Preparation method of high-quality fermented camel milk with function of auxiliarily lowering blood sugar

A technology of fermenting camel milk and lowering blood sugar, applied in the biological field, can solve the problems of no treatment for diabetes, only promotion of hypoglycemic effect, and failure to improve other functions of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

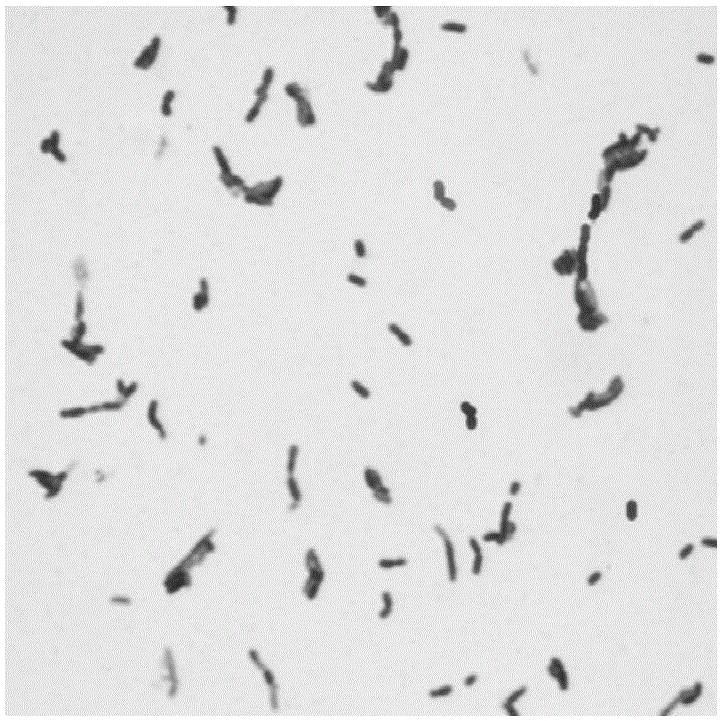

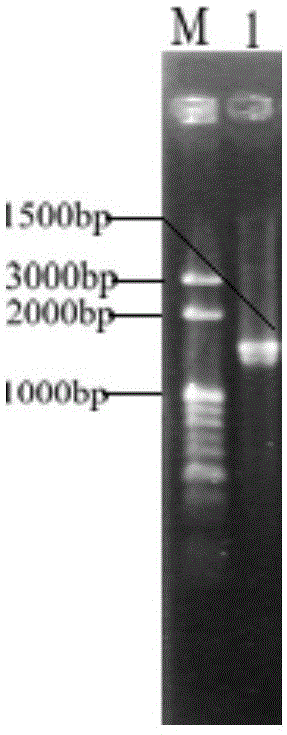

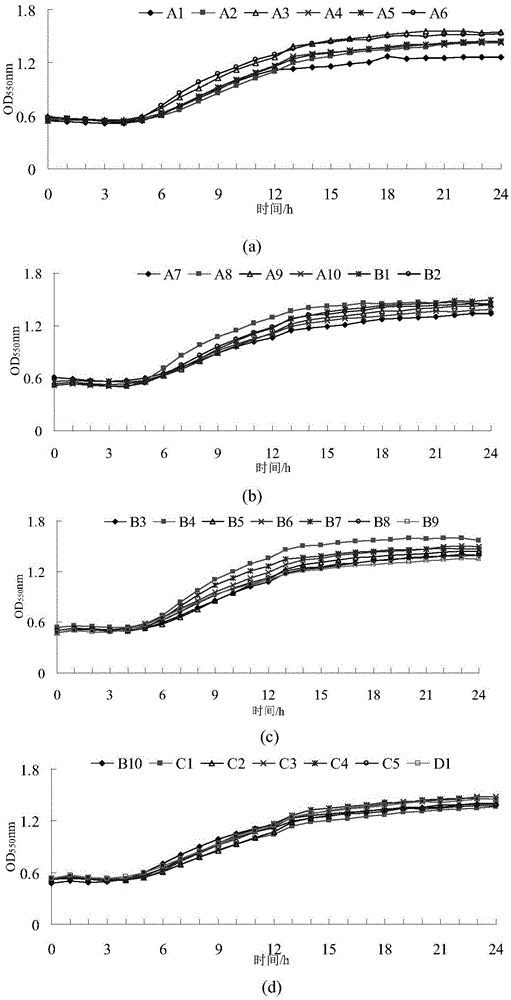

Method used

Image

Examples

Embodiment 1

[0156] 1000kg of fresh pure camel milk is standardized, preheated to 60°C, add 30kg of honey and 40kg of fructo-oligosaccharides, homogenize at 65°C, 20Mpa for 2min, after heat treatment at 65°C / 30min, cool to 42°C, press 3% (w / w) inoculation amount is inoculated starter, starter is made up of Lactobacillus plantarum grx16, Lactobacillus casei grx12, Lactobacillus delbrueckii subsp. bulgaricus grx33 and Lactobacillus fermentum grx07, and its ratio is 1:1:1: 1 (v / v), fermented at 42°C to curdled milk, and then refrigerated at 4°C for 24 hours to make fermented camel milk.

Embodiment 2

[0158] 1000kg of fresh pure camel milk is standardized, preheated to 55°C, add 40kg of honey and 30kg of fructo-oligosaccharide, homogenize at 65°C, 20Mpa for 2min, after heat treatment at 65°C / 30min, cool to 40°C, press 4% (w / w) inoculation amount is inoculated starter, starter is made up of Lactobacillus plantarum grx16, Lactobacillus casei grx12, Lactobacillus delbrueckii subsp. bulgaricus grx33 and Lactobacillus fermentum grx07, and its ratio is 1:1:1: 1 (v / v), fermented at 40°C to curdled milk, and then refrigerated at 4°C for 24 hours to make fermented camel milk.

Embodiment 3

[0160] 1000kg of fresh pure camel milk is standardized, preheated to 60°C, add 50kg of honey and 20kg of fructo-oligosaccharide, homogenize at 65°C, 20Mpa for 2min, after heat treatment at 65°C / 30min, cool to 37°C, press 6% (w / w) inoculation amount inoculates starter, and starter is made up of Lactobacillus plantarum grx16, Lactobacillus casei grx12, Lactobacillus delbrueckii subsp. bulgaricus grx33 and Lactobacillus fermentum grx07, and its ratio is 1:1:1: 1 (v / v), fermented at 37°C to curdled milk, and then refrigerated at 4°C for 24 hours to make fermented camel milk.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com