Preparation method of deep-fry corn food product

A production method and corn technology, applied in food preparation, food science, application, etc., can solve the problems of extensive processing, poor palatability, and ordinary appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

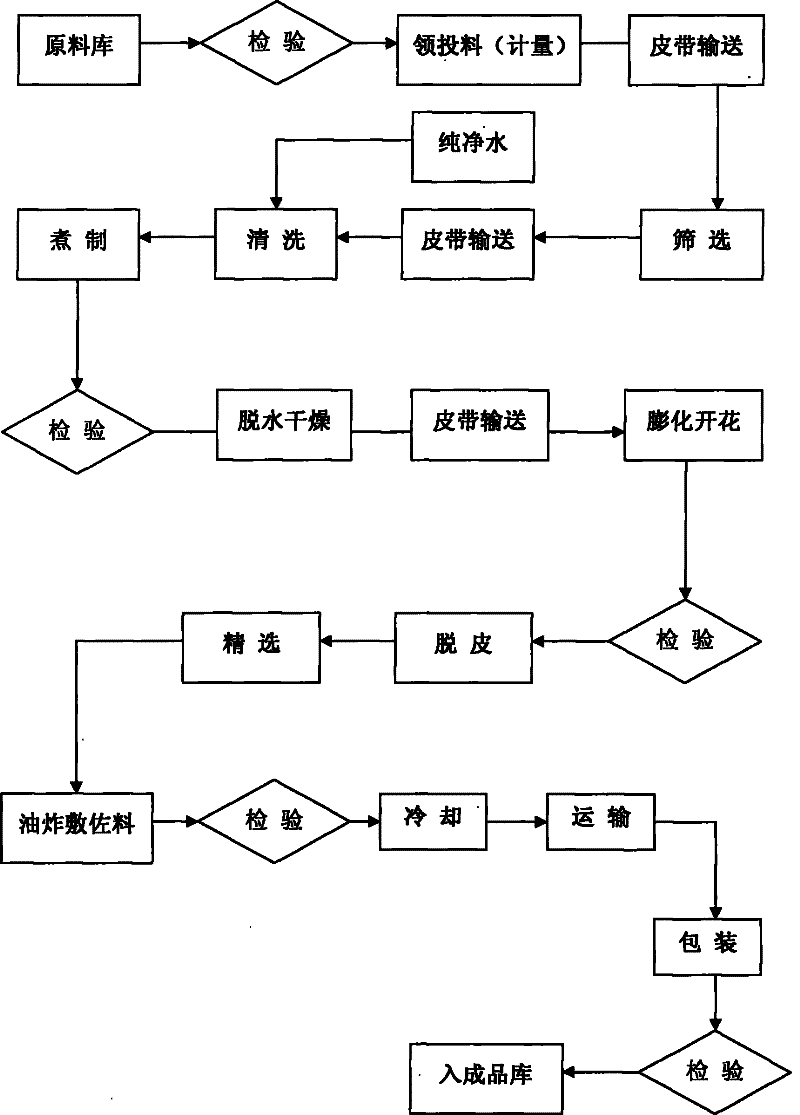

Image

Examples

Embodiment 1

[0020] Choose corn with full grains and bright color as raw material, rinse with pure water to remove surface dust and impurities, and filter dry; put corn and pure water in a steam pot at a weight ratio of 6:22 for cooking, and the steam pressure in the pot is controlled at 0.5 About MP, the cooking time is 180min.

[0021] Use an energy-saving dryer to dry the corn until the moisture content is about 10%, and the drying temperature is controlled at 80°C. Use a screening machine to further remove dust and impurities; after drying and screening, add corn at a volume ratio of 1:0.08. Wet the water evenly, pour it into the air-flow grain extruder after 15 minutes, tighten the cover and start heating, control the firepower evenly, and implement rapid expansion when the internal pressure of the grain extruder reaches 0.9 atmospheric pressure, so that the corn puffs and blooms.

[0022] Put the puffed and flowering corn into the peeling machine and rub it to make the skin fall off,...

Embodiment 2

[0024] Choose corn with full grains and bright color as raw material, rinse with pure water to remove dust and impurities, and filter dry; put corn and pure water in a steam pot at a weight ratio of 5:21 to cook, and the steam pressure in the pot is controlled at 0.6MP. The preparation time is 150min.

[0025] Use an energy-saving dryer to dry the corn to a moisture content of 10%, control the temperature at 90°C, and use a screening machine to further remove dust and impurities; after drying and screening, add clean water to wet the corn at a volume ratio of 1:0.08 Evenly, after 15 minutes, pour it into the air-flow grain extruder, tighten the lid and start heating, the firepower should be even, and implement rapid expansion when the pressure in the grain extruder reaches 1.0 atmosphere.

[0026] Put the puffed and flowering corn into the peeling machine and rub it to make the skin fall off, and then pass through the screening machine to remove the corn husk and impurities; p...

Embodiment 3

[0028] Choose corn with full grains and bright color as raw material, rinse with pure water to remove dust and impurities, and filter dry; put corn and pure water in a steam pot with a weight ratio of 6:23 to cook, and the steam pressure in the pot is controlled at 0.6MP. The preparation time is 150min.

[0029] Use an energy-saving dryer to dry the corn until the moisture content is 10%, and the temperature is controlled at 100°C. Use a screening machine to further remove dust and impurities; after drying and screening, add clean water to wet the corn at a volume ratio of 1:0.08 Evenly, after 15 minutes, pour it into the air-flow grain extruder, tighten the lid and start heating, the firepower should be even, and implement rapid expansion when the pressure in the grain extruder reaches 1.0 atmosphere.

[0030] Put the puffed and flowering corn into the peeling machine and rub it to make the skin fall off, and then pass through the screening machine to remove the corn husk and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com