Hypoglycemic composition and application thereof

A composition and hypoglycemic technology, applied in the directions of drug combination, heavy metal compound active ingredient, application, etc., can solve the problems of increased cost, increased sensitivity of pancreatic islet receptors, large dose, etc., and achieve the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

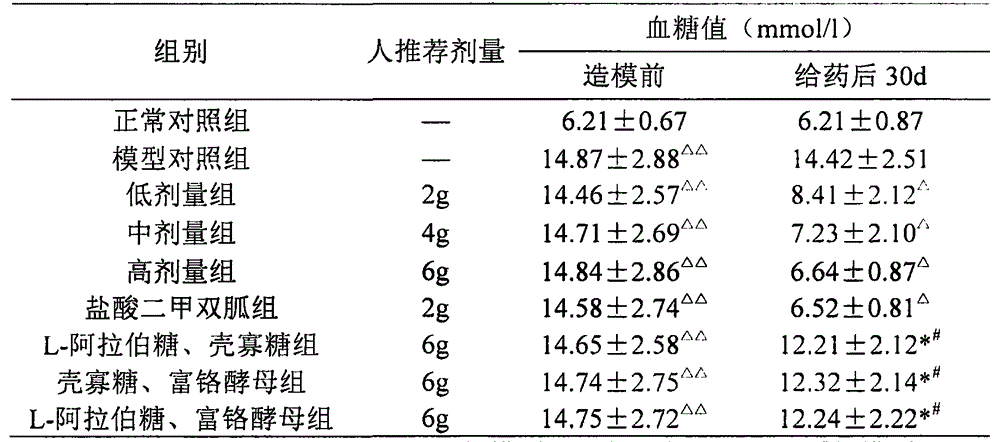

Embodiment 1

[0042] Raw materials: L-arabinose 3340g, chitooligosaccharides 660g, chromium-rich yeast 160g (containing 0.32g trivalent chromium), accessories: starch 340g

[0043] The L-arabinose is crushed and passed through an 80-mesh sieve; the chitosan, chromium-rich yeast, and starch are respectively passed through an 80-mesh sieve for use. The chromium-rich yeast and oligochitosan are mixed uniformly, and then mixed with L-arabinose and starch in a mixer for 30 minutes to obtain a mixed powder for use. Add 80% ethanol to the above mixed powder and stir to prepare soft material, granulate with 20 mesh, dry at 50-60 DEG C, and granulate with 20 mesh to obtain granules. Fill the particles with 0.45 g / capsule, and polish and screen the obtained capsules, and reject the unqualified products to obtain qualified capsules.

Embodiment 2

[0045] Raw materials: 5010g of L-arabinose, 990g of chitooligosaccharides, 240g of chromium-rich yeast (containing 0.48g of trivalent chromium), auxiliary materials: 3760g of mannitol.

[0046] The L-arabinose is crushed and passed through an 80-mesh sieve; the chitosan oligosaccharide, chromium-rich yeast, and mannitol are respectively passed through an 80-mesh sieve for use. The chromium-rich yeast and the chitosan oligosaccharide are mixed uniformly, and then mixed with L-arabinose and mannitol in a mixer for 30 minutes to obtain a mixed powder for use. Divide the mixed powder into 2g / bag. Immediately.

Embodiment 3

[0048] Raw materials: 2400g of L-arabinose, 480g of chitooligosaccharides, 120g of chromium-rich yeast (containing 0.24g of trivalent chromium), 1752g of mannitol, auxiliary materials: 48g of magnesium stearate.

[0049] The L-arabinose is crushed and passed through an 80-mesh sieve; the chitosan, chromium-rich yeast, mannitol, and magnesium stearate are respectively passed through an 80-mesh sieve. The chromium-rich yeast and the chitosan oligosaccharide are mixed uniformly, and then mixed with L-arabinose and mannitol in a mixer for 30 minutes to obtain a mixed powder. Add 30% ethanol to the above mixed powder and stir to make a soft material, 20 mesh Granules are dried at 40-50°C to a moisture content of 3.0-5.0%, 24 meshes are granulated to obtain dry granules. Put the dry granules and magnesium stearate into a mixer and mix for 10 minutes, mix evenly, to obtain the total mixed granules. The total mixed granules are pressed into tablets, 1g / tablet, to obtain chewable tablets...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com