Laser dust sensor

A dust sensor and sensor technology, which is applied in scientific instruments, measuring devices, suspension and porous material analysis, etc., can solve the problems of increasing the resistance of the sampling system, reducing the sampling flow rate, and the large volume of the airflow flow sensor, etc., to achieve long-term reliability operation, good sensor accuracy, and the effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

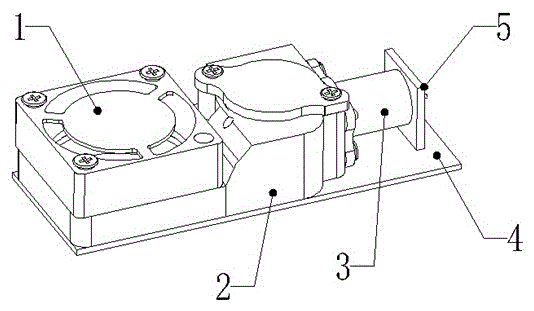

[0025] Such as figure 1 As shown, a laser dust sensor includes a fan 1, a detection cavity 2, a laser installation structure 3, a detection circuit board 4 with a photosensitive element microcontroller, and a laser 5.

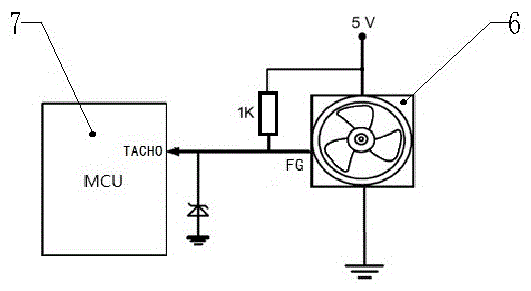

[0026] figure 2 A typical connection circuit principle of a single-chip microcomputer and a fan adopting the scheme of the present invention is shown. The fan 6 has an FG speed detection signal output, which is connected to the TACHO interface of the single-chip microcomputer MCU7. The single-chip microcomputer MCU7 collects the FG signal output by the fan 6 and uses the FG The signal corrects the sensor output in real time.

[0027] figure 2 The circuit in the circuit uses 5V DC to supply power to the fan 6. One wire of the fan 6 is connected to 5V, one wire is grounded, and the third wire is connected to the single-chip microcomputer MCU7. voltage diode.

[0028] The described real-time correction method is:

[0029] When the sensor is calibrated, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com