A fiber-reinforced cement-based composite material for reinforcement of reinforced concrete structures

A fiber reinforced cement and reinforced concrete technology, which is applied in the field of building materials, can solve the problems of insignificant improvement in the bearing capacity and deformation capacity of reinforced reinforced concrete structures, difficulty in cracking reinforcement of reinforced concrete structures, and unsatisfactory use effects. Compression performance, small crack width, and corrosion reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

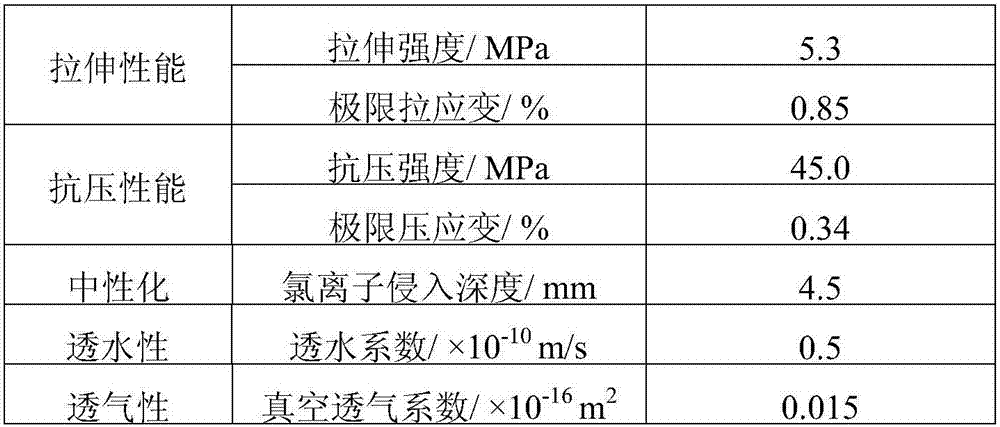

[0040] A high-performance fiber-reinforced cement-based composite material used for strengthening cracked reinforced concrete structures in harsh environments. The composite material is made of cement, silica fume, expansion agent, high-efficiency water reducer, fine sand, fiber and water. The total mass percentage of cement, silica fume, expansion agent, superplasticizer, fine sand and fiber is 77.6%, and water is 22.4% by mass.

[0041] The cement is a low-heat cement with a strength grade of 42.5. The silica fume is microsilica fume (the average particle size is 0.1um) produced by Norway Elkem Company. The expansion agent is a commercially available sulphoaluminate concrete expansion agent and water reducing agent. It is a polycarboxylate high-efficiency water reducer, the fine sand is quartz sand with a diameter less than 0.5mm, and the fiber is high-strength polyethylene fiber produced by Toyobo Corporation in Japan. The mass percentages of the above-mentioned components ...

Embodiment 2

[0048] A high-performance fiber-reinforced cement-based composite material used for strengthening cracked reinforced concrete structures in harsh environments. The composite material is made of cement, silica fume, expansion agent, high-efficiency water reducer, fine sand, fiber and water. The total mass percentage of cement, silica fume, expansion agent, superplasticizer, fine sand and fiber is 83.7%, and the mass percentage of water is 16.3%.

[0049] The cement is low-heat cement with a strength grade of 42.5, the silica fume is micro-silica fume produced by Elkem Company in Norway, the expansion agent is a commercially available sulphoaluminate concrete expansion agent, and the water reducer is a polycarboxylic acid high-efficiency water reducer. The fine sand is quartz sand with a diameter of less than 0.5mm, and the fiber is high-strength polyethylene fiber produced by Toyobo Corporation in Japan. The mass percentages of the above-mentioned components in the total mass o...

Embodiment 3

[0055] A high-performance fiber-reinforced cement-based composite material used for strengthening cracked reinforced concrete structures in harsh environments. The composite material is made of cement, silica fume, expansion agent, high-efficiency water reducer, fine sand, fiber and water. The total mass percentage of cement, silica fume, expansion agent, superplasticizer, fine sand and fiber is 87.8%, and the mass percentage of water is 12.2%.

[0056] The cement is low-heat cement with a strength grade of 42.5, the silica fume is micro-silica fume produced by Elkem Company in Norway, the expansion agent is a commercially available sulphoaluminate concrete expansion agent, and the water reducer is a polycarboxylic acid high-efficiency water reducer. The fine sand is quartz sand with a diameter of less than 0.5mm, and the fiber is high-strength polyethylene fiber produced by Toyobo Corporation in Japan. The mass percentages of the above-mentioned components in the total mass o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com