Linseed dehulling method

A flaxseed, grading and screening technology, applied in the fields of shelling, pod removal, food science, etc., can solve the needs of deep processing of backward agricultural products, the difficulty of peeling and separation, and the low technical maturity, and achieve good nutritional value and equipment. Simple and easy operation, high separation of shell and kernel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1 process optimization experiment

[0043] 1. Aperture optimization experiment of vibrating screen in classification screening pretreatment:

[0044] In the pretreatment of grading and screening, flax seeds need to pass through a vibrating sieve, and the linseed is divided into three grades: large, medium and small according to the particle size.

[0045] Therefore, this experiment set up 16 groups of experimental groups, each group of flaxseed 90g, passed through a vibrating sieve respectively, and then screened the undersize of the first-level sieve through the second-level sieve, and screened the first-level and second-level sieves respectively. Weighed, the results are as follows:

[0046] Primary sieve aperture (mm)

4

3.5

3

2.5

Amount of sieve (g)

5.6

10.5

28.9

36.8

[0047] 2) After the secondary sieve, the amount of sieve material is as follows:

[0048] Secondary sieve aperture

2mm...

Embodiment 2

[0056] According to the flaxseed shelling method of the present invention, carry out flaxseed shelling according to the following steps:

[0057] (1) Grading and screening pretreatment:

[0058] Utilize the first vibrating sieve of 3mm aperture to carry out the first classification and screening of flaxseed, so that obtain the first sieve and the first undersize respectively, wherein the first sieve is the first grade flaxseed; Utilize 2mm aperture The second vibrating sieve carries out the second classification and screening of the first undersize, so as to obtain the second oversize and the second undersize respectively, wherein the second oversize is second-grade linseed, and the second oversize is linseed. The undersieve is the third grade flaxseed.

[0059] Then, for each grade of flaxseed, the following steps are carried out in sequence:

[0060] (2) Sectional microwave drying treatment:

[0061] Put the linseed into the microwave dryer, keep the power of the microwav...

Embodiment 3

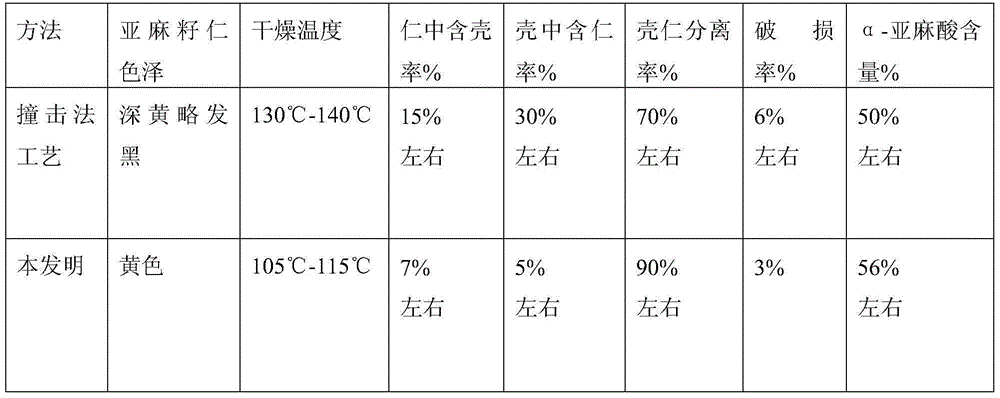

[0072] From these aspects of linseed kernel color and luster, drying temperature, kernel husk content rate, husk kernel content rate, husk kernel separation rate, linseed damage rate and α-linolenic acid content, the present invention shown in embodiment 2 The linseed dehulling method is compared with the traditional impact method, and the results are shown in the table below:

[0073]

[0074] Wherein, the above-mentioned traditional percussion method process is carried out by adopting the optimal parameters selected in the following documents:

[0075] Liang Xia et al. Research on key technologies of flaxseed peeling [J]. Agricultural Products Processing Journal, 2007, (1): 18-19, 39. The full text of which is incorporated herein by reference.

[0076] From the results shown in the table above, it can be seen that:

[0077] When using the method of the present invention to dehull the linseed, the color of the linseed kernel, the drying temperature, the percentage of shel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com