VOCs treatment method and device

A waste gas treatment and waste gas technology, which is applied in separation methods, chemical instruments and methods, air quality improvement, etc., can solve the problems of non-standard discharge, limited use range, high initial investment and maintenance costs, water vapor sensitivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A VOCs exhaust gas treatment method described in Embodiment 1 of the present invention, comprising:

[0047] The VOCs waste gas is collected into the micro-nano bubble purification tower 1, and the micro-nano bubble purification tower 1 washes and disperses the VOCs waste gas, and the removed VOCs waste gas enters the circulation pool 6;

[0048] VOCs exhaust gas enters the microbial purification tower 8 from the gas outlet of the micro-nano bubble purification tower 1, and the microbial purification tower 8 absorbs and decomposes the VOCs exhaust gas, and the decomposed metabolites enter the circulation pool 13;

[0049] VOCs exhaust gas is discharged from the chimney 16 through the induced draft fan 15;

[0050] The circulating fluid purification and reuse device 17 purifies the impurities and metabolites produced in the circulating pool 6 and the circulating pool 13 respectively.

Embodiment 2

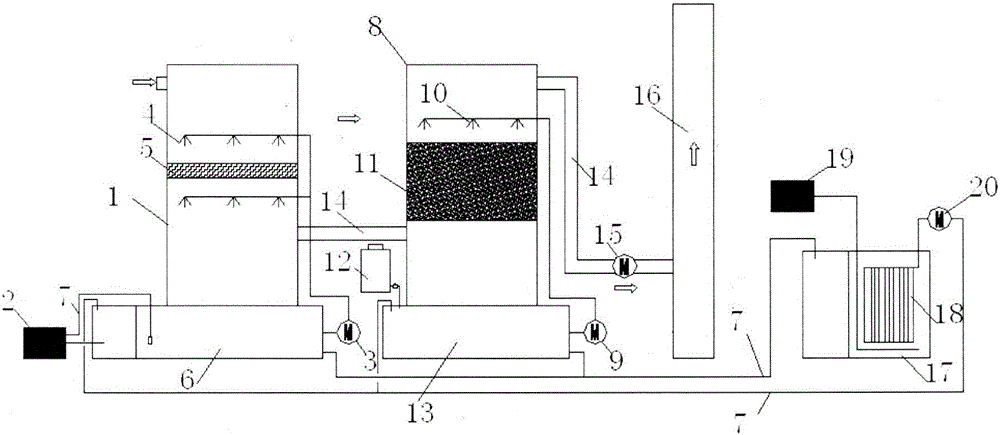

[0052] like figure 1 As shown, it is a VOCs exhaust gas treatment device described in the embodiment of the present invention, including: a micro-nano bubble purification tower 1, a microbial purification tower 8, an induced draft fan 15, a chimney 16, and a circulating fluid purification and recycling device 17;

[0053] In this embodiment, the micro-nano bubble purification tower 1 is provided with an air inlet, a spray device 4, a mixed cutting layer 5, a spray device 4, and an air outlet from top to bottom; the bottom of the micro-nano bubble purification tower 1 A circulation pool 6 communicating with the micro-nano bubble purification tower 1 is provided;

[0054] In the microbial purification tower 8, an air outlet, a leaching device 10, a biological filter material 11, and an air inlet are sequentially arranged from top to bottom; the bottom of the microbial purification tower 8 is provided with a circulation pool 13 that communicates with the microbial purification to...

Embodiment 3

[0064] like figure 1 As shown, it is a VOCs exhaust gas treatment device in this application example, and the specific process is:

[0065] There is a VOCs waste gas inlet on the micro-nano bubble purification tower 1. After entering the micro-nano bubble purification tower 1, the VOCs waste gas flows from the top down. First, it is washed and pre-wetted by the upper spray system 4, and then installed in the purification tower The mixed cutting layer 5 in the middle is fully dispersed and mixed with the micro-nano-bubble circulating liquid of the lower spray device 4, and the impurities and VOCs pollutants in the exhaust gas are washed, removed and absorbed, and the down-flowing circulating liquid enters the bottom of the micro-nano-bubble purification tower 1 The circulation pool 6, and the external micro-nano bubble generator 2 continuously injects micro-nano bubbles into the circulation pool 6 through the pipeline, and the micro-nano bubble mixture is pumped by the external...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com