Edible vinegar preparation fermentation tower

A fermentation tower and edible vinegar technology, which is applied in the field of edible vinegar preparation fermentation tower, can solve problems such as product quality impact, increased cost burden, and weakened acid production capacity, and achieve the effects of reducing development investment, shortening the research and development cycle, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

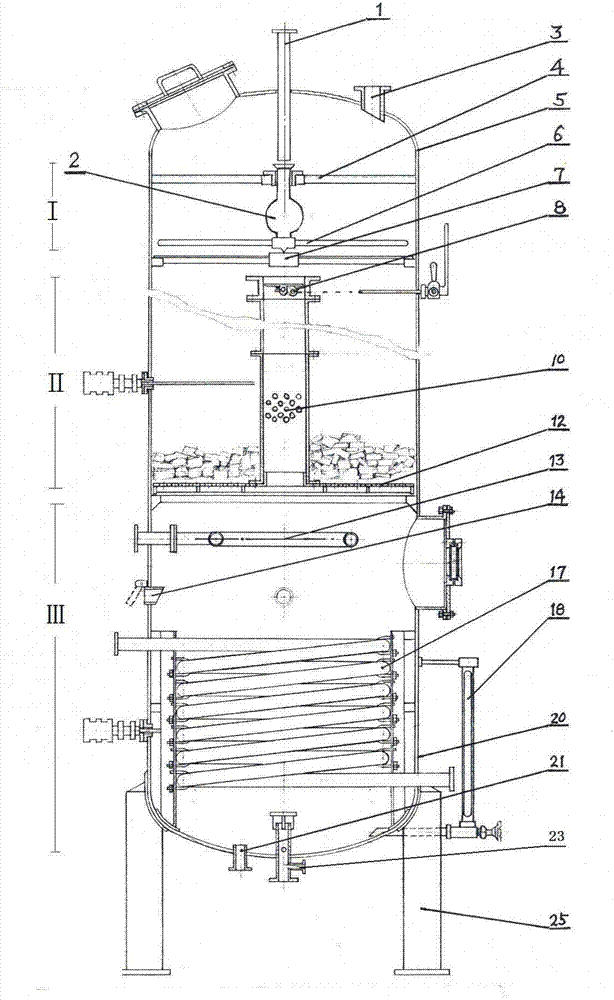

[0008] The edible vinegar preparation and fermentation tower disclosed in the application of the present invention is a vertical tower body 5 supported by a number of feet 25 at the bottom. The tower body 5 is provided with a pouring and feeding mechanism I, an acetic acid bacteria inhabiting section II and a liquid deep layer from top to bottom. Fermentation section III. The feed pipe 1 leads from the top center of the tower body 5 to the leaching feeding mechanism I of the tower body 5, and the discharge port 21 is connected and installed

[0009] At the bottom of tower 5.

[0010] The pouring and feeding mechanism I is composed of a rotating spray pipe 6 and a rotating support rotating spray pipe 6. The central liquid level controller 2 communicates with the rotating spray pipe 6, and the bottom of the liquid level controller 2 is supported by rotation On the support frame 7, the neck of the pipe is arranged on the fixed support 4 through a conical surface rotation. The wine pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com