Large chicken cutlet coating flour and preparation method thereof

A technology for wrapping powder and chicken chop, which is applied to the field of wrapping powder for large chicken chop and its preparation, can solve problems such as uneven taste, and achieve the effects of enhancing, enriching and improving flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

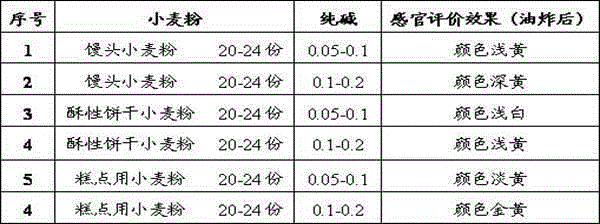

Image

Examples

Embodiment 1

[0028] Formula: 20 parts of wheat flour, 14 parts of wheat starch, 12 parts of corn starch, 20 parts of tapioca starch, 23 parts of tapioca granule powder, 1.5 parts of table salt, 0.5 parts of white sugar, 0.1 parts of soda ash, 0.1 parts of onion powder, 0.2 parts of garlic powder, Baking powder 0.6 part, guar gum 0.1 part.

[0029] The preparation method comprises the following steps:

[0030] (1) Preparation of white sugar powder:

[0031] Put the white granulated sugar into a grinder for crushing, and pass through a 40-mesh sieve to obtain white sugar powder;

[0032] (2) Preparation of premix 1:

[0033] Put the white sugar powder obtained in (1) into the mixer according to the mass ratio of salt, soda ash, garlic powder, onion powder, baking powder, and guar gum, and mix well to obtain premix 1 for later use;

[0034] (3) Premix 2 preparation:

[0035] Take wheat flour, wheat starch, corn starch and tapioca starch according to the mass ratio and put them into the mi...

Embodiment 2

[0043] Formula: 24 parts of wheat flour, 18 parts of wheat starch, 16 parts of corn starch, 26 parts of tapioca starch, 25 parts of tapioca granule powder, 2 parts of table salt, 0.8 parts of white sugar, 0.2 parts of soda ash, 0.2 parts of onion powder, 0.3 parts of garlic powder, Baking powder 0.8 part, guar gum 0.3 part.

[0044] The preparation method comprises the following steps:

[0045] (1) Preparation of white sugar powder:

[0046] Put the white granulated sugar into a grinder for crushing, and pass through a 40-mesh sieve to obtain white sugar powder;

[0047] (2) Preparation of premix 1:

[0048] Put the white sugar powder obtained in (1) into the mixer according to the mass ratio of salt, soda ash, garlic powder, onion powder, baking powder, and guar gum, and mix well to obtain premix 1 for later use;

[0049] (3) Premix 2 preparation:

[0050] Take wheat flour, wheat starch, corn starch and tapioca starch according to the mass ratio and put them into the mixe...

Embodiment 3

[0058]Formula: 22 parts of wheat flour, 16 parts of wheat starch, 14 parts of corn starch, 23 parts of tapioca starch, 27 parts of tapioca granule powder, 1.5 parts of table salt, 0.5 parts of white sugar, 0.1 part of soda ash, 0.1 part of onion powder, 0.3 part of garlic powder, Baking powder 0.7 part, guar gum 0.2 part.

[0059] The preparation method comprises the following steps:

[0060] (1) Preparation of white sugar powder:

[0061] Put the white granulated sugar into a grinder for crushing, and pass through a 40-mesh sieve to obtain white sugar powder;

[0062] (2) Preparation of premix 1:

[0063] Put the white sugar powder obtained in (1) into the mixer according to the mass ratio of salt, soda ash, garlic powder, onion powder, baking powder, and guar gum, and mix well to obtain premix 1 for later use;

[0064] (3) Premix 2 preparation:

[0065] Take wheat flour, wheat starch, corn starch and tapioca starch according to the mass ratio and put them into the mixer,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com