adhesive composition

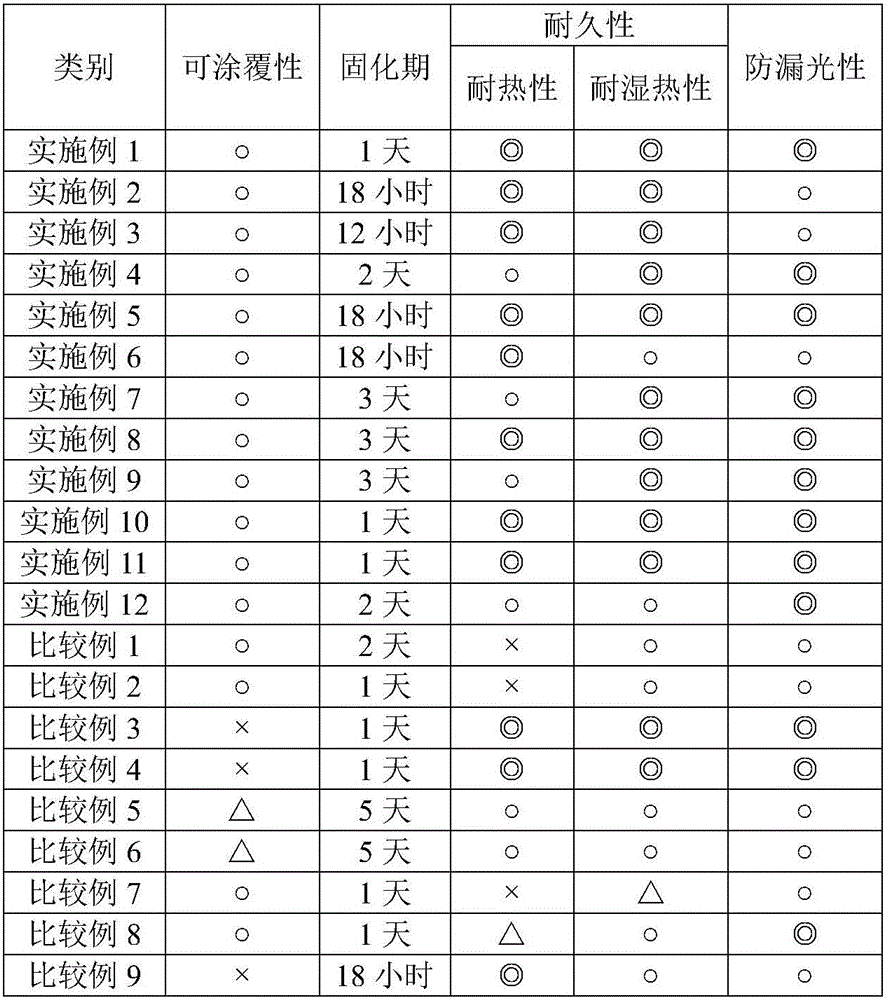

A composition and adhesive technology, applied in the direction of adhesive types, ester copolymer adhesives, adhesives, etc., can solve the problems of poor coatability, durability defects, decreased productivity, etc., and achieve the goal of inhibiting durability Effects of poor performance, excellent coatability, good productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of the copolymer is not particularly limited. The copolymer can be prepared by methods conventionally used in the art, such as bulk polymerization, solution polymerization, emulsion polymerization, and suspension polymerization. Among them, solution polymerization is preferable. In addition, solvents, polymerization initiators, chain transfer agents for controlling molecular weight, and the like conventionally used at the time of polymerization can be used.

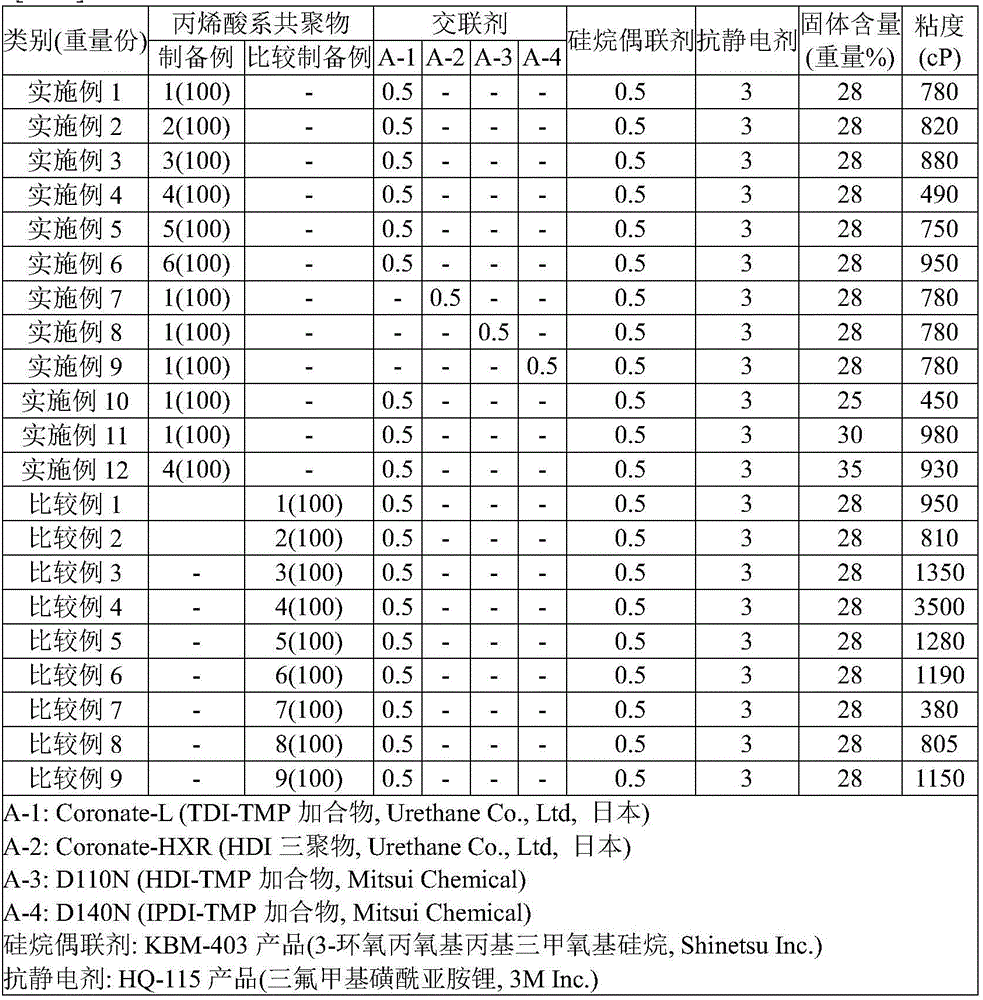

[0048] The acrylic adhesive composition of the present invention may further contain a crosslinking agent.

[0049] Crosslinkers improve adhesion and durability, and maintain the adhesive's high-temperature reliability and shape.

[0050] Examples of the cross-linking agent may include isocyanate-based cross-linking agents, epoxy-based cross-linking agents, melamine-based cross-linking agents, peroxide-based cross-linking agents, metal chelate-based cross-linking agents, and oxazoline-based...

preparation example 1

[0062] The monomers of 86 parts by weight of n-butyl acrylate (BA), 8 parts by weight of benzyl methacrylate (BzMA), 5 parts by weight of acrylic acid (AA) and 1 part by weight of 4-hydroxybutyl acrylate (4-HBA) The mixture was charged into a 1 L reactor equipped with a cooling device for promoting nitrogen reflux and controlling temperature, and then 100 parts by weight of ethyl acetate (EAc) as a solvent was charged thereinto. Thereafter, nitrogen was purged for 1 hour to remove oxygen, and then the temperature was maintained at 80°C. Stir the monomer mixture until smooth. Subsequently, 0.07 parts by weight of azobisisobutyronitrile (AIBN) was charged as a reaction initiator, followed by reaction for 8 hours, thereby preparing an acrylic copolymer (A-1) having a weight average molecular weight of about 800,000.

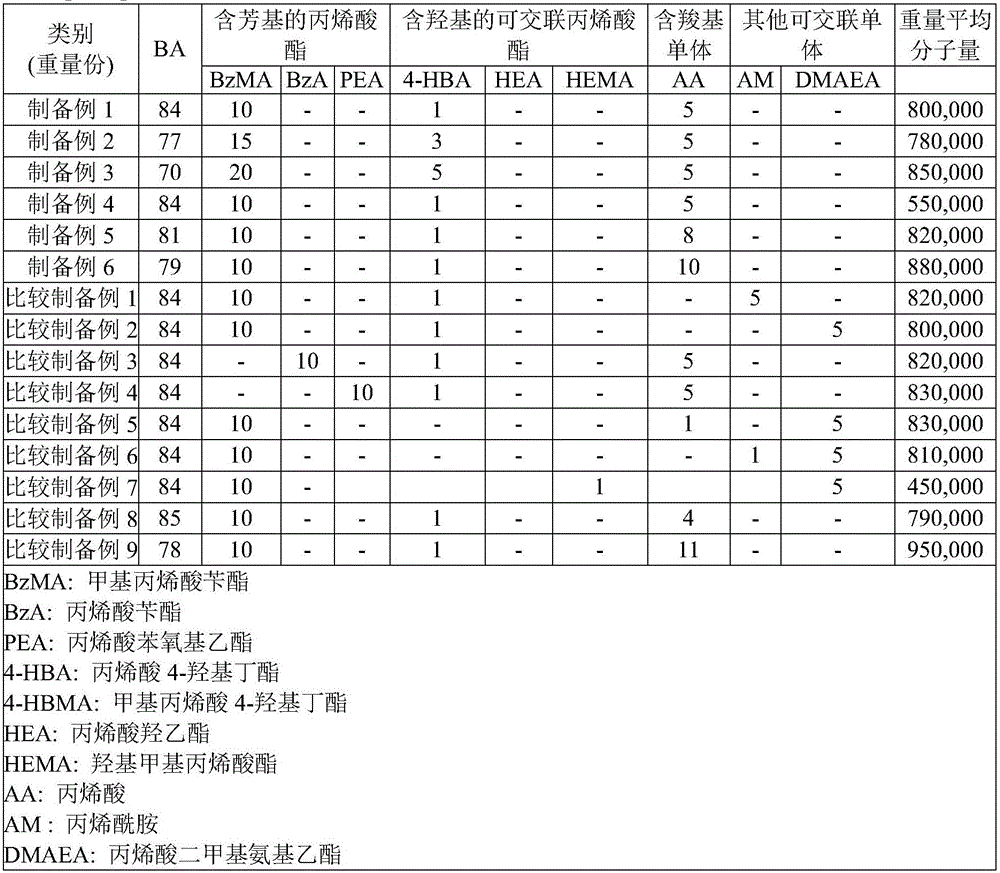

preparation example 2~6 and comparative preparation example 1~9

[0064] An acrylic copolymer was prepared in the same manner as Preparation Example 1, but using the monomer composition shown in Table 1 below.

[0065] Here, the following Preparation Example 4 was performed in the same manner as Preparation Example 1 except that 130 parts by weight of ethyl acetate (EA) was used. The following Preparation Example 7 was performed in the same manner as Preparation Example 1 except that 200 parts by weight of ethyl acetate (EA) was used and the temperature was kept at 90°C.

[0066] [Table 1]

[0067]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com