Precombustion chamber system of large-displacement gas internal combustion engine

A gas internal combustion engine and pre-combustion chamber technology, applied in the field of pre-combustion chamber system, can solve problems such as unreliability, unstable ignition, complex structure, etc., and achieve the effects of prolonging service life, facilitating ignition, and good manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

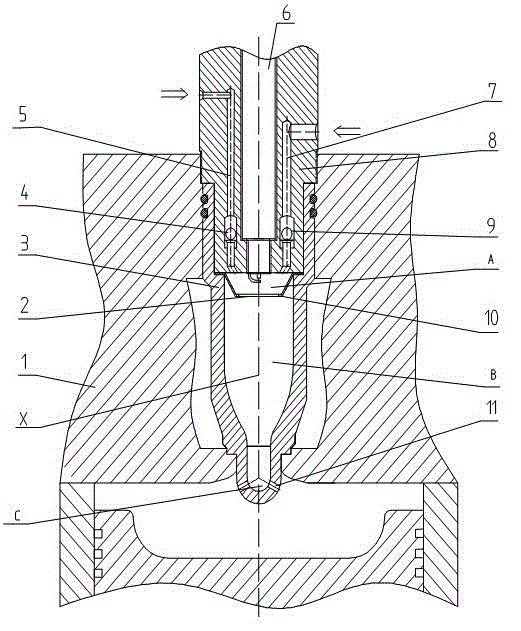

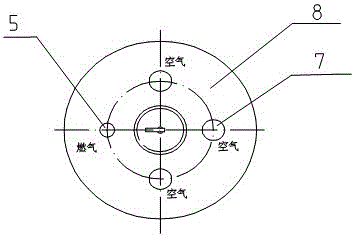

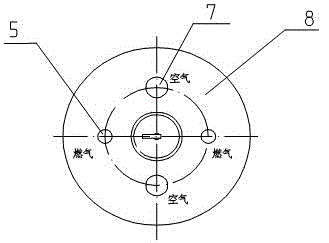

[0022] Such as figure 1 As shown, the present invention discloses a pre-chamber system of a large-displacement gas internal combustion engine, which includes a pre-chamber device vertically embedded and installed in the cylinder head 1 of the internal combustion engine. The pre-chamber device includes a pre-chamber 3 and a pre-chamber The ignition device above the chamber 3; the pre-combustion chamber 3 is a hollow structure with an open top. C has a nozzle 11 protruding from the lower end surface of the cylinder head 1 and for flame ejection; the ignition device includes a cylinder 8 placed on the top end surface of the pre-chamber 3 and a combustor built in the ignition area A of the pre-chamber 3 10. A spark plug 6 is embedded in the center of the cylinder 8, the spark plug 6 is extended along the long axis of the cylinder 8, and the gas inlet passage 5 extending to the bottom of the cylinder 8 and the air inlet are drilled on the side wall of the cylinder 8. Gas passage 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com