Chaenomeles speciosa biscuit and preparation method thereof

A technology of Papaya and Papaya, applied in baking, baked goods with modified ingredients, dough processing, etc., can solve the problems of inability to be used as fresh fruit, hard texture, etc., so as to improve the efficacy value and improve the comprehensive Quality, effect to enhance characteristic aroma and color quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

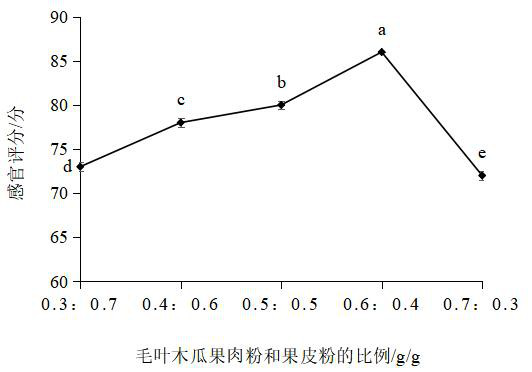

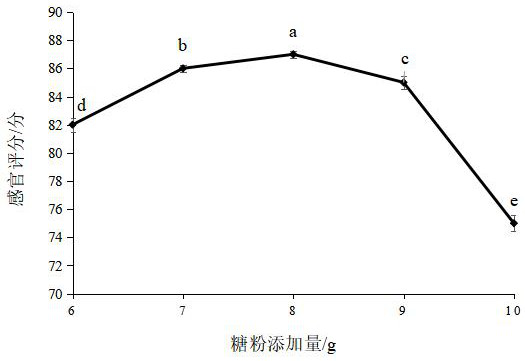

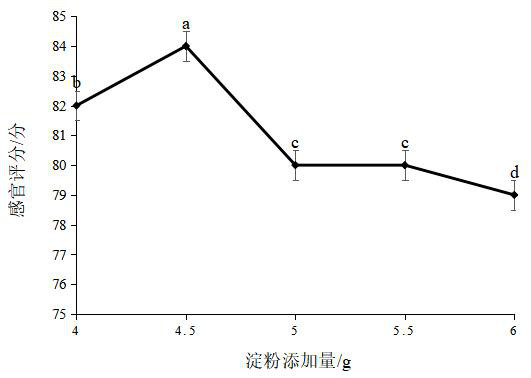

[0036] A papaya biscuit made from the following raw materials: 100 parts of low-gluten flour, 20 parts of sweet potato starch, 30 parts of powdered sugar, 55 parts of vegetable oil, 3 parts of papaya pulp powder, and 2 parts of papaya peel powder;

[0037] The preparation method of the above-mentioned papaya biscuit comprises the following steps:

[0038] (1) Cleaning of papaya fruit: select fresh and intact papaya fruit, wash with water, and drain;

[0039] (2) Separation of peel and pulp: Use a peeler to peel off the peel of papaya tomentosa with a thickness of about 2 mm, and collect the peel and pulp separately.

[0040] (3) Pulp slices: Cut the pulp into thin slices of about 3 mm.

[0041] (4) Color protection: quickly soak the sliced peel and pulp in the color protection solution, which is composed of 0.5% sodium chloride, 0.4% ascorbic acid, 0.2% L-cysteine and 0.8% citric acid. The balance is water.

[0042] (5) Drying: spread the pulp and peel of papaya papaya ...

Embodiment 2

[0050] A papaya biscuit made from the following raw materials: 100 parts of low-gluten flour, 22.5 parts of sweet potato starch, 40 parts of powdered sugar, 60 parts of vegetable oil, 3 parts of papaya pulp powder, and 2 parts of papaya peel powder;

[0051] Its preparation process is identical with embodiment 1.

Embodiment 3

[0053] A papaya biscuit made from the following raw materials: 100 parts of low-gluten flour, 25 parts of sweet potato starch, 45 parts of powdered sugar, 65 parts of vegetable oil, 1.5 parts of papaya pulp powder, and 3 parts of papaya peel powder;

[0054] Its preparation process is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com