Electrostatic charge image developing toner

A technology for electrostatic charge images and toners, which can be applied to developers, electrographics, instruments, etc., can solve the problems of lack of charging stability and high moisture content, and achieve the effect of inhibiting durable deterioration and high charging stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0199] (1) Preparation of colorant particle dispersion

[0200] Add 11.5 parts by mass of n-dodecyl sodium sulfate to 160 parts by mass of ion-exchanged water, and slowly add 24.5 parts by mass of copper phthalocyanine while stirring the solution, and then use the stirring device "CLEARMIXWMOTIONCLM-0.8" (manufactured by MTechnique) Dispersion treatment was performed, thereby preparing a dispersion liquid of colorant fine particles having a volume-based median diameter of 126 nm. This was used as a colorant fine particle dispersion [C].

[0201] (2) Preparation of dispersion liquid of styrene acrylic resin particles

[0202] (step 1 aggregation)

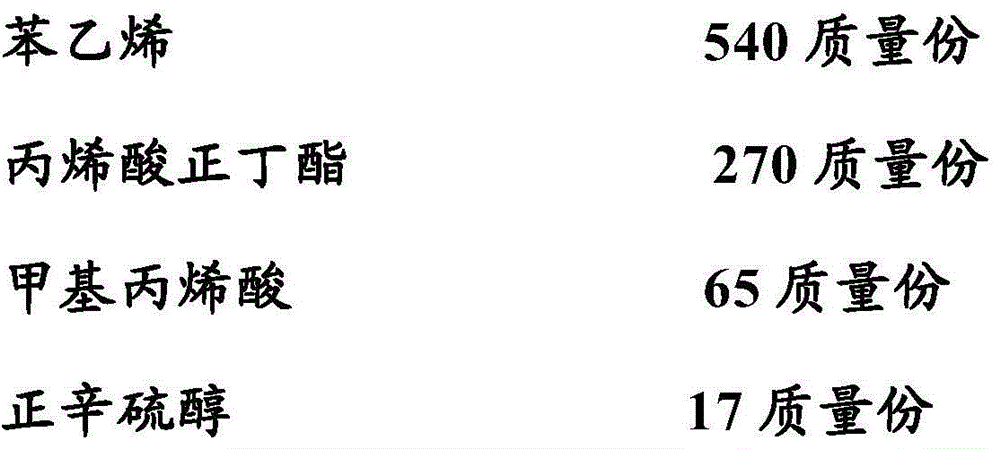

[0203] In a reaction vessel equipped with a stirring device, a temperature sensor, a temperature control device, a cooling pipe, and a nitrogen gas introduction device, 2.0 parts by mass of anionic surfactant "sodium lauryl sulfate" was dissolved in 2900 parts by mass of ion-exchanged water. The resulting anionic surfactant soluti...

manufacture example 2~3

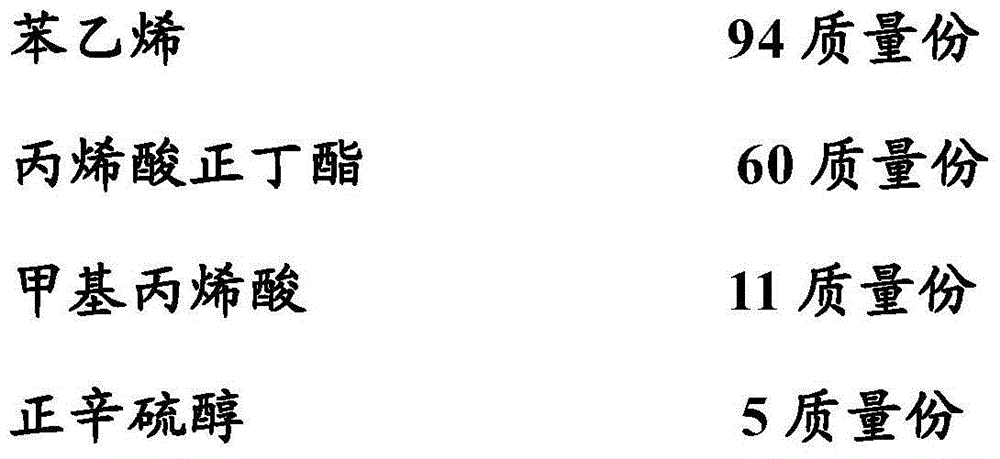

[0216] In Production Example 1 of Toner Matrix Particles (2) In the third polymerization step of preparation of a dispersion of styrene-acrylic resin particles, styrene (St) and acrylic acid constituting the monomer solution (3) were changed according to Table 1. Except for the formulation of n-butyl ester (BA) and methacrylic acid (MAA), prepare styrene acrylic resin microparticle dispersions [2] to [3] in the same manner, (3) Manufacturing process of toner matrix particles In , the toner matrix particles [2] to [3] were produced in the same manner except that the styrene acrylic resin fine particle dispersion [2] to [3] was used instead of the styrene acrylic resin fine particle dispersion [1].

[0217] [Table 1]

[0218] [Table 1]

[0219]

manufacture example 4

[0221] Production Example 1 of Toner Matrix Particles (3) In the production of toner matrix particles, the polyester resin microparticle dispersion [1] prepared as follows was used instead of the styrene acrylic resin microparticle dispersion [1], except In addition, toner matrix particles [4] were produced in the same manner.

[0222] -Preparation of dispersion liquid of polyester resin particles-

[0223] (1) Synthesis of polyester resin

[0224] In the reaction tank with cooling tube, mixer and nitrogen inlet pipe, add 360 mass parts of bisphenol A propylene oxide 2 molar adducts, 80 mass parts of terephthalic acid, 55 mass parts of fumaric acid and 2 Parts by mass of titanium tetraisopropoxide as a polycondensation catalyst were reacted at 200°C for 10 hours under a nitrogen stream while distilling off generated water. Next, the reaction was performed under a reduced pressure of 13.3 kPa (100 mmHg), and when the softening point reached 104° C., it was taken out to synthe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com