Colloidal dispersions comprising precious metal particles and acidic ionomer components and methods of their manufacture and use

A colloidal dispersion, precious metal technology, used in the field of electrodes and composite catalyst materials, the manufacture of ionomer layers, catalyst layers, and the composition of acidic ionomer compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

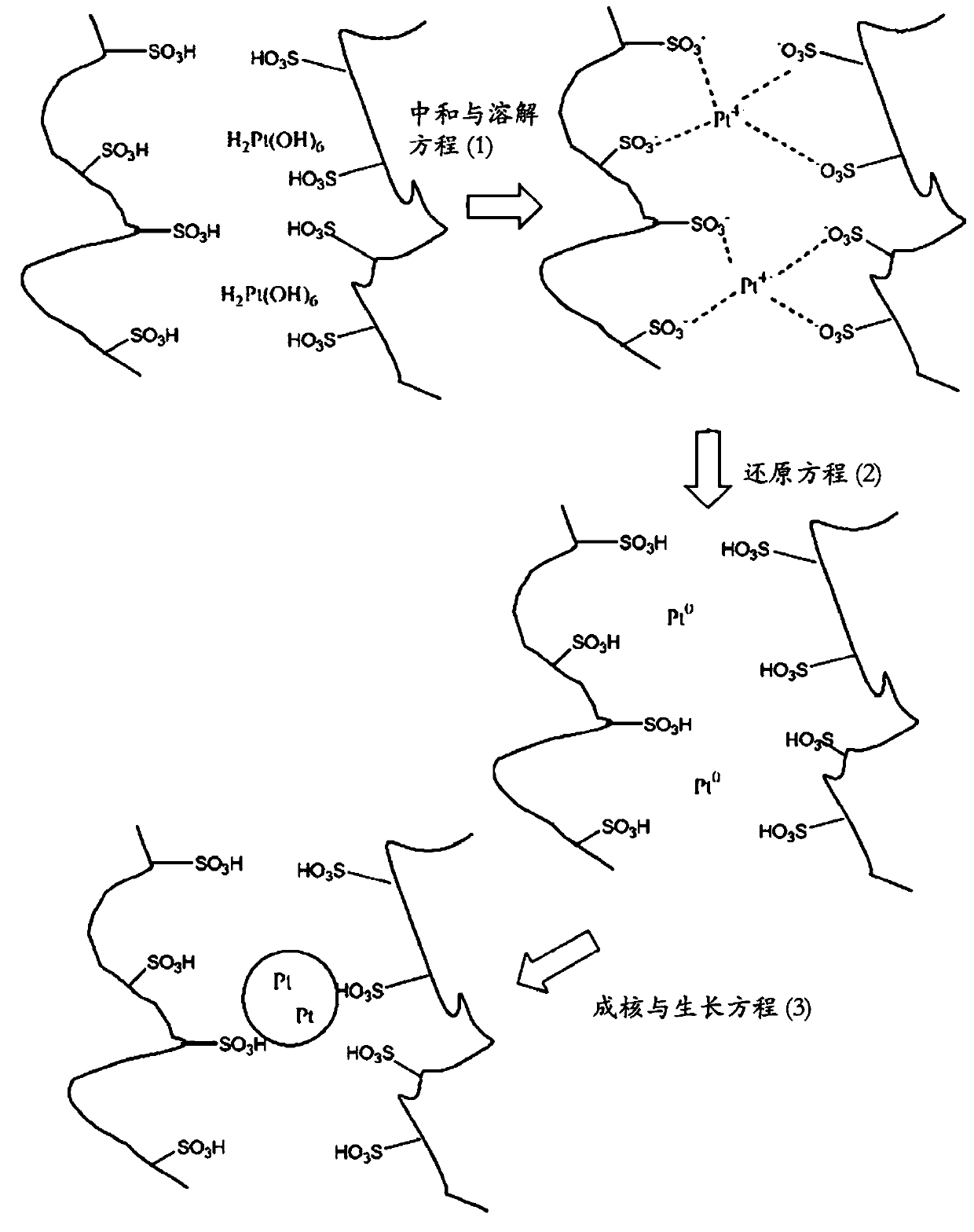

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0200] Preparation of composition (pre-product) containing Pt precursor compound and acidic ionomer

[0201] Dilute a water-based ionomer dispersion with deionized water D83-24B (from Solvay Specialty Polymers, Italy; 24% by weight ionomer; equivalent weight EW=830g / equivalent) in order to obtain an ionomer dispersion with the following composition:

[0202] 20% by weight solid ionomer

[0203] 80% by weight D.I. water

[0204] Charge 100 g of this ionomer dispersion into a 300 ml vessel. Subsequently, 375 g of grinding media (small Zr oxide beads) was added to the dispersion. Next, 1.06g platinum hexahydroxide (IV) acid H 2 Pt(OH) 6 (65% by weight Pt, Umicore AG & CoKG, Hanau / Germany) was added to the vessel and ground for 2 hours until the particle size of the Pt precursor compound reached the micron range. A yellow fluid composition was obtained, containing 0.68% by weight of Pt, 19.8% by weight of ionomer, and a Pt:ionomer ratio of 1:29.

example 2

[0206] Preparation of colloidal Pt / ionomer dispersion

[0207] A water-based ionomer dispersion D83-24B (from Solvay Specialty Polymers, Italy; 24% by weight ionomer; equivalent weight EW=830 g / equivalent) was concentrated by evaporation to obtain a 28.1% by weight ionomer dispersion in water. Add 1-propanol to this dispersion in order to obtain an ionomer dispersion with the following composition by mass:

[0208]

[0209] Charge 100 g of this ionomer dispersion into a 300 ml vessel. Subsequently, 375 g of grinding media (small Zr oxide beads) was added to the dispersion. Next, 1.06g platinum hexahydroxide (IV) acid H 2 Pt(OH) 6 (65% by weight Pt, Umicore Co., Ltd., Hanau / Germany) was added to the vessel and ground in a bead mill for 2 hours. The precursor compound is very well dispersed in the liquid ionomer, and the particles are in the micron range.

[0210] The obtained dispersion was stirred for 24 hours and reduced to produce a colloidal dispersion containing ionomer and ...

example 3

[0213] Preparation of colloidal Pt / ionomer dispersion

[0214] A water-based ionomer dispersion D83-24B (from Solvay Specialty Polymers, Italy; 24% by weight ionomer; equivalent weight EW=830 g / equivalent) was concentrated by evaporation to obtain a 28.1% by weight ionomer dispersion in water. Ethanol is added to this dispersion in order to obtain an ionomer dispersion having the following composition by mass:

[0215]

[0216] Charge 100 g of this ionomer dispersion into a 300 ml vessel. Subsequently, 375 g of grinding media (small Zr oxide beads) was added to the dispersion.

[0217] Next, 1.06g platinum hexahydroxide (IV) acid H 2 Pt(OH) 6 (65% by weight Pt, Umicore Co., Ltd., Hanau / Germany) was added to the vessel and ground in a bead mill for 2 hours. The precursor compound is very well dispersed in the liquid ionomer, and the particles are in the micron range.

[0218] The obtained dispersion was stirred for 24 hours and reduced to produce a colloidal dispersion containing i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water solubility | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com