Preparation method for egg yolk lecithin

A technology of egg yolk lecithin and egg yolk powder, which is applied in the production of edible phospholipid compositions, protein food ingredients, and bulk chemicals, can solve the problems of low yield, high cost, and high temperature, and achieve high extraction efficiency, low cost, and The effect of low extraction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

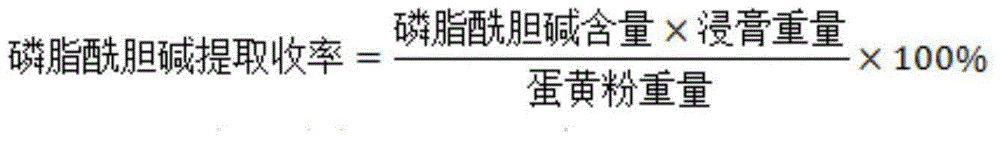

[0031] The preparation method of experimental example 1 egg yolk lecithin

[0032] Pretreatment: After breaking the eggs, use an egg white separator to separate the egg yolks, ripen them at 100-105°C, grind them, continue drying at 70-80°C until the water content is ≤5%, grind them, and pass through a No. 1 sieve to obtain egg yolk powder. Take egg yolk powder 1000g, measure its water content ≤ 5%, extract egg yolk by supercritical carbon dioxide extraction method, extraction temperature is 50 ℃, extraction pressure 35Mpa, CO 2 The flow rate is 50L / h, the extraction time is 120min, the egg oil is removed, and the remaining egg yolk residue is collected.

[0033] Take 500 g of the above-mentioned egg yolk residues, add 4 times the amount of 90% ethanol (i.e. 2000 ml of ethanol), extract at a fixed extraction temperature of 30° C. for 4 times, each time for 1.5 h (continuously stir during the extraction process, and the rotation speed is 150 rpm), and combine the filtrates. Eth...

experiment example 2

[0039] The preparation method of experimental example 2 yellow lecithin

[0040] Pretreatment: After breaking the eggs, use an egg white separator to separate the egg yolks, ripen them at 100-105°C, grind them, continue drying at 70-80°C until the water content is ≤5%, grind them, and pass through a No. 1 sieve to obtain egg yolk powder. Take egg yolk powder 1000g, measure its water content ≤ 5%, extract egg yolk by supercritical carbon dioxide extraction method, extraction temperature is 50 ℃, extraction pressure 35Mpa, CO 2 The flow rate is 50L / h, the extraction time is 120min, the egg oil is removed, and the remaining egg yolk residue is collected.

[0041] Take 500 g of the above egg yolk residues, add 8 times the amount of 90% ethanol (i.e. 4000ml ethanol), extract at a fixed extraction temperature of 30°C for 3 times, each time for 1h (continuous stirring during the extraction process, and the rotating speed is 150 rpm), combine the filtrates, reduce Pressure recovery e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com