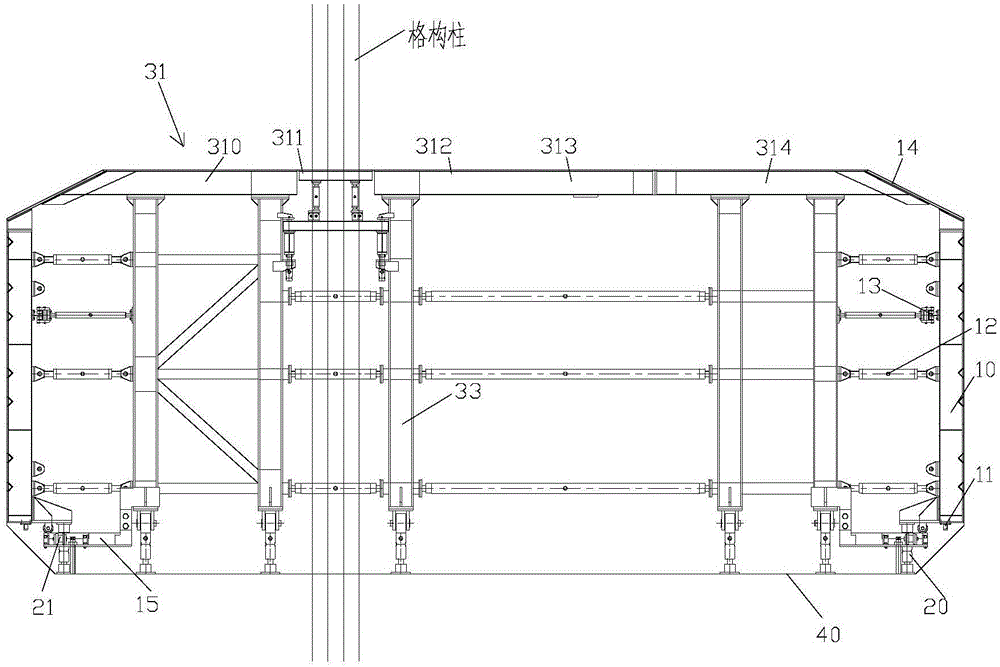

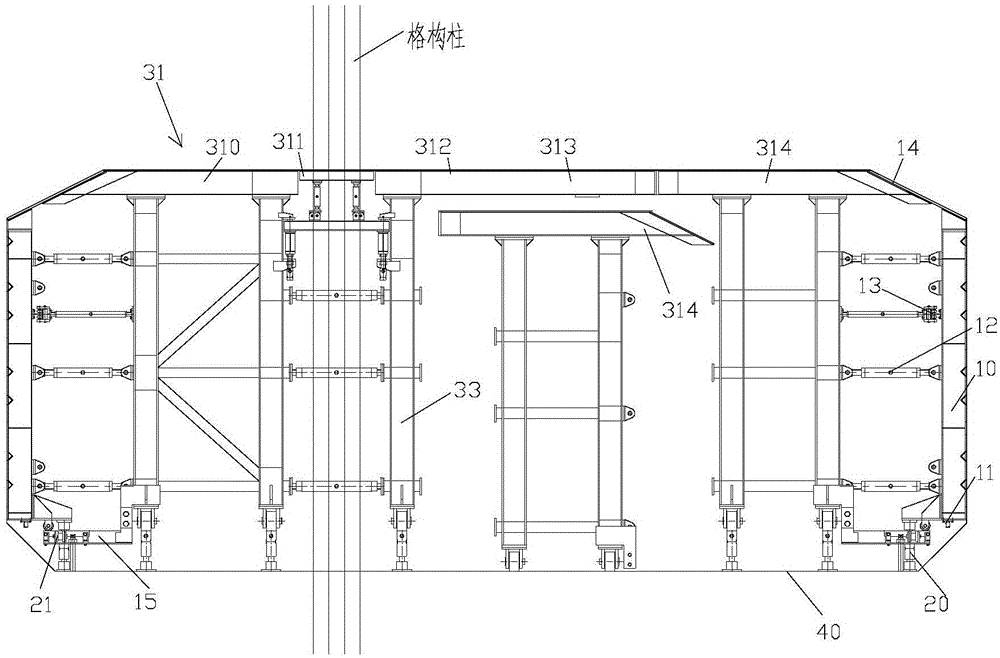

[0036] Combine below Figure 1 to Figure 5 Describe in detail the construction method of the clutch type formwork trolley, trolley assembly and underground passage concrete of the present invention.

[0037] Such as figure 1 As shown, a clutch-type formwork trolley is used for concrete pouring construction of underground passages, including a top formwork trolley 31, a side formwork trolley 10 and a vertical support bar 20, and the side formwork trolleys 10 are distributed on both sides of the top formwork trolley 31 and The wooden formwork 14 is connected with the top formwork trolley 31; the bottom of the side formwork 10 is provided with a moving guide rail 11, and the moving guide rail 11 cooperates with the moving pulley 21 arranged on the vertical support bar 20 to drive the side formwork 10 to move longitudinally.

[0038]The top formwork trolley 31 comprises at least two top formwork trolley units arranged side by side and connected by a detachable type, each top form...

Embodiment 3

[0046] Continue to combine below Figure 1 to Figure 5 Describe in detail the concrete construction method for the underpass. The concrete construction method of the underground passage divides the underground passage into several construction sections for continuous construction, including the following steps:

[0047] S001: Lay the bottom plate 40 of the underground passage, and place the trolley assembly on the bottom plate 40. The two trolley components are the top formwork trolley 1 and the top formwork trolley 2, so that the top formwork trolley 1 is located in the first construction section. Top formwork trolley 2 is located in the second construction section;

[0048] S002: Please continue to refer to figure 2 , pouring concrete in the first construction section to form the structural side walls and structural roof of the first construction section at one time;

[0049] S003: Please continue to refer to figure 1 , after the concrete strength of the structural side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com