Multi-wire sawing machine roller for cutting SiC single crystals with different diameters and use method of multi-wire sawing machine roller

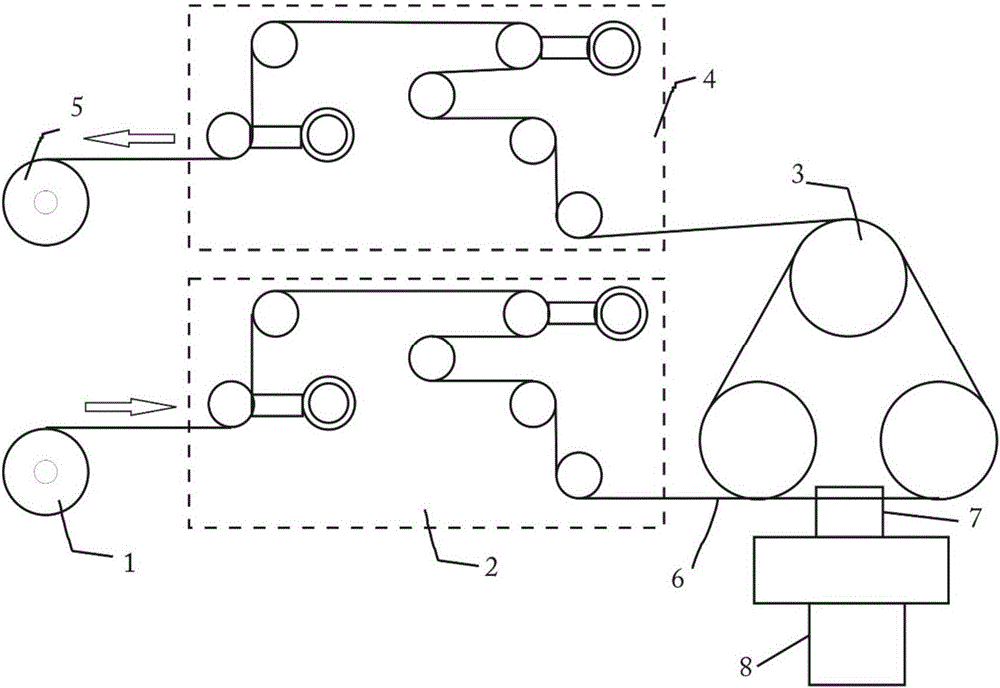

A multi-wire cutting machine and metal cutting wire technology, which is applied to fine working devices, manufacturing tools, stone processing equipment, etc., can solve the problems of not being able to cut SiC single crystals at the same time, reduce cutting efficiency, and cumbersome operation steps, and achieve saving Reduce manpower, improve cutting efficiency, and reduce the effect of operating procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

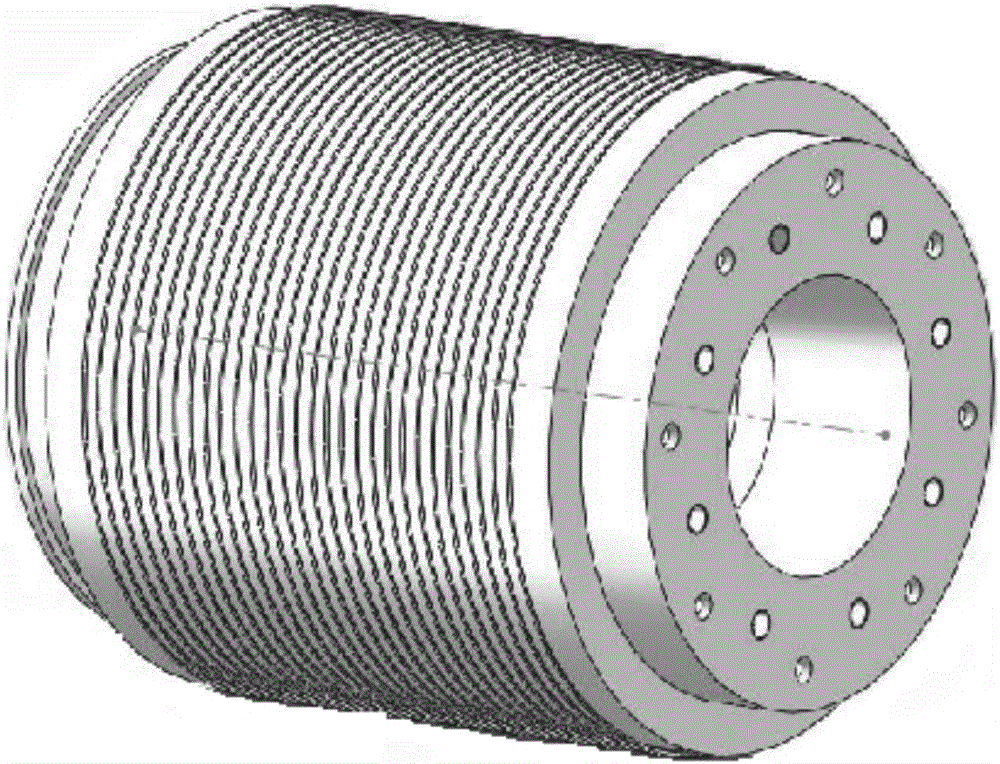

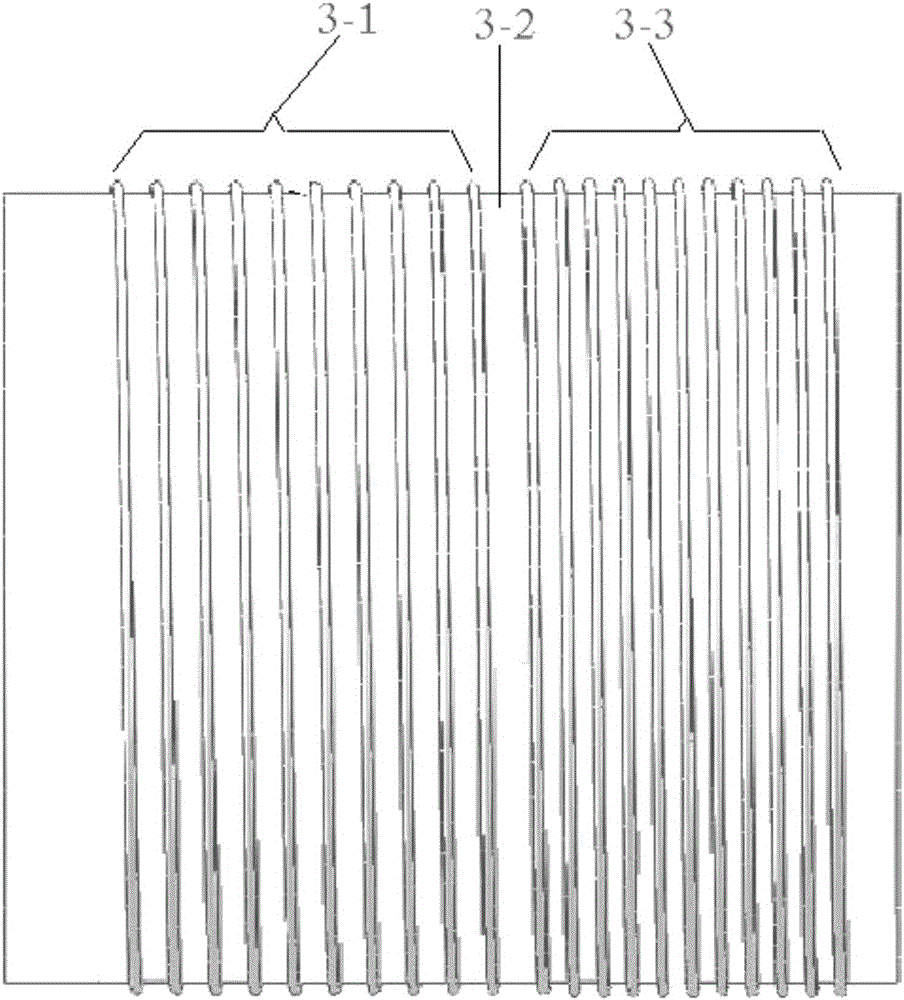

[0049]A multi-wire cutting machine roller 3 for realizing cutting of SiC single crystals with different diameters, the roller 3 is provided with a first groove section 3-1 and a second groove section 3-3, and each groove section is provided with V-shaped grooves at equal intervals , the material of the roller 3 is polyethylene material, the slotting angle of the V-shaped groove is 50°, the slot spacing of the first slot section 3-1 is 0.73mm, the slot spacing of the second slot section 3-3 is 0.85mm, the slot A transition groove 3-2 is provided between the intervals, and the width of the transition groove 3-2 is 1.5 mm. The purpose of the transition groove 3-2 is to prevent edge chipping when the roller 3 is grooved.

[0050] In this embodiment, the effective length of the roller 3 is 260mm, and 5mm is reserved at both ends of the roller. The metal cutting wire 6 has a diameter of 0.16 mm.

[0051] This embodiment operates as follows:

[0052] (1) Roller installation:

[0...

Embodiment 2

[0063] As described in Example 1, the difference is:

[0064] The material of the roller 3 is polyurethane material, and the slotting angle is 70°. The roller 3 is provided with three groove intervals of 0.6mm, 0.8mm, and 0.9mm respectively. The crystals to be cut are 3inchSiC single crystal, 4inchSiC single crystal and 6inchSiC For single crystal, the corresponding crystal thicknesses are 20mm, 15mm, and 10mm respectively; the width of the transition groove 3-2 is 1.0mm.

[0065] According to the steps in Example 1, wires were wound in slot intervals with slot spacings of 0.6 mm, 0.8 mm, and 0.9 mm, and the winding widths were 22 mm, 16 mm, and 12 mm, respectively. According to the final sheet thickness requirements, place 3inch SiC single crystals, 4inch SiC single crystals and 6inch SiC single crystals directly below the intervals of 0.6mm, 0.8mm and 0.9mm roller grooves respectively, and fix them on the workbench. Graphite flakes are placed between them, the position of t...

Embodiment 3

[0068] As described in Example 1, the difference is:

[0069] Roller 3 is provided with four groove intervals of 0.65mm, 0.78mm, 0.86 and 0.98mm respectively, and the corresponding crystals to be cut are 2inchSiC single crystal, 3inchSiC single crystal, 4inchSiC single crystal and 6inchSiC single crystal, and the corresponding thicknesses are 18mm respectively , 16mm, 14mm and 13mm. The transition groove 3-2 has a width of 1.3mm. According to the steps in Example 1, wires were respectively wound on the groove intervals of 0.65mm, 0.78mm, 0.86mm and 0.98mm of the roller, and the winding widths were 20mm, 18mm, 16mm and 15mm respectively. According to the final sheet thickness requirements, place 2inchSiC single crystal, 3inchSiC single crystal, 4inchSiC single crystal and 6inchSiC single crystal directly under the four roller groove intervals of 0.65mm, 0.78mm, 0.86 and 0.98mm respectively and fix them on the workbench 8, A graphite thin block is placed between the crystals 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com